In today’s fast-paced manufacturing environment, the need for speed, precision, and efficiency is paramount. The GH High-Performance Fiber Laser Cutting Machine stands out as a game-changer in the industry, offering unparalleled performance and advanced features designed to meet the most demanding production requirements. This article delves into the key aspects of the GH Fiber Laser, highlighting its capabilities and how it can transform your manufacturing processes.

Introduction to GH High-Performance Fiber Laser

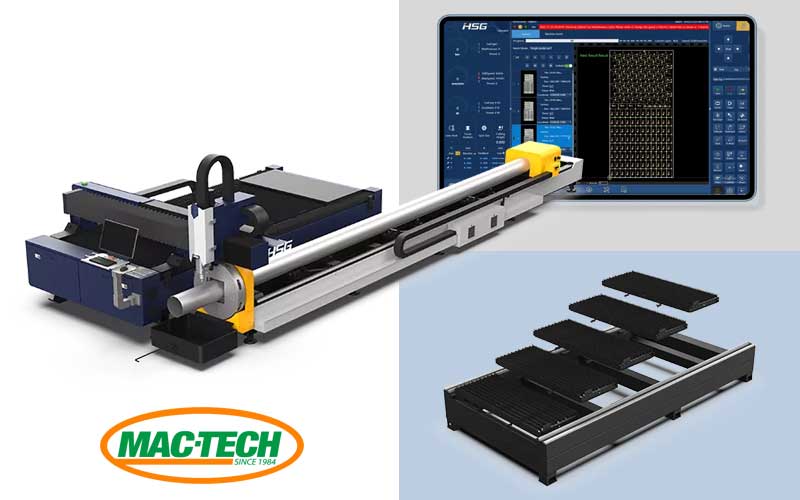

The GH High-Performance Fiber Laser Cutting Machine is engineered to deliver exceptional results in sheet processing. With its state-of-the-art technology and robust design, it caters to a wide range of industrial applications. Whether you are in automotive, aerospace, or general manufacturing, this machine offers the versatility and reliability you need to stay competitive.

One of the standout features of the GH Fiber Laser is its ability to handle complex cutting tasks with ease. The machine’s advanced fiber laser technology ensures clean, precise cuts, reducing the need for secondary processing. This not only saves time but also minimizes material waste, contributing to overall cost savings.

Moreover, the GH Fiber Laser is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels. This means you can quickly train your team and start reaping the benefits of this high-performance machine without a steep learning curve.

In addition to its cutting-edge technology, the GH Fiber Laser is built to last. Its durable construction and high-quality components ensure long-term reliability, making it a wise investment for any manufacturing operation.

Speed and Precision: Key Features of GH Fiber Laser

Speed and precision are at the core of the GH Fiber Laser’s design. The machine is capable of achieving a maximum speed of 200m/min, making it one of the fastest fiber lasers on the market. This high-speed capability allows you to complete large-scale projects in a fraction of the time it would take with traditional cutting methods.

Precision is equally important, and the GH Fiber Laser does not disappoint. Its advanced laser technology ensures that each cut is accurate to the finest detail. This level of precision is crucial for industries where even the smallest deviation can lead to significant issues down the line.

The machine’s high-speed and precision capabilities are complemented by its robust construction. The GH Fiber Laser is built to withstand the rigors of continuous operation, ensuring consistent performance over time. This reliability means you can count on the machine to deliver high-quality results, project after project.

Furthermore, the GH Fiber Laser’s precision is enhanced by its intelligent path optimization and vibration control features. These advanced technologies work together to minimize errors and ensure that each cut is executed flawlessly, further boosting your production efficiency.

Atlas Copco’s nitrogen generation systems

HSG CB Series

Sheet & Tube Cutting in One Machine

Compact. Capable. Cost-Saving.

When you need maximum performance with minimal footprint, the HSG CB Series…

Achieving Maximum Speed and Acceleration

Achieving maximum speed and acceleration is a hallmark of the GH Fiber Laser. With an acceleration rate of up to 4.0G, this machine can quickly ramp up to its top speed, significantly reducing cycle times. This rapid acceleration is particularly beneficial for high-volume production environments where time is of the essence.

The GH Fiber Laser’s impressive speed and acceleration are made possible by its high-performance components. The machine is equipped with professional-grade speed reducers, high-precision racks, and guide rails, all of which contribute to its exceptional dynamic performance. These components ensure smooth and stable operation, even at high speeds.

In addition to its high-speed capabilities, the GH Fiber Laser also offers excellent control. The machine’s advanced control system allows for precise adjustments, ensuring that each cut is executed with the utmost accuracy. This level of control is essential for maintaining quality and consistency in your production processes.

Moreover, the GH Fiber Laser’s speed and acceleration capabilities are designed to enhance overall efficiency. By reducing cycle times and increasing throughput, this machine helps you meet tight deadlines and improve your bottom line. Whether you are producing small batches or large volumes, the GH Fiber Laser delivers the performance you need to stay ahead of the competition.

HSG Laser Bus Control System: Intuitive and Eco-Friendly

The HSG Laser Bus Control System is a key feature of the GH Fiber Laser, offering robust and versatile functions that enhance the user experience. This upgraded control system provides an intuitive interface that simplifies operation, making it easy for operators to manage the machine’s various functions.

One of the standout features of the HSG Laser Bus Control System is its eco-friendly design. The system is engineered to minimize energy consumption, reducing your overall operating costs and environmental impact. This makes the GH Fiber Laser not only a high-performance machine but also a sustainable choice for your manufacturing needs.

The control system also offers advanced diagnostic and monitoring capabilities. These features allow you to keep track of the machine’s performance in real-time, identifying potential issues before they become major problems. This proactive approach to maintenance helps ensure the long-term reliability of the GH Fiber Laser.

In addition to its intuitive and eco-friendly design, the HSG Laser Bus Control System is highly customizable. You can tailor the system’s settings to meet your specific production requirements, ensuring optimal performance for your unique applications. This level of customization further enhances the machine’s versatility and value.

Intelligent Path Optimization and Vibration Control

Intelligent path optimization is a critical feature of the GH Fiber Laser, designed to enhance cutting efficiency and accuracy. The machine’s advanced algorithm calculates the most efficient cutting path, minimizing travel time and reducing material waste. This optimization not only speeds up the cutting process but also improves overall productivity.

Vibration control is another important aspect of the GH Fiber Laser’s design. The machine is equipped with smart vibration control technology that minimizes the impact of vibrations on cutting accuracy. This ensures that each cut is executed with precision, even at high speeds, resulting in cleaner edges and fewer defects.

The combination of intelligent path optimization and vibration control makes the GH Fiber Laser an ideal choice for complex cutting tasks. Whether you are working with intricate designs or large-scale projects, these features help ensure that each cut is executed flawlessly, reducing the need for rework and improving overall efficiency.

Moreover, the GH Fiber Laser’s intelligent path optimization and vibration control features are designed to work seamlessly with its other advanced technologies. This integrated approach ensures that the machine delivers consistent, high-quality results, project after project. By leveraging these advanced features, you can achieve greater efficiency and accuracy in your manufacturing processes.

Advanced Heat Protection for Enhanced Safety

Heat protection is a critical consideration in any laser cutting operation, and the GH Fiber Laser excels in this area. The machine is equipped with advanced heat protection features that safeguard both the equipment and the material being processed. This ensures that you can achieve high-quality cuts without the risk of heat damage.

One of the key components of the GH Fiber Laser’s heat protection system is its high-density burn-resistant plates. These plates are designed to withstand extreme temperatures, protecting the machine bed from heat damage. This not only extends the lifespan of the equipment but also ensures consistent performance over time.

In addition to its burn-resistant plates, the GH Fiber Laser also features air pressure DA correction and torque protection for dual drives. These advanced technologies help regulate the machine’s temperature, preventing overheating and ensuring stable operation. This level of heat protection is essential for maintaining the quality and integrity of your cuts.

The GH Fiber Laser’s heat protection features are designed to work seamlessly with its other advanced technologies. This integrated approach ensures that the machine delivers consistent, high-quality results, even under demanding conditions. By prioritizing heat protection, the GH Fiber Laser helps you achieve safer, more reliable cutting operations.

High-Precision Transmission System Components

The GH Fiber Laser’s high-precision transmission system is a key factor in its exceptional performance. The machine is equipped with professional-grade speed reducers, high-precision racks, and guide rails, all of which contribute to its smooth and stable operation. These components are designed to withstand the rigors of continuous use, ensuring long-term reliability.

The high-precision transmission system is essential for achieving accurate cuts. The machine’s advanced components work together to minimize deviations and ensure that each cut is executed with the utmost precision. This level of accuracy is crucial for industries where even the smallest error can lead to significant issues.

In addition to its high-precision components, the GH Fiber Laser also features an upgraded matrix machine bed with enhanced rigidity. This innovative design significantly increases the rigidity of the entire machine bed structure, reducing any negative impacts on performance. This ensures that the machine delivers consistent, high-quality results, project after project.

The GH Fiber Laser’s high-precision transmission system is designed to work seamlessly with its other advanced technologies. This integrated approach ensures that the machine delivers consistent, high-quality results, even under demanding conditions. By prioritizing precision and reliability, the GH Fiber Laser helps you achieve greater efficiency and accuracy in your manufacturing processes.

Upgraded Matrix Machine Bed for Increased Rigidity

The GH Fiber Laser’s upgraded matrix machine bed is a standout feature that enhances the machine’s overall performance. This innovative design significantly increases the rigidity of the entire machine bed structure, reducing any negative impacts on performance. This ensures that the machine delivers consistent, high-quality results, project after project.

The matrix machine bed is constructed using advanced welding techniques that enhance its strength and durability. This robust construction ensures that the machine can withstand the rigors of continuous use, providing long-term reliability and consistent performance. This makes the GH Fiber Laser a wise investment for any manufacturing operation.

In addition to its enhanced rigidity, the matrix machine bed also features a brand-new aluminum beam. This fifth-generation 6-series aluminum beam is 20% lighter and offers 15% more torsional resistance than previous models. This lightweight design enhances the equipment’s dynamic performance, boosting processing efficiency.

The GH Fiber Laser’s upgraded matrix machine bed is designed to work seamlessly with its other advanced technologies. This integrated approach ensures that the machine delivers consistent, high-quality results, even under demanding conditions. By prioritizing rigidity and durability, the GH Fiber Laser helps you achieve greater efficiency and accuracy in your manufacturing processes.

FAQ

What industries can benefit from the GH High-Performance Fiber Laser?

The GH Fiber Laser is versatile and can be used in various industries, including automotive, aerospace, and general manufacturing.

How does the GH Fiber Laser achieve such high speeds?

The machine’s high-speed capabilities are made possible by its professional-grade speed reducers, high-precision racks, and guide rails, which ensure smooth and stable operation.

Is the GH Fiber Laser easy to operate?

Yes, the machine features an intuitive interface and easy-to-use controls, making it accessible to operators of all skill levels.

What kind of heat protection does the GH Fiber Laser offer?

The machine is equipped with high-density burn-resistant plates, air pressure DA correction, and torque protection for dual drives, ensuring advanced heat protection.

Can the GH Fiber Laser handle complex cutting tasks?

Absolutely. The machine’s intelligent path optimization and vibration control features make it ideal for complex cutting tasks, ensuring precise and accurate cuts.

How does the HSG Laser Bus Control System enhance the user experience?

The control system offers an intuitive interface, advanced diagnostic and monitoring capabilities, and eco-friendly design, making it easy to operate and maintain.

What makes the GH Fiber Laser a reliable investment?

The machine’s durable construction, high-quality components, and advanced technologies ensure long-term reliability and consistent performance, making it a wise investment for any manufacturing operation.

The GH High-Performance Fiber Laser Cutting Machine is a powerful tool that can transform your manufacturing processes. With its advanced features and robust design, it offers the speed, precision, and efficiency you need to stay competitive. If you’re looking to optimize your production process or need expert advice on metal fabrication equipment, I’m here to help. Feel free to reach out to discuss your needs.

Get Weekly Mac-Tech News & Updates