Maximizing Efficiency: Insights from My Sales Journey

Growing up in southern Chicago, I was surrounded by a vibrant community that instilled in me the values of hard work and resilience. My days playing rugby taught me the importance of teamwork and strategy, skills that have proven invaluable in my career as a Regional Sales Executive at Mac-Tech. When I moved to Milwaukee, I brought with me not just the lessons learned on the field but also a commitment to understanding my customers’ needs. I believe that every interaction is an opportunity to build a lasting relationship, and that philosophy drives my approach to sales and service.

In my role, I’ve had the privilege of working with some of the most advanced manufacturing solutions available today. One of the key areas I focus on is the comparison between coil and sheet processing. High-production shops often grapple with the decision of which method to adopt, and I’ve seen firsthand how the right choice can lead to significant cost savings and efficiency gains. For instance, utilizing a downspout roll former or a servo-driven folder can streamline operations, reduce waste, and ultimately enhance productivity. My goal is to equip my customers with the knowledge they need to make informed decisions that align with their specific production goals.

At Mac-Tech, we pride ourselves on our commitment to service and building long-term relationships with our clients. It’s not just about selling a machine; it’s about ensuring that our customers have the support they need to maximize their investment. Whether it’s through training on CNC folders or providing ongoing maintenance for motorized shears, I strive to be a trusted resource for my clients. I believe that when we work together, we can unlock innovative solutions that drive success in their high-production environments.

Cost-Effective Strategies for High-Production Success

When it comes to coil processing versus sheet processing, the conversation often centers around cost-effectiveness. From my experience, coil processing tends to offer a more streamlined approach for high-volume production. The use of slitting and straightening techniques allows for greater material efficiency, and machines like the decoiler and recoiler can significantly reduce handling time. This means that shops can produce more in less time, translating to higher profitability. I’ve seen customers who switch to coil processing experience remarkable improvements in their workflow and bottom line.

However, it’s essential to consider the specific needs of each shop. Sheet processing has its advantages, particularly for smaller runs or specialized projects. Machines like the Combi-Beam folder and various types of motorized folders provide flexibility that can be crucial for certain applications. My role is to help customers evaluate their unique circumstances and determine the best path forward. I often find that a hybrid approach, utilizing both coil and sheet processing, can yield the best results for high-production shops.

At Mac-Tech, we understand that investing in advanced machinery is a significant decision. That’s why we emphasize not only the quality of our equipment but also the importance of ongoing support. Our team is dedicated to providing comprehensive training and maintenance services, ensuring that our customers can maximize the capabilities of their machines. By fostering a culture of collaboration and support, we help our clients navigate the complexities of modern manufacturing, ultimately leading to their long-term success.

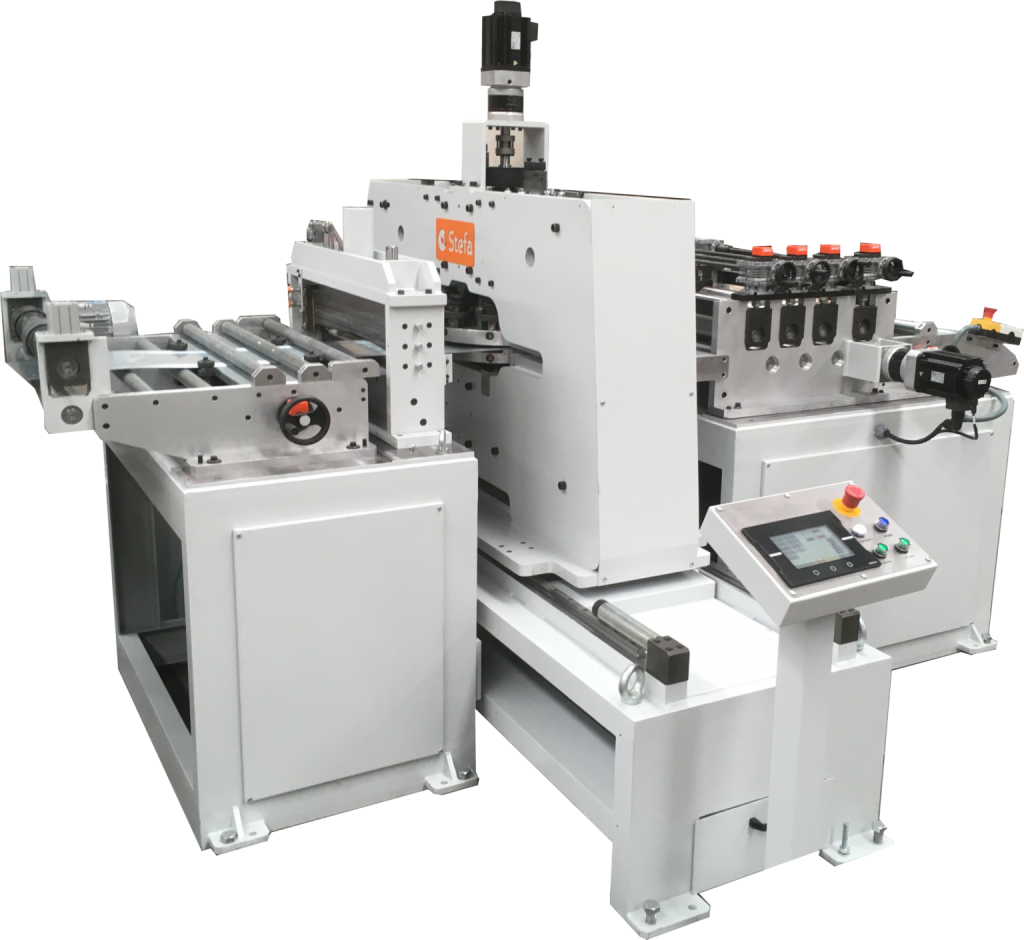

COIL PUNCHING MACHINE

DOWNSPOUT ROLL FORMER

FAQ

What is the ROI for investing in coil processing equipment?

ROI can vary based on production volume and efficiency gains, but many customers see a return within the first year due to reduced material waste and increased output.

How often do machines require maintenance?

Regular maintenance is crucial for longevity. We recommend a schedule based on usage, and our team is always available to assist with upkeep.

Is training provided for new equipment?

Absolutely! We offer comprehensive training sessions to ensure your team is fully equipped to operate the machinery effectively.

What types of materials can I process with your machines?

Our equipment is versatile and can handle a wide range of materials, including various metals and thicknesses, depending on the machine type.

Can I integrate new machines with my existing setup?

Yes, many of our machines are designed to be compatible with existing systems, and we can help assess your current setup for seamless integration.

What support do you offer after the sale?

We pride ourselves on our customer service. Our team is available for troubleshooting, maintenance, and any questions you may have long after the purchase.

How do I know which processing method is right for my shop?

I recommend a thorough evaluation of your production needs and goals. I’m here to help you assess your options and find the best fit for your operations.

I invite you to reach out for further discussion or to schedule a demonstration of our equipment. Together, we can explore how Mac-Tech can help you unlock cost-effective solutions tailored to your high-production needs. Feel free to contact me at pat@mac-tech.com or call me at 414-232-7929. Let’s take your operations to the next level!

Get Weekly Mac-Tech News & Updates