In the world of metal fabrication, precision is paramount. Angle roll forming machines, known for their ability to bend and shape metal with exacting accuracy, are critical assets in many manufacturing operations. However, like any sophisticated machinery, they require regular upkeep to maintain their performance. Preventive maintenance is not just a best practice; it is essential for ensuring the longevity and precision of these machines. This article delves into the importance of preventive maintenance, outlines key steps for maintaining angle roll forming machines, and highlights the benefits of regular maintenance for precision and longevity.

Importance of Preventive Maintenance in Angle Roll Forming

Preventive maintenance is crucial for angle roll forming machines because it helps to avoid unexpected breakdowns and costly repairs. These machines operate under high stress, bending and shaping metal with precision. Over time, components can wear out, leading to inaccuracies in the final product. Regular maintenance ensures that all parts are in optimal condition, reducing the risk of machine failure and maintaining the quality of the output.

Moreover, preventive maintenance helps in identifying potential issues before they become major problems. By conducting routine inspections and servicing, operators can detect signs of wear and tear early. This proactive approach allows for timely interventions, such as replacing worn-out parts or making necessary adjustments, thereby preventing more significant damage and ensuring continuous operation.

In addition to preventing breakdowns and maintaining precision, preventive maintenance also extends the lifespan of angle roll forming machines. Regular servicing keeps the machinery in good working condition, reducing the need for frequent replacements. This not only saves money in the long run but also ensures that the machines remain reliable and efficient, contributing to overall productivity and profitability.

Key Steps for Maintaining Angle Roll Forming Machines

The first step in maintaining angle roll forming machines is to establish a regular maintenance schedule. This schedule should include daily, weekly, and monthly tasks, such as cleaning, lubrication, and inspection of critical components. By adhering to a consistent maintenance routine, operators can ensure that the machines are always in top condition and ready for use.

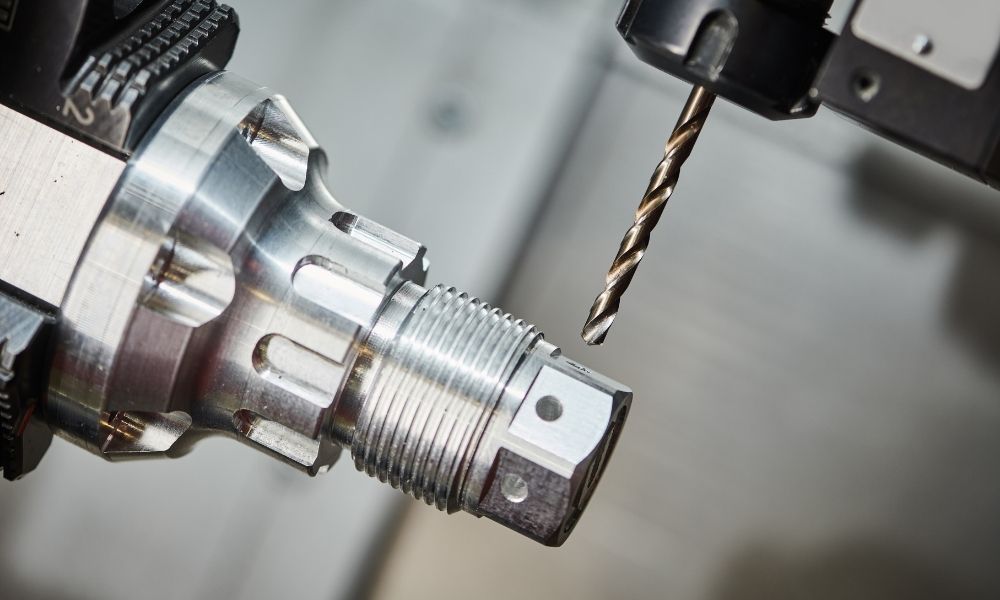

Another essential step is to conduct thorough inspections of the machine’s components. This includes checking for signs of wear and tear, such as cracks, corrosion, or misalignment. Special attention should be given to the rollers, bearings, and hydraulic systems, as these are critical for the machine’s performance. Any issues identified during inspections should be addressed promptly to prevent further damage and maintain the machine’s accuracy.

Finally, proper training for operators is vital for effective maintenance. Operators should be knowledgeable about the machine’s operation and maintenance requirements. They should be trained to recognize early signs of potential problems and know how to perform basic maintenance tasks. Providing ongoing training and support ensures that operators are equipped to keep the machines running smoothly and efficiently.

My Definitive Take on Prodevco vs. Traditional Beam Coping: Faster Output, Lower Labor, and Higher Profits

Leading the Charge in Structural Steel Fabrication: Leveraging Prodevco’s Robotic Beam Coping and Drilling for Unmatched Efficiency and Profitability.

Benefits of Regular Maintenance for Precision and Longevity

Regular maintenance of angle roll forming machines offers numerous benefits, including enhanced precision. When machines are well-maintained, they operate more accurately, producing consistent and high-quality results. This precision is crucial for meeting the stringent requirements of metal fabrication projects and ensuring customer satisfaction.

Another significant benefit is the extended lifespan of the machines. Regular maintenance helps to prevent excessive wear and tear, reducing the likelihood of major breakdowns. By keeping the machines in good working condition, operators can maximize their investment and avoid the high costs associated with frequent replacements or extensive repairs.

Furthermore, regular maintenance contributes to overall operational efficiency. Well-maintained machines are less likely to experience downtime, ensuring continuous production and minimizing disruptions. This leads to increased productivity and profitability, as the machines can operate at their full potential without unexpected interruptions.

Preventive maintenance is not just a recommendation; it is a necessity for ensuring the precision and longevity of angle roll forming machines. By following a regular maintenance schedule, conducting thorough inspections, and providing proper training for operators, manufacturers can protect their investment and maintain the high performance of their machinery. If you’re looking to maintain or improve the performance of your metal fabrication equipment, I’m here to help. Feel free to reach out to me to discuss your service needs.

FAQ

What is the most critical aspect of preventive maintenance for angle roll forming machines?

The most critical aspect is establishing and adhering to a regular maintenance schedule that includes cleaning, lubrication, and inspection of critical components.

How often should angle roll forming machines be serviced?

Angle roll forming machines should be serviced regularly, with daily, weekly, and monthly maintenance tasks to ensure they remain in optimal condition.

What are the signs that an angle roll forming machine needs maintenance?

Signs include unusual noises, decreased precision, visible wear and tear on components, and hydraulic system issues.

Can preventive maintenance extend the lifespan of angle roll forming machines?

Yes, regular preventive maintenance can significantly extend the lifespan of these machines by preventing excessive wear and tear and avoiding major breakdowns.

Why is operator training important for machine maintenance?

Proper training ensures that operators are knowledgeable about the machine’s operation and maintenance requirements, enabling them to recognize early signs of potential problems and perform basic maintenance tasks effectively.

What components of angle roll forming machines require the most attention during maintenance?

The rollers, bearings, and hydraulic systems require the most attention, as they are critical for the machine’s performance and precision.

How does regular maintenance contribute to operational efficiency?

Regular maintenance minimizes downtime, ensuring continuous production and reducing disruptions, which leads to increased productivity and profitability.

Get Weekly Mac-Tech News & Updates