I’m Nicole Salato, Service and Parts Lead at Mac-Tech. Every day I help shops keep press brakes, lasers, and shears productive with dependable service and the right parts at the right time. My approach is simple: spot wear early, act before it becomes downtime, and source parts that fit, function, and arrive when you need them.

Early Wear Indicators by System: Hydraulics, Motion, Electrical, and Cooling on Press Brakes, Lasers, and Shears

Hydraulics

- Press brakes and hydraulic shears: rising oil temperature, slow or uneven ram return, pressure drift, audible pump whine, filter clog indicators creeping up, hose sweating or cracking, cylinder rod seal weeping, and ram leveling offsets that need frequent correction.

- Lasers if equipped with hydraulic pallet changers or clamps: small leaks around fittings, unpredictable clamp force, and power unit running hotter or louder than usual.

Motion

- Press brakes: backgauge repeatability slipping beyond 0.004 in, axis following error alarms, unexpected vibration in X or R, noisy ball screws, linear guides feeling gritty despite lubrication, and growing backlash during bend corrections.

- Lasers: shuttle table that jerks on travel, gantry cable carrier cracking, rail contamination causing servo hunting, and sudden loss of cut accuracy even after nozzle and lens checks.

- Shears: increasing burr at the cut edge, inconsistent blade gap results, blade carrier misalignment, and stroke inconsistencies that show up as rhythmic marks.

Electrical and CNC

- Nuisance trips on breakers, contactor chatter, warm spots on drives or power supplies, frayed cable carriers, intermittent proximity sensors, and encoders dropping counts.

- CNC controls: low battery warnings, louder cabinet fans, power supply ripple causing random resets, unexplained parameter mismatches, and grounding issues that create intermittent I/O faults.

Cooling and Thermal Management

- Press brakes: hydraulic cooler unable to hold temperature, fouled heat exchangers, or reduced airflow across cabinet fans.

- Lasers: chiller struggling to hold setpoint, increased delta-T across the heat exchanger, pump cavitation, dirty strainers, rising water conductivity or algae in the DI loop, and any dew point or condensation warnings.

- Shears: motor fans clogged with dust, cabinet filters loaded, and thermal trips after sustained runs.

ERMAKSAN SPEED BEND PRO

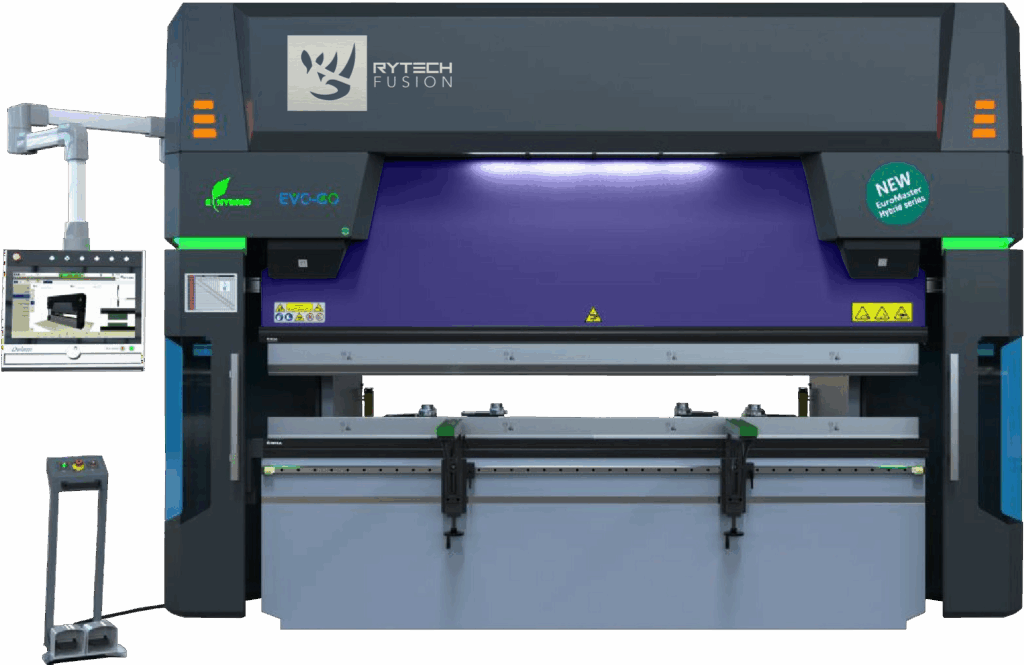

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Preventative Maintenance You Can Do Now: Daily, Weekly, and Monthly Checks That Cut Unplanned Stops

Daily

- Walk-around inspection for leaks, loose fasteners, and unusual noises.

- Verify hydraulic oil level and look for foaming or discoloration.

- Clean optics and nozzles on lasers, wipe rails and covers on moving axes, and clear air intakes.

- Test E-stops, light curtains, and interlocks.

- Drain water separators and check air pressure stability.

Weekly

- Check filter indicators for hydraulics and cabinet air; replace if near limit.

- Lubricate backgauge screws and linear guides per the manufacturer schedule.

- Verify axis zeroing and repeatability with a simple go/no-go check or gauge blocks.

- Inspect cable carriers and connectors for rubs and looseness.

- Clean chiller strainers, check coolant level and concentration, and confirm setpoints.

Monthly

- Take a hydraulic oil sample for particulate and water; trend results.

- Verify system pressure with a calibrated gauge and record cycle times under a standard load.

- Inspect cylinder rods, hoses, and fittings; tighten to spec if required.

- Check drive belts, couplings, and bolts on motors and pumps.

- Back up CNC parameters and programs; confirm control batteries are within date; vacuum electrical cabinets and verify fan operation.

- Perform a thermal check of drives, transformers, and contactors to catch hot spots.

Parts Sourcing That Keeps You Running: OEM, Proven Alternatives, Lead Times, and Smart Stocking

- OEM vs proven alternatives: I start with OEM specifications, then validate proven alternatives when they meet performance, safety, and compatibility requirements. This includes pressure ratings, seal material, electrical ratings, firmware compatibility, and mounting interfaces. I do not substitute on safety-critical parts or where certification would be compromised.

- Lead time expectations: common wear items like filters, sensors, contactors, nozzles, lenses, and seals are often available within 1 to 3 business days. Pumps, cylinders, servo drives, and custom boards typically run 5 to 15 business days. I can often expedite in critical cases.

- Smart stocking: keep A-level spares on site based on impact and lead time. Examples include hydraulic filters, seal kits, hoses, proximity sensors, encoders, fuses, contactors, belts, cable-carrier links, optics and ceramics for lasers, and cabinet fan filters. For high-usage cells, consider a backup power supply, a spare drive or amplifier, and a complete backgauge sensor set.

- How I help: I confirm part numbers by machine serial, cross-check compatibility, provide options with lead times and cost, and advise on minimum on-hand quantities tied to your run schedule. I also bundle kits to reduce freight and ensure everything needed for a repair arrives together.

Coordinated Service Made Simple: When to Schedule and How Nicole Salato at Mac-Tech Can Help (nicole@mac-tech.com)

- Best timing: schedule PM before peak production, after tooling changes, or when quality trends start drifting. Hydraulic press brakes benefit from semiannual PM. High-duty lasers often need quarterly checks on optics, motion, and cooling.

- Easy intake: send machine type, serial number, symptoms, alarm history, recent changes, and clear photos or short videos. I use that to triage quickly and pre-stage parts.

- Clear plan: I provide a prioritized action list, parts availability, and a service window that works with your shift plan. If a same-day fix is unlikely, I propose a temporary workaround to keep you producing safely.

- Fast turnaround: I coordinate parts, technician dispatch, and any remote support needed so you are not juggling vendors. My goal is one call, one plan, no surprises.

FAQ

How fast can you get common parts?

- Italicized answer: Most filters, sensors, contactors, optics, and seal kits ship in 1 to 3 business days. Pumps, cylinders, drives, and custom boards typically take 5 to 15 business days. Expedited options are often available.*

What are the early signs my machine needs service?

- Italicized answer: Rising temperatures, slower cycles, new vibrations, repeatability drifting, more frequent alarms, oil or coolant discoloration, and anything that suddenly becomes louder or inconsistent.*

What preventative maintenance delivers the biggest return?

- Italicized answer: Oil cleanliness and cooling on hydraulics, clean optics and stable cooling on lasers, and backgauge lubrication with cabinet air management across all machines. These stop most unplanned downtime before it starts.*

How do you handle CNC control parts and firmware?

- Italicized answer: I verify model and serial, check firmware dependencies, confirm connector and parameter compatibility, and provide backup and restore steps so installation is smooth and safe.*

What is Mac-Tech’s typical response and ordering process?

- Italicized answer: Send details to nicole@mac-tech.com. I triage the issue, confirm parts and lead times, issue a quote, and schedule service. Many parts ship same or next business day after approval.*

- Can you help build a spare parts plan for my shop?

- Italicized answer: Yes. I map your machines, usage, and risk, then propose A-B-C spare tiers with min-max levels and reorder points tied to lead time and criticality.*

Keeping your equipment productive is a team effort. If you want help setting up a preventative plan, coordinating service, or sourcing the right parts with dependable timelines, I am here to support you. Reach out to me at nicole@mac-tech.com and let’s keep your machines running strong.

Get Weekly Mac-Tech News & Updates