My Approach to CNC & Metal Fabrication Solutions at Vartek

Customized CNC solutions for superior customer success. Adam Quoss Vice President of Sales, Mac-Tech aquoss@mac-tech.com

Customized CNC solutions for superior customer success. Adam Quoss Vice President of Sales, Mac-Tech aquoss@mac-tech.com

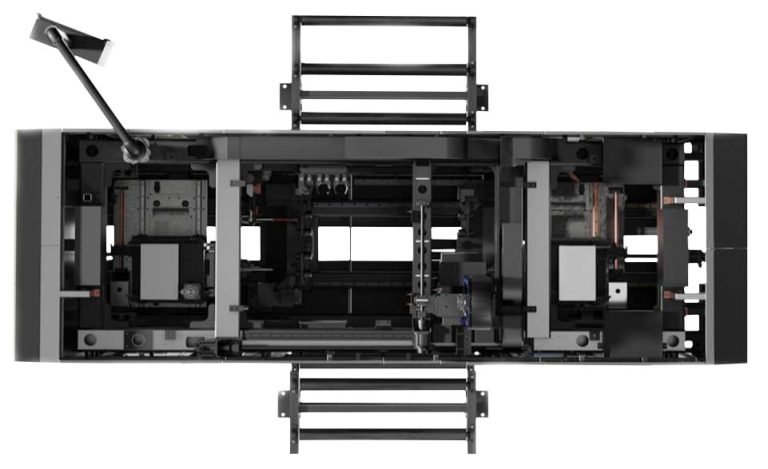

**Overview** In “Revolutionizing Laser Cutting Efficiency: How Automated Material Handling Transforms Sheet, Plate, and Tube Operations,” John Perry, Regional Sales Executive at Mac-Tech, delves into the critical intersection of automation and laser cutting technology. Drawing on his extensive industry expertise, John highlights how integrating advanced automated material handling systems can significantly enhance the efficiency of press brakes and laser operations. He addresses a pressing challenge faced by manufacturers: the need for streamlined workflows that minimize downtime and optimize resource allocation. By adopting innovative tooling solutions, businesses can not only overcome these obstacles but also unlock substantial productivity gains. Decision-makers seeking to stay competitive in a rapidly evolving market will find valuable insights and actionable strategies in this article, inspiring a transformative approach to their operations.

Discover how advanced roll forming systems can enhance your product line with custom profiles. I’m here to help you succeed in metal fabrication. – Pat O’Neill, Mac-Tech (pat@mac-tech.com, 414-232-7929)

Dave Graf, Regional Sales Executive at Mac-Tech, presents a game-changing perspective on optimizing structural steel processing. This article delves into Akyapak’s cutting-edge beam drilling solutions, which promise to revolutionize operations across critical sectors such as structural steel, oil & gas, bridge construction, shipbuilding, and high-rise development. As industry leaders grapple with rising costs and increasing project demands, understanding how to leverage advanced technology for enhanced productivity is paramount. Dave Graf serves as your dedicated resource for navigating these complexities, ensuring that your organization can harness the full potential of Akyapak’s innovations. Are you ready to confront the strategic challenge of maintaining competitive advantage in a rapidly evolving market? Discover how embracing advanced beam drilling solutions can unlock unprecedented efficiencies, reduce lead times, and ultimately drive profitability. Keep reading to explore the transformative opportunities that await your business.

If you’re looking to cut costs, boost efficiency, and get every possible advantage in today’s competitive metal fabrication market, then on-site nitrogen generation could be your game-changer. In this article, I share how my hands-on experience as a Sales Engineer at Mac-Tech enables fabricators to save thousands annually—often seeing a return on investment in under a year. From reducing costly gas deliveries to overcoming productivity bottlenecks, I’ll walk you through the process and show you why it’s a must-have solution for fabrication shops of all sizes. Ready to discover the hidden opportunities that could reshape your bottom line? Let’s dive in.

The Peddinghaus Ocean-Avenger-40, a 2016 model, offers a 60′ x 40″ beam capacity and single spindle precision, enhancing production efficiency and profitability. Contact Mac-Tech for more details: 888-MAC-9555.

Empowering sales teams with data-driven strategies fuels innovation and growth in metal fabrication. Let’s elevate your business! – Joe Ryan (joe@mac-tech.com, 414-477-8772)

I tailor Lissmac solutions for peak client satisfaction. Adam Quoss Vice President of Sales, Mac-Tech aquoss@mac-tech.com

John Perry, Regional Sales Executive at Mac-Tech, delves into the transformative power of tube lasers in welding and assembly processes. This article highlights how advanced laser technology can significantly enhance precision while reducing costs and lead times. With John’s consultative, solutions-driven approach, he leverages his deep industry knowledge to identify common challenges faced by manufacturers, such as labor inefficiencies and material waste. He presents tube lasers as a strategic solution that not only optimizes workflow but also elevates product quality. Decision-makers will find compelling insights that illustrate the potential for substantial efficiency gains and a competitive edge in the market. Read on to discover how embracing tube laser technology can redefine your operational landscape.

End of content

End of content