John Perry

John Perry

Regional Sales Executive, WI

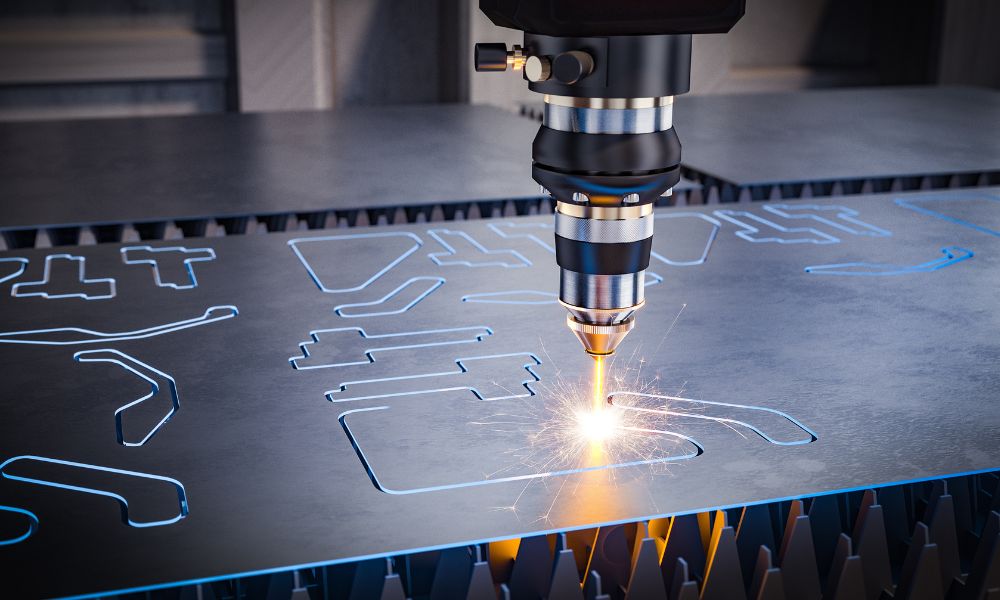

John Perry is a results-focused solutions strategist with over 17 years of senior executive leadership experience. At Mac-Tech, he supports facets of the metal fabrication industry. His extensive expertise in building and expanding manufacturing operations, structures, and market share makes him an invaluable asset to his those he serves.

John’s approach is anchored in creating trusting and cohesive collaborations, driving optimum productivity and process efficiency. His adeptness at understanding the unique needs of his clients allows him to offer tailored solutions that not only meet but exceed their expectations.

At Mac-Tech, John leverages his deep industry knowledge to provide unparalleled service, ensuring that each client benefits from his strategic insights and commitment to excellence. Whether you’re looking to optimize your operations or expand your market presence, John Perry is dedicated to helping you achieve your goals with precision and reliability.