Sheet Lasers vs. Plate Lasers: Maximizing ROI with Power and Beam Quality for Fabrication Shops

John Perry guides buyers to boost efficiency and profits by choosing the ideal laser or press brake system tailored to their shop’s unique needs.

John Perry guides buyers to boost efficiency and profits by choosing the ideal laser or press brake system tailored to their shop’s unique needs.

Prodevco’s systems boost Illinois fabrication with precise beam drilling, faster coping, and lower costs, solving key production challenges. Contact Mac-Tech: 888-MAC-9555

Kyle Bialozynski leverages field experience to deliver smart, customer-focused beam coping solutions with Prodevco Robotics for ROI-driven fabrication growth. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

Nicole Salato shares 4 key tips to keep your Prodevco Beam Coping System running smoothly with proactive service & parts. Stay ahead—contact Nicole! Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

Illinois steel fabricators turn to Prodevco beam lines for enhanced precision, faster workflows, and lower production costs. Contact Mac-Tech: 888-MAC-9555

Patrick (Pat) O’Neill, National Product Manager and Regional Sales Executive at Mac-Tech, discusses how combi-beam folders offer manufacturers increased efficiency and versatility for multi-profile forming. Drawing on his expertise, Pat explains how integrating advanced folding, roll forming, and coil-fed fabrication systems can help customers streamline production, reduce material handling, and achieve greater flexibility in their operations. He works closely with clients to identify solutions that optimize workflow and enhance overall productivity. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929

Illinois beam shops are streamlining production, cutting costs, and improving accuracy by switching from manual coping to Prodevco automated systems. Contact Mac-Tech: 888-MAC-9555

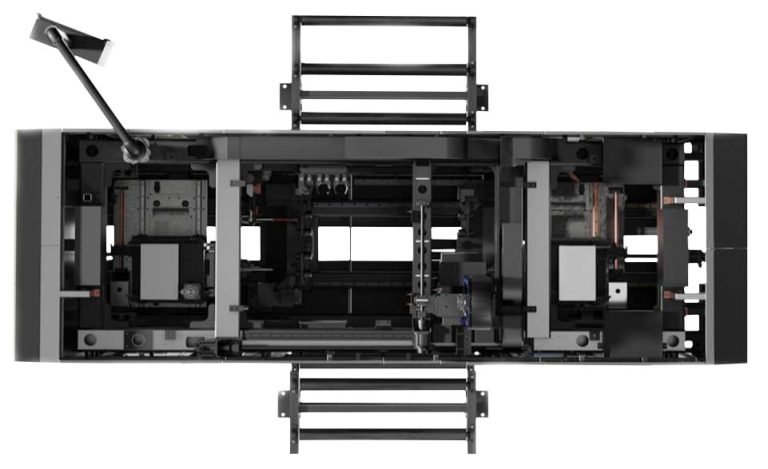

Dave Graf, Regional Sales Executive at Mac-Tech, explores how unified beam drilling and coping automation boosts ROI for structural steel fabricators in sectors like oil & gas, shipbuilding, and construction. As the go-to expert, Dave offers streamlined, comprehensive automation solutions tailored to industry needs.

Dave Graf, Regional Sales Executive at Mac-Tech, explores how Prodevco Beam Coping optimizes ROI in structural steel fabrication for industries like oil & gas, shipbuilding, and construction. As the go-to expert, Dave provides comprehensive automation solutions tailored to enhance efficiency and precision.

End of content

End of content