Rytech Press Brakes: Compact, Energy-Efficient Precision for Illinois Shops

Rytech Press Brakes offer Illinois job shops compact, energy-efficient solutions, enhancing precision and repeatability while reducing costs. Contact Mac-Tech: 888-MAC-9555

Rytech Press Brakes offer Illinois job shops compact, energy-efficient solutions, enhancing precision and repeatability while reducing costs. Contact Mac-Tech: 888-MAC-9555

Accelerate defense capacity with high-speed, heavy-duty brakes; plan year-end buys to capture Section 179 and grow efficiently. Joe Ryan President, Mac-Tech joe@mac-tech.com | 414-477-8772 | 888-MAC-9555

In the article, Patrick O’Neill discusses how businesses can enhance their return on investment by utilizing Section 179 to upgrade decoilers and shears. He emphasizes the benefits of improved production efficiency through advanced roll forming, folding, and coil-fed fabrication systems. By leveraging these technologies, companies can streamline operations and increase productivity. Pat offers his expertise to guide customers in selecting the right equipment for their needs. For further assistance, contact Pat O’Neill at pat@mac-tech.com or 414-232-7929.

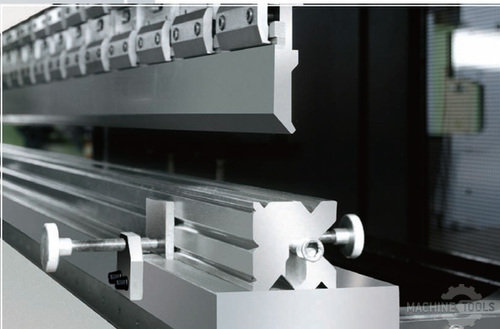

John Perry, Regional Sales Executive at Mac-Tech, provides insights into the efficiency and precision of electric versus hybrid Rytech press brakes. He highlights the benefits and drawbacks of each type, helping manufacturers make informed decisions based on return on investment. By comparing the operational costs, energy consumption, and precision capabilities, Perry guides manufacturers in selecting the best equipment for their needs, including lasers, press brakes, and automation systems. For further assistance, he can be reached at: John Perry Regional Sales Executive, Mac-Tech jperry@mac-tech.com

Adam Quoss, VP of Sales at Mac-Tech, explores how Akyapak drill lines enhance precision and efficiency in fabrication. Offering a hands-on perspective, he provides practical guidance for decision-makers looking to modernize operations, emphasizing the technology’s ability to streamline processes, reduce errors, and boost productivity in manufacturing environments.

Kyle Bialozynski leverages his field experience to offer Wisconsin shops lean fabrication and cost-effective modernization with Rytech press brakes. Committed to customer satisfaction, he delivers smart solutions. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

Nicole Salato spotlights press brake controller warning signs and helps you stay ahead of breakdowns with proactive service and smart parts sourcing. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

The article by Dave Graf, Regional Sales Executive at Mac-Tech, highlights how Ercolina Benders and laser-cut profile automation can significantly enhance ROI in structural steel fabrication. Tailored for the oil & gas, shipbuilding, bridge, and tower construction industries, Dave outlines end-to-end automation solutions that streamline production, reduce labor costs, and improve precision. By integrating these technologies, companies can achieve greater efficiency and profitability. For more information, contact Dave Graf at dave@mac-tech.com or 602-510-5552.

Akyapak’s variable-geometry plate rolls enhance precision in Illinois tank and vessel fabrication, boosting accuracy and consistency in heavy-duty production. Contact Mac-Tech: 888-MAC-9555

End of content

End of content