-

Coil-to-Part Line Planning for Predictable Throughput ROI

Pat O’Neill explains how disciplined coil-to-part line planning turns throughput goals into predictable ROI. By selecting the right forming method and coil-fed system layout, manufacturers can stabilize feed and forming conditions, improve part accuracy, and reduce scrap from camber, twist, and setup variation. Proper matching of decoilers, straighteners, servos, and press or roll-form tooling boosts…

-

Legacy CNC Modernization: Scope, Train, Phase Cutover

Legacy CNC modernization made practical: scope upgrades, train teams, phase cutover to cut risk, boost uptime and ROI in fabrication.

-

Turnkey Multi-Machine Automation Scoping for Heavy Fabrication ROI

Dave Graf outlines how turnkey, multi-machine automation scoping helps heavy fabricators plan and justify end-to-end upgrades that improve throughput, consistency, and labor efficiency. The approach maps current workflows, selects complementary machines and software, and defines material handling and integration requirements to reduce risk during installation. By modeling payback and total cost of ownership, the process…

-

Go Live Uptime Readiness for Service and Parts

Nicole Salato guides shops to boost uptime by preventing breakdowns, replacing worn parts proactively, and planning reliable maintenance for go-live readiness. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

-

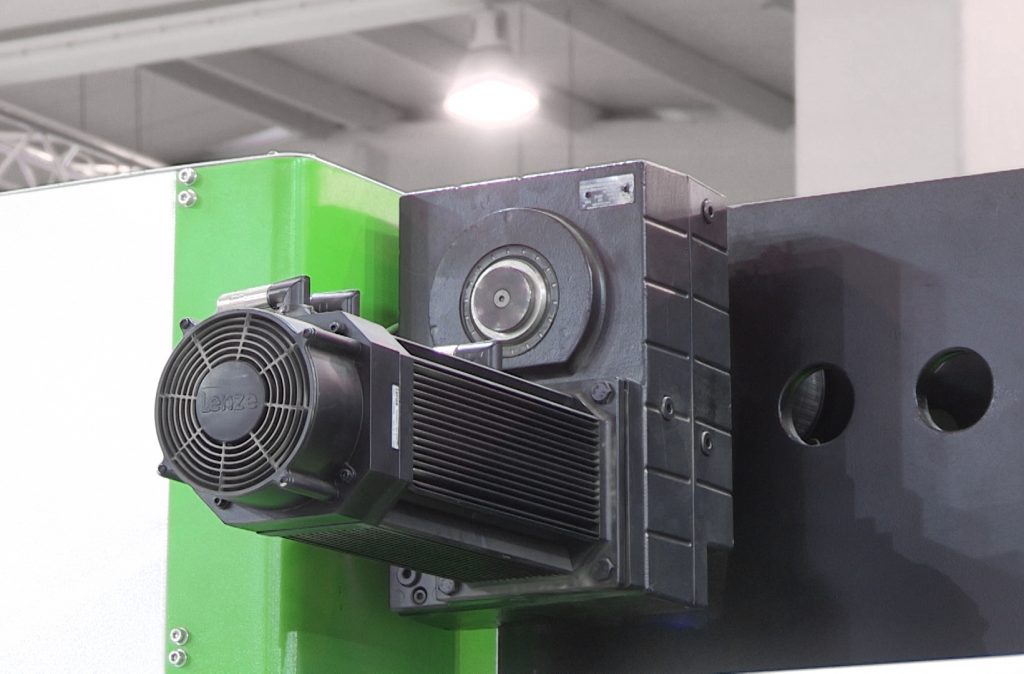

Ermaksan Tandem Brakes Enhance Shipbuilding Efficiency

Dave Graf, Regional Sales Executive at Mac-Tech, discusses how Ermaksan tandem brakes enhance efficiency in the shipbuilding industry. He highlights their role in providing end-to-end automation solutions for structural steel fabrication across the oil & gas, shipbuilding, bridge, and tower construction sectors. These solutions streamline production processes, reduce labor costs, and improve precision, making them…

-

Hydmech Saws and Lasers: Revolutionizing Illinois Fabrication Shops

Hydmech’s automated saws and lasers enhance Illinois fabrication by solving production issues, boosting accuracy, and cutting costs in multi-process facilities. Contact Mac-Tech: 888-MAC-9555

-

Adaptive Tooling Elevates Flexibility in Panel Bending

The article by Patrick (Pat) O’Neill discusses how adaptive tooling enhances flexibility in panel bending, focusing on improving production efficiency, forming accuracy, and line reliability. Pat emphasizes the importance of selecting the right machines, integrating automation, and implementing practical planning strategies. These measures help manufacturers optimize their operations and adapt to changing demands. By leveraging…

-

Ermaksan’s High-Tonnage Bending: Boosting Construction and Shipbuilding Efficiency

The article by John Perry, Regional Sales Executive at Mac-Tech, discusses how Ermaksan’s high-tonnage bending solutions enhance efficiency in construction and shipbuilding. It highlights the importance of making informed, ROI-driven decisions regarding lasers, press brakes, and automation systems. John emphasizes the benefits of these technologies in improving productivity and reducing operational costs for manufacturers. John…