I am Pat O’Neill, National Sales Executive at Mac-Tech, and for more than two decades I have helped metal roofing and downspout manufacturers modernize cut, fold, and form operations. In shops across Indiana, the right CNC control retrofit has become the fastest path to better throughput, tighter tolerances, and less scrap on profiles that your customers judge every day on fit and finish. This article explains how I leverage Section 179 to fund those upgrades, drawing on our guide, Using Section 179 to Cover CNC Control Assessments and Retrofits in Indiana Facilities, and how my team turns a retrofit plan into production results with minimal disruption.

Section 179 in Indiana put to work: funding CNC control retrofits on press brakes, long folders, roll formers, and cut-to-length lines for roofing and downspout production

Section 179 lets you expense qualifying equipment and software that is purchased and placed in service within the tax year, which includes CNC control retrofits, drives, PLCs, HMIs, and the installation work that makes them production ready. Indiana generally conforms to federal Section 179 rules for most taxpayers, so a properly documented retrofit can create a same‑year tax deduction that offsets the project cost and accelerates payback. I coordinate the project timeline with your CPA so placed‑in‑service dates align with your fiscal plans and you know exactly what support documentation you will receive from Mac‑Tech.

On press brakes and long folders, modern controls unlock angle correction, auto bend sequencing, and quick tool recall that reduce trial bends and eliminate guesswork on trims, panels, and accessories. Upgrading the control and backgauge logic typically cuts changeover time and lifts first‑part accuracy, which matters when you are producing a wide mix of flashing details and hems in short runs. The result is consistent angles across batches, fewer rework loops, and better edge quality that is visible on finished roofs and gutters.

Roll formers and cut‑to‑length lines benefit from PLC and HMI upgrades that stabilize line speed, improve length accuracy through better encoder handling, and bring recipe management to the operator level. On roofing panels and downspouts, tighter control of acceleration and shear timing reduces coil waste at starts and stops and improves cut‑length consistency. Section 179 can cover the controls, software, panels, and integration labor in a single project scope, but I always advise clients to confirm details with their CPA because specific limits and phase‑outs change by tax year.

Assessment to scope: how I evaluate legacy controls, backgauges, and PLCs to plan ROI-driven upgrades for cut, fold, and form operations

Every retrofit begins with a structured onsite assessment. I document make, model, year, axes, hydraulic condition, safety interfaces, and the health of the electrical cabinet. I review the PLC, drive family, I/O, and backgauge mechanics, then capture baseline metrics such as bend cycle time, setup time, first‑part yield, and rework rates so we can quantify the financial impact of the upgrade.

For cut‑to‑length and roll forming, I measure current length variance, shear timing, encoder performance, and flying die motion where applicable. We run sampled panels and downspouts to check profile stability, edge bow, and end squareness. On press brakes and folders, I use angle coupons, measure springback on common roofing alloys, and observe operator inputs to identify where modern features like angle measurement, material libraries, or 2D programming will remove the most waste.

I then translate findings into a scope of work and ROI model. The scope specifies the control platform, PLC and HMI, servo or drive changes, new feedback devices, safety circuit upgrades, and any backgauge or crowning enhancements. The ROI model includes scrap reduction, minutes of setup saved per run, improved first‑part yield, and projected OEE lift, along with a timeline that meets placed‑in‑service requirements for Section 179. You receive a written assessment that references our Indiana‑specific guidance and sets clear milestones for approvals, staging, install, and operator training.

ROBOTIC SOLUTIONS

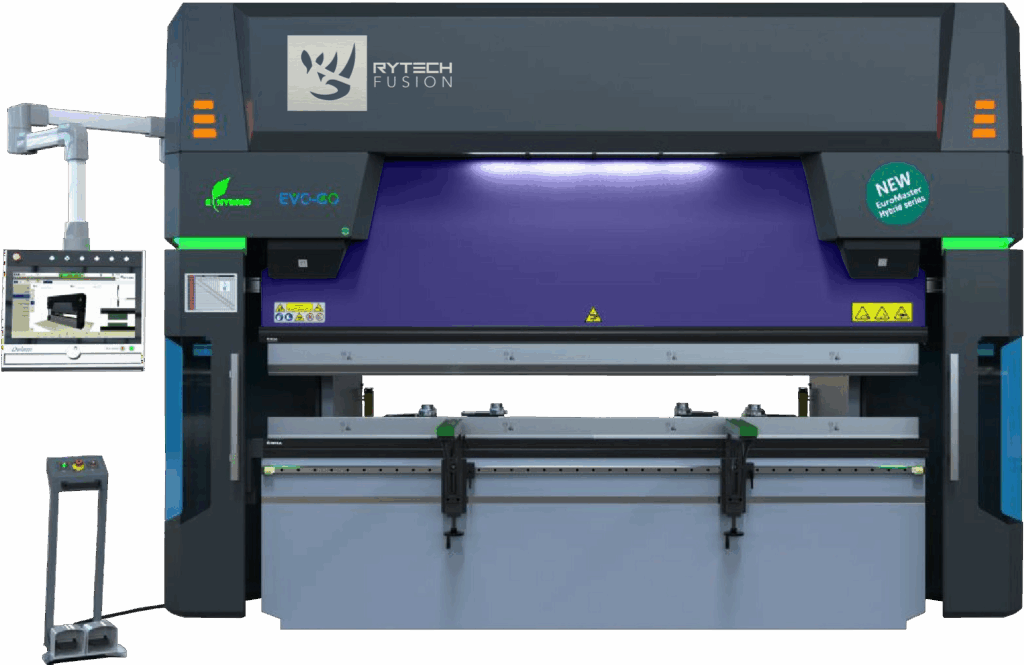

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Mac-Tech’s turnkey path for Indiana facilities: tailored control kits, production-friendly installs, operator training, and CPA-ready paperwork to maximize Section 179 benefits

I build retrofit kits around your machinery and product mix. For press brakes and long folders, that may include a modern CNC control with offline programming, new amplifiers, encoders, and safety interfaces tied to light curtains and foot pedal logic. For roll formers and cut‑to‑length lines, the kit typically includes a new PLC, HMI, drives, recipe management, encoder upgrades, and shear or cutoff synchronization. Every panel is pre‑wired and bench tested to shorten onsite time.

We plan production‑friendly installs so you keep commitments to customers. My team stages the panel build, pre‑terminates harnesses, and schedules cutover on weekends or during low‑load shifts. We perform functional acceptance tests with your parts, import material libraries and recipes, verify direction and scale of axes, validate length accuracy, and leave you with a tested backup of all parameters and programs. Remote support and onsite follow‑up are part of the plan, not an afterthought.

Training and documentation close the loop. Your operators and leads receive hands‑on instruction focused on your parts, with quick‑reference job aids that standardize best practices. For Section 179, we provide CPA‑ready paperwork, including itemized invoices that separate equipment and labor, serial numbers, software licenses, freight and install detail, a placed‑in‑service statement, and our W‑9. I coordinate with your accounting team so the documentation aligns with your capitalization policies and year‑end deadlines.

FAQ

Do CNC control retrofits qualify for Section 179 in Indiana?

In most cases yes, when the hardware and software are purchased and placed in service within the tax year and used predominantly for business. Confirm with your CPA for your situation and current limits.

How long will my machine be down during a retrofit?

Typical cutover runs from one to three days per machine, with pre‑build and bench testing done offsite to minimize downtime.

Can my older press brake or long folder accept a modern control and backgauge logic?

Often yes. If the mechanics are sound, we can integrate new controls, drives, and feedback while retaining the frame and gauge axes. I verify compatibility during the assessment.

What improvements should I expect on cut‑to‑length accuracy after a PLC and encoder upgrade?

Most lines see tighter length tolerance, more consistent shear timing, and reduced coil scrap at starts and stops, especially on short blanks.

What training is included for operators and maintenance staff?

Hands‑on operator training, job aids, and maintenance walk‑throughs covering backups, parameter management, and basic diagnostics are standard.

Can you customize controls to my roofing profiles and downspout recipes?

Yes. We build material libraries, angle corrections, and recipe sets around your alloys, gauges, and common parts so operators can run repeat jobs with confidence.

Do you support financing along with Section 179 planning?

Yes. We can coordinate third‑party financing and align install timing to meet placed‑in‑service requirements for the deduction.

I am committed to helping Indiana manufacturers turn control retrofits into measurable gains in accuracy, uptime, and throughput while making Section 179 work for the business. If you want to walk a line, review an assessment, or map an install to your year‑end plan, I would value the conversation. Reach me at pat@mac-tech.com and let us put a practical, ROI‑driven roadmap in place for your facility.

Get Weekly Mac-Tech News & Updates