Mac-Tech has long stood as a trusted partner for fabrication shops seeking cutting-edge solutions that boost efficiency and profitability. Known for delivering innovative equipment and tailored support, Mac-Tech continually raises the standard for precision, reliability, and operational flexibility. The Wilson Tool lineup, particularly as featured in the 22 Wilson Tool Solutions, is a strategic addition for Iowa’s high-mix, low-volume fabrication shops. These advanced tools are engineered to resolve the unique challenges of dynamic production environments, helping fabricators maximize throughput, improve quality, and reduce operational headaches.

Maximize Productivity with Precision Punching Tools

The Wilson Tool punching systems are designed to deliver exceptional accuracy and speed, even in the most demanding fabrication settings. Engineered with state-of-the-art materials and advanced geometries, these tools provide consistent, burr-free holes across a wide range of materials and thicknesses. Shops handling frequent job changes and a diverse material mix benefit from the quick-change punch assemblies and precision-ground dies, which drastically cut setup times and minimize scrap.

Ideal for short runs and custom orders, the Wilson Tool punching solutions excel in environments where versatility is key. With features such as adjustable punch lengths and multi-tool stations, operators can switch from one part to another with minimal downtime. The result is a streamlined workflow that allows shops to take on more jobs without sacrificing quality or speed. Mac-Tech supports customers at every stage, from selecting the optimal punching solutions for their needs to providing expert installation and ongoing technical support.

Streamline Setup and Changeover with Modular Bending Solutions

High-mix, low-volume shops must often switch between different part geometries and material types. Wilson Tool’s modular bending solutions, such as quick-release tooling and universal dies, address this challenge by enabling rapid setup and changeover. These systems are engineered for compatibility with a wide array of press brakes, making them an ideal upgrade for shops aiming to boost agility and minimize downtime between jobs.

The modularity of these bending tools not only accelerates production but also reduces the potential for operator error. With color-coded components, ergonomic designs, and integrated safety features, these tools empower operators to achieve precise bends with every cycle. Mac-Tech’s team ensures a seamless transition, offering on-site setup, training, and process optimization to help shops unlock the full potential of their investment.

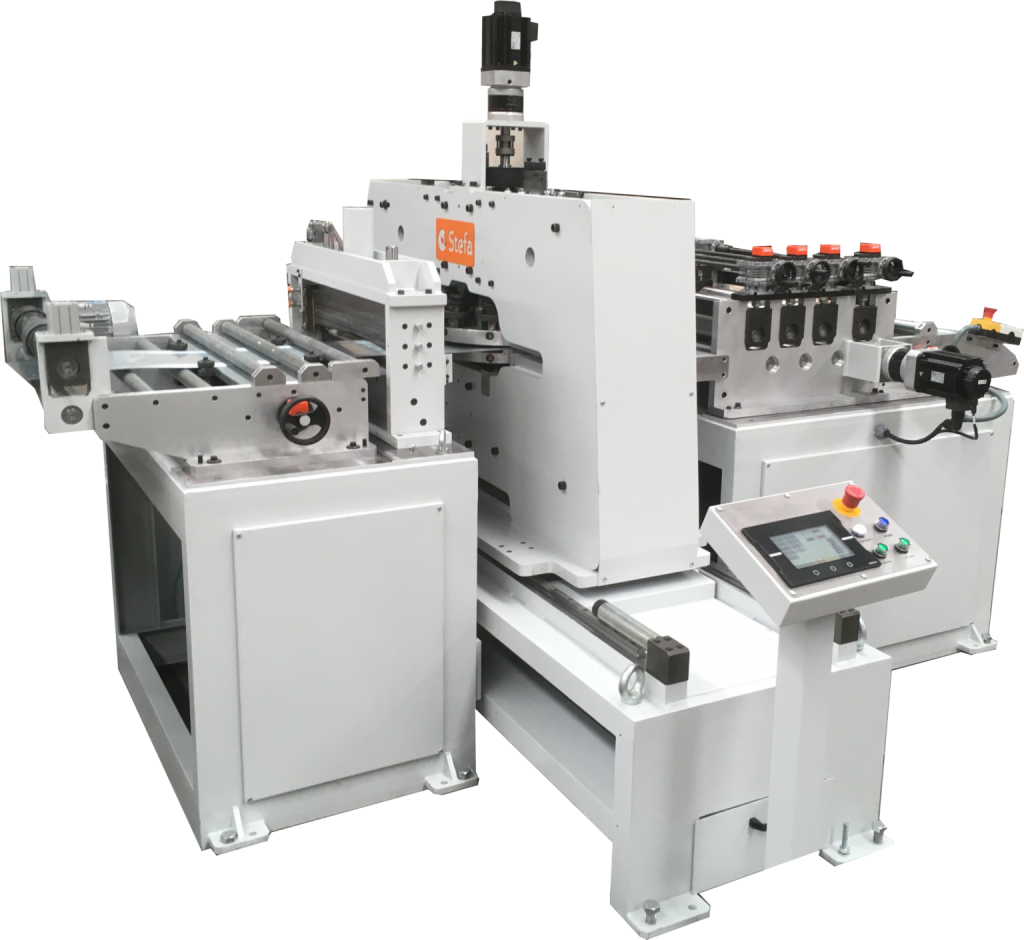

COIL PUNCHING

Achieve Consistent Quality in Low-Volume Runs with Advanced Tooling

Consistency is critical in low-volume production, where even minor deviations can lead to costly rework or rejected parts. The advanced tooling in the Wilson Tool lineup incorporates precision-ground surfaces and tight manufacturing tolerances to ensure repeatable results. Features such as self-centering punches, automatic die alignment, and integrated wear indicators help operators maintain top-tier quality across every batch.

These tools are specifically designed to handle the frequent changeovers and variable material demands of high-mix, low-volume work. The result is a significant reduction in setup errors and part variability, translating directly into greater customer satisfaction and a stronger reputation for quality. Mac-Tech provides ongoing technical support and access to application specialists who help customers maintain consistent output, even as job requirements evolve.

Reduce Downtime and Maintenance Costs with Durable Tool Designs

Durability is at the core of every Wilson Tool solution offered through Mac-Tech. Manufactured from premium tool steels and treated with advanced coatings, these tools are built to withstand the rigors of continuous use in demanding environments. Features such as replaceable wear components and simplified maintenance access further extend tool life and minimize unplanned downtime.

By reducing the frequency of tool replacement and maintenance interventions, shops can keep their lines running longer and reduce total cost of ownership. Mac-Tech’s service team is always ready to assist with preventive maintenance, troubleshooting, and rapid replacement parts, ensuring customers experience maximum uptime and productivity.

Enhance Flexibility for Custom Orders with Versatile Fabrication Solutions

Modern fabrication shops need to adapt quickly to changing customer demands, especially in the high-mix, low-volume segment. Wilson Tool’s versatile solutions—including multi-purpose punches, adjustable dies, and universal bending tools—make it easy to handle a wide variety of part profiles without the need for extensive retooling. This flexibility enables shops to accept more custom orders and expand their service offerings with confidence.

Whether fabricating prototypes or small production runs, shops benefit from tooling that reduces lead times and supports fast, accurate changeovers. Mac-Tech’s consultative approach ensures each customer receives the right combination of tools and accessories for their unique workflow, backed by expert guidance and responsive service.

Frequently Asked Questions

What types of materials can Wilson Tool solutions process effectively?

Wilson Tool solutions are engineered to handle a wide range of materials, including mild steel, stainless steel, aluminum, copper, and specialty alloys commonly used in fabrication shops.

How quickly can equipment be delivered and installed in Iowa?

Delivery and installation timelines vary based on equipment configuration and current demand, but most orders are fulfilled within two to four weeks. Mac-Tech coordinates all logistics and on-site setup to ensure a smooth transition.

Are these tools compatible with existing press brakes and punch presses?

Yes, Wilson Tool solutions are designed for broad compatibility with most major brands and models. Mac-Tech’s specialists can assess your current equipment and recommend compatible tooling options.

What maintenance is required to keep these tools performing at their best?

Routine inspection, cleaning, and lubrication are recommended. Many Wilson Tool products also feature replaceable wear parts and integrated indicators to simplify preventive maintenance.

Does Mac-Tech offer trade-in programs for outdated tooling or equipment?

Yes, trade-in options are available for qualifying equipment. This allows shops to upgrade to advanced tooling while offsetting investment costs.

What kind of post-sale support can customers expect?

Mac-Tech provides comprehensive post-sale support, including on-site training, troubleshooting, technical assistance, and rapid access to replacement parts.

Optional: For more info: 888-MAC-9555, or find Mac-Tech on LinkedIn.

Get Weekly Mac-Tech News & Updates