Hitting delivery dates in oil and gas, bridge, shipyard, and tower work often comes down to one painful reality: thick plate queues build fast, skilled labor is scarce, and a single downtime event can derail an entire week of fit-up and weld schedules. I am Dave Graf, Regional Sales Executive at Mac-Tech, and my role is to be the single point of contact who coordinates the full automation scope, layout, integration, commissioning, and service continuity so leaders can make high-watt fiber laser decisions based on real ROI, not best-case assumptions.

Thick Plate Cutting Bottlenecks and Hidden Costs Driving ROI Pressure

High-watt fiber lasers can remove legacy bottlenecks, but in thick plate the hidden costs often shift downstream into deburr, weld prep, and material movement. Executives usually see the capex and the advertised cut speeds, but the ROI pressure comes from real utilization, rework, assist gas spend, and how many touches it takes to get plate from rack to kit.

Where ROI gets quietly eroded

- Queue time before cutting: 4–12 hours in peak weeks when plate nesting is not synchronized with upstream staging

- Material handling touches: 3–6 touches per plate (crane, staging, load, unload, re-stack, move to fab)

- Deburr and edge cleanup: 1–3 minutes per part on thick profiles, often adding a full shift per week in labor

- Rework drivers: edge taper, dross, and inconsistent pierce quality leading to 2–8% re-cut rates on critical parts

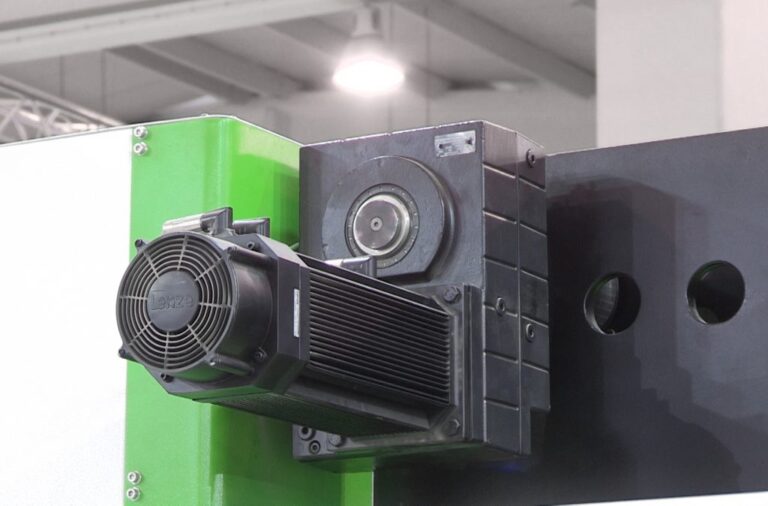

G-FORCE FIBER LASER

HEAVY SERIES ANGLE ROLL BENDING MACHINE

ROI Decision Criteria for High Watt Fiber Lasers in Structural Plate Work

The executive problem is not whether the laser can cut thick plate, it is whether the cell can produce weld-ready kits consistently across shifts with predictable cost per part. In structural environments, assist gas strategy, cut quality expectations, and consumable planning determine whether you realize throughput gains or just move the bottleneck to grinding and weld repair.

Decision criteria to validate before purchase

- Assist gas plan by thickness mix: oxygen vs nitrogen tradeoffs measured by $/hour gas cost and edge condition requirements

- Cut quality definition: acceptable dross height, bevel expectations, and heat-affected edge condition tied to weld procedure requirements

- Real utilization targets: plan around 45–65% utilization in year one unless you already have staged plate flow, trained operators, and stable nesting

- Downstream labor impact: target 20–40% reduction in manual edge cleanup time with clear acceptance criteria and sample approvals

High Watt Fiber Laser Options and Integration Pathways Through a Single Point of Contact

High-watt fiber solutions from HSG Fiber Lasers can be a strong fit for thick plate production when paired with the right loading, unloading, and part handling strategy. The business goal is to convert cutting from a standalone machine into a predictable kitting process that feeds fit-up and welding without firefighting.

As your one-call coordinator, I align the laser cell with upstream and downstream automation where it makes sense, including Prodevco structural processing and complementary fabrication equipment from Akyapak, Liberty, Ermaksan, and Ercolina when the project scope requires it. The integration path is driven by layout, crane coverage, staging zones, and how parts move to welding, not by a single machine spec.

Single point of contact integration scope

- Layout planning: crane paths, plate staging lanes, scrap handling, and finished kit racks with measured travel distances

- Installation and commissioning: coordinated schedules for power, gas, ventilation, and safety, reducing start-up delays by days not weeks

- Training plan: operator, programmer, and maintenance tracks with defined handoff checklists and shift coverage

- Parts and service continuity: one escalation path across the full cell to protect uptime

Reference equipment and configuration options can be reviewed through Mac-Tech’s resources at https://shop.mac-tech.com/.

Implementation Risks in Thick Plate and How to Mitigate Uptime and Quality Impacts

Most thick plate laser ROI misses come from underestimating commissioning realities: pierce consistency, nozzle and consumable discipline, gas supply stability, and downstream acceptance of edge condition. Leaders also overlook that thick plate often runs slower than expected due to quality holds, trial cuts, and operator caution during early adoption.

Risk controls that protect uptime and quality

- Assist gas infrastructure validation: verify supply capacity and pressure stability under peak flow to avoid mid-shift quality drift

- Cut procedure lock-in: approve parameters by thickness family with documented inspection checks (first article and per-shift verification)

- Deburr plan: define which parts require secondary cleanup and set time standards, instead of discovering it after parts hit fit-up

- Utilization realism: plan for a ramp that includes 2–4 weeks of stabilization and operator confidence building

When needed, digital workflow and quoting discipline can also reduce nesting and release volatility. For teams evaluating connected scheduling and utilization visibility, Vayjo can support planning alignment alongside the equipment rollout at https://vayjo.com/.

ROI Metrics to Track After Commissioning in Structural Automation Cells

The executive problem after go-live is proving ROI with operational evidence, not anecdotes. Thick plate lasers often show strong capability on day one, but ROI is determined by stabilized throughput, reduced touches, and fewer downstream interruptions.

Post-commissioning metrics that matter

- OEE and true utilization: track scheduled hours vs cutting hours, targeting 45–65% early and improving with workflow maturity

- Cost per part: include gas, consumables, deburr labor minutes, and re-cut percentage

- First-pass yield: measure rework rate on critical thicknesses, with a goal of reducing re-cut to below 2–3% after stabilization

- Downstream impact: grinding hours per week, weld repair hours, and fit-up delays tied back to edge quality and kitting accuracy

Next Steps for Structural Fabricators Evaluating High Watt Fiber Lasers

The business objective is to make a defendable decision quickly: whether a high-watt fiber laser cell will relieve constraints and produce weld-ready kits at a predictable cost. The fastest path is a structured evaluation using your actual thickness mix, part geometries, gas assumptions, and labor model, then mapping those requirements into a phased integration plan.

A practical evaluation sequence

- Part sampling: 10–20 representative parts across your thickness range with defined acceptance criteria for edge condition and downstream prep

- Layout and handling review: document current touches and travel time, then design a cell flow that reduces moves by 20–40%

- Ramp plan: staffing, training, and maintenance coverage by shift with a commissioning checklist and uptime protection plan

FAQ

What lead times should we expect for a high-watt thick plate laser cell?

Lead times vary by configuration and options, but the schedule risk is usually integration and facility readiness. I coordinate the full timeline, including utilities and staging, so commissioning is not delayed by avoidable gaps.

How do we reduce downtime risk during the first 60 days?

We implement a start-up plan with parameter validation, consumable standards, and maintenance routines by shift. I align service response, spares strategy, and training so the team is not learning under production pressure.

Do we need nitrogen for thick plate, or can we run oxygen?

It depends on thickness mix, edge quality requirements, and downstream weld prep expectations. We model the gas strategy in $/hour and validate with sample parts before finalizing the operating plan.

What training is required for operators and maintenance?

Expect separate tracks for operation, programming, and preventive maintenance with clear proficiency checkpoints. I coordinate OEM training and on-site reinforcement so knowledge survives shift changes and turnover.

How do we measure ROI without overestimating utilization?

We track utilization, cost per part, deburr minutes, and rework rate using a conservative ramp curve. I help set baseline metrics before install so improvements are clear and defensible.

Can Mac-Tech coordinate the full cell, not just the laser?

Yes, that is the point of a single point of contact. I coordinate layout, integration, installation, commissioning, and service continuity across the systems involved so accountability is clear.

Contact Dave Graf for planning, demos, or full project coordination at dave@mac-tech.com, 602-510-5552, or https://shop.mac-tech.com/.

Get Weekly Mac-Tech News & Updates