From my earliest days growing up on the south side of Chicago, I learned the value of hard work, straight talk, and putting the customer first. That mindset has guided my journey from the shop floor to my role today as National Product Manager and Regional Sales Executive at Mac-Tech. Each week, I partner with roofing and fabrication businesses across the country, helping them identify the right technology to upgrade their production lines. Whether it’s folders, shears, slitters, or panel benders, I’m committed to providing practical solutions that boost efficiency and product quality. Let’s look at how coil straightening technology can make a measurable difference in your operation.

Leveraging Decades of Experience to Enhance Coil-Fed Production Efficiency

In coil-fed production, the quality of your finished product is only as good as the consistency of your incoming material. Over the years, I’ve seen how improper straightening can lead to headaches down the line: edge waviness, camber, and out-of-square parts that waste time and material. At Mac-Tech, we help customers evaluate and specify straighteners that integrate seamlessly with their existing decoilers, slitters, and folders. The right equipment ensures your coil stock is flat and stress-free before it enters the next process, reducing manual rework, scrap, and costly downtime. Automation with advanced straighteners also means fewer hands-on adjustments, leading to tighter tolerances and higher throughput.

Evaluating Coil Straightening Solutions for Precise Slitting, Forming, and Folding

Not all straighteners are created equal. The choice between entry-level pinch rollers, precision levelers, and high-capacity servo-driven straighteners depends on your product mix and required tolerances. For example, precision slitting demands consistent strip width and flatness to prevent downstream jams or misfeeds. I often walk customers through side-by-side comparisons, highlighting how advanced straighteners with more rolls and tighter roll spacing can dramatically improve flatness and edge quality. This is especially critical when feeding into high-speed folding or panel forming lines, where even slight coil set or crossbow can throw off your finished dimensions.

Upgrading Equipment: Key Considerations for Improved Speed and Product Consistency

When evaluating an equipment upgrade, it’s important to look beyond just the straightener itself. At Mac-Tech, we take a holistic approach, considering how new technology will interface with your existing folders, shears, slitters, and roll formers. Modern straighteners with automatic roll adjustment reduce setup time and operator error. Pairing these with servo-driven folders or advanced panel benders can unlock new levels of speed and repeatability. In one recent project, a customer upgraded both their straightener and folder, cutting changeover time by 40% and boosting daily output without increasing labor costs. Investing in the right combination of equipment pays off quickly in both product consistency and reduced overtime.

DOWNSPOUT ROLL FORMER

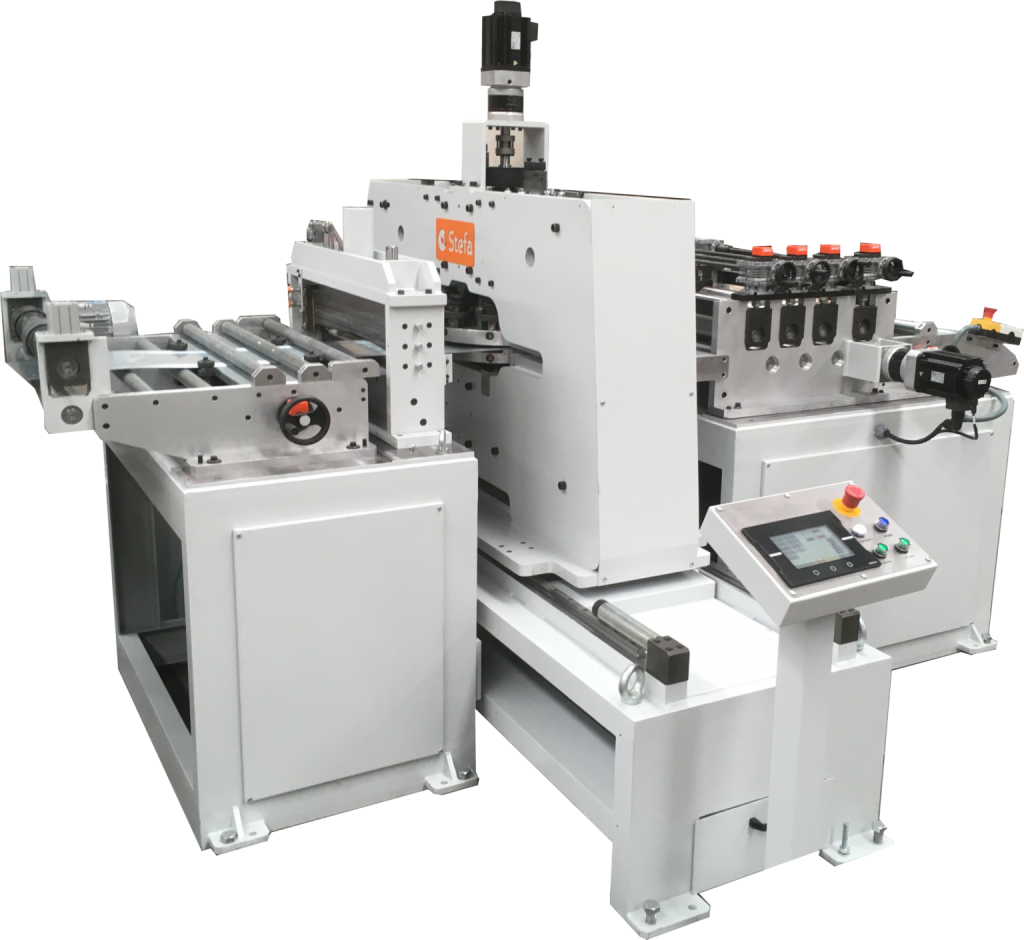

COIL PUNCHING MACHINE

Reducing Waste and Downtime with Advanced Coil Straightening Technology

Scrap and downtime eat into your margins, especially when material prices are volatile. Advanced coil straighteners help minimize both by delivering uniform, stress-relieved material that feeds smoothly into downstream processes. Features like automated thickness sensing, quick-change roll cassettes, and integrated diagnostics keep your line running reliably. I’ve seen customers reduce waste by up to 15% simply by upgrading their straightener, thanks to improved flatness and fewer jams. Less manual intervention also means your skilled operators can focus on higher-value tasks, further reducing the risk of costly mistakes.

Tailoring Coil Processing Solutions to Meet Unique Fabrication Challenges

Every shop has its own set of challenges, whether it’s handling pre-painted coil for architectural panels, thick-gauge material for structural components, or delicate stainless for custom fabrication. My role is to help you navigate the maze of options—folders, shears, slitters, decoilers, downspout roll formers, panel benders—and match you with a coil straightening solution that fits your workflow and budget. We offer on-site demos, virtual walk-throughs, and side-by-side machine comparisons to ensure you’re making the best long-term investment. Custom configurations, retrofits, and automation packages are all on the table, tailored to your unique production mix.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent breakdowns, excessive scrap, or struggling to meet tighter tolerances, it’s time to consider an upgrade. Newer machines offer better automation, quicker setups, and improved consistency, often paying for themselves in reduced labor and material waste.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer faster, quieter operation and more precise angle control. They’re ideal for shops running a high mix of parts or needing rapid changeovers. Hydraulic systems still have their place for heavy-gauge work, but servos are quickly becoming the standard for speed and accuracy.

What’s the difference between a combi-beam and double folder?

A combi-beam folder gives you the flexibility to switch between straight and radius bending in one setup, while a double folder allows for bending both up and down without flipping the part. Your choice depends on your product mix and desired efficiency.

What are signs a roll forming line is no longer cost-effective?

If you’re facing frequent downtime, excessive tooling wear, or your line can’t keep up with demand, it may be time to evaluate an upgrade. Modern lines can triple your throughput with less labor and higher accuracy.

Can coil straightening really reduce my scrap rates?

Absolutely. Proper straightening eliminates coil set, camber, and edge waviness, leading to fewer rejected parts and smoother downstream processing. Most customers see a measurable reduction in waste almost immediately after upgrading.

How do I know which straightener is right for my application?

We start with your material specs, product tolerances, and production volume. From there, we can recommend the right roll configuration, automation level, and integration options to maximize your ROI.

Ready to see how advanced coil straightening can transform your production line? Let’s talk about a tailored solution for your operation. Reach out to me directly at pat@mac-tech.com or 414-232-7929, or use the form below to schedule a walkthrough, request a demo, or get a quote on your next upgrade.

Get Weekly Mac-Tech News & Updates