As National Sales Executive at Mac-Tech, I have had the privilege of working closely with metal roofing and downspout manufacturers across Indiana to optimize their fabrication lines. Over the years, I have seen firsthand how identifying and eliminating bottlenecks in production not only boosts efficiency but also elevates product quality. Understanding the nuances of cut, fold, and form machinery is essential for uncovering hidden inefficiencies that can slow down fabrication processes. My experience enables me to provide targeted solutions that help shops streamline operations and maintain a competitive edge.

Leveraging Cut, Fold, and Form Machinery Expertise to Identify Fabrication Bottlenecks

In my role, I frequently analyze fabrication lines to pinpoint where delays or inefficiencies occur. Cut, fold, and form machinery are the backbone of metal roofing component production, and each stage presents unique challenges. For example, outdated cutting equipment may cause inconsistent part dimensions, leading to rework or assembly delays. Similarly, fold machines that are not properly calibrated can produce components that do not fit correctly, creating downstream workflow interruptions. By closely examining machine performance and process flow, I can identify these subtle issues that often go unnoticed in day-to-day operations.

One key insight I have gained is the importance of integrating machine diagnostics with operator feedback. Operators often notice performance dips or unusual machine behavior before it becomes a major problem. Combining this qualitative information with quantitative data from machine sensors allows me to develop a comprehensive picture of bottlenecks. This approach ensures that solutions address root causes rather than symptoms, resulting in more sustainable improvements.

Furthermore, understanding the specific requirements of metal roofing and downspout fabrication is critical. Each product line may have distinct material thicknesses, profiles, and tolerances. Tailoring machinery settings and workflows to these specifications helps prevent bottlenecks caused by improper machine use or mismatched equipment capabilities. This deep technical knowledge is what enables me to offer precise recommendations that improve throughput without sacrificing quality.

Customized Mac-Tech Solutions Enhancing Workflow in Roofing Component Production

At Mac-Tech, we recognize that no two fabrication shops are exactly alike, which is why we emphasize customized solutions. After identifying bottlenecks, I collaborate with clients to design equipment upgrades or process adjustments that are uniquely suited to their production environment. For instance, we may recommend retrofitting existing cut-to-length lines with advanced control systems to improve accuracy and reduce scrap rates. These targeted enhancements often lead to immediate and measurable improvements in cycle times.

In addition to hardware upgrades, Mac-Tech provides comprehensive training to ensure operators and maintenance personnel fully understand new technologies and best practices. This training is vital for sustaining gains made from machinery improvements and minimizing downtime caused by operator error or maintenance delays. I personally oversee many of these training sessions to ensure they address the specific challenges our clients face.

STEFA FOLDING MACHINE VH

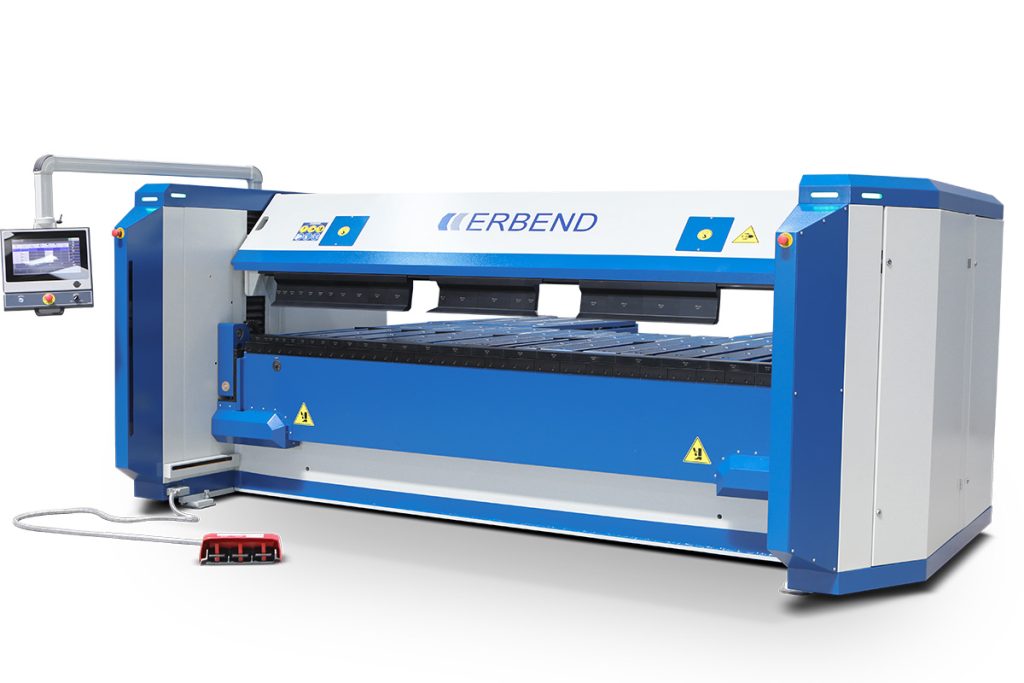

ERBEND SFA

Our commitment extends beyond installation and training. Mac-Tech offers ongoing support and preventive maintenance programs designed to keep fabrication lines running smoothly. By maintaining close relationships with our customers, we can proactively identify emerging bottlenecks and recommend adjustments before they impact production. This partnership approach is central to how we help Indiana metal roofing manufacturers stay efficient and competitive.

What are common signs of bottlenecks in metal roofing fabrication lines?

Common signs include frequent machine stoppages, inconsistent part quality, increased scrap rates, and delayed order fulfillment.

How often should cut, fold, and form machinery be calibrated?

Calibration frequency depends on usage but typically should occur monthly or after significant production runs to maintain precision.

Can Mac-Tech customize machinery for unique metal profiles or thicknesses?

Yes, we specialize in tailoring equipment settings and components to accommodate a wide range of profiles and material specifications.

What training does Mac-Tech provide for new equipment installations?

We offer hands-on operator training, maintenance workshops, and detailed process documentation to ensure smooth adoption.

How does Mac-Tech support ongoing maintenance to prevent bottlenecks?

We provide scheduled preventive maintenance services and remote monitoring solutions to detect and address issues early.

Is it possible to upgrade existing machinery rather than replace it entirely?

Absolutely. We often retrofit current equipment with modern controls and components to improve performance cost-effectively.

What role do operators play in identifying fabrication line inefficiencies?

Operators are crucial as they can detect subtle changes in machine behavior and provide insights that help diagnose bottlenecks.

Get Weekly Mac-Tech News & Updates