-

Critical Spares Stocking for Reliability Amid Lead Time Uncertainty

Nicole Salato guides shops to stock critical spares to avert breakdowns, replace worn parts fast, and plan maintenance that stays reliable amid lead-time uncertainty. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

-

Executive Checklist for Uptime, Integration, Training, Commissioning Risk Controls

Dave Graf outlines an executive checklist to maximize uptime and ROI when adopting end-to-end automation in structural steel fabrication. The article highlights planning for seamless integration across layout, cutting, drilling, welding, and material handling, along with commissioning risk controls to reduce disruption. It emphasizes operator training, standardized workflows, and data connectivity to accelerate ramp-up, improve…

-

Laser-to-Brake CAD/CAM Sync Cuts Rework First-Time Fit

Learn how laser-to-brake CAD/CAM sync cuts rework, boosts first-time fit, and delivers faster throughput, fewer scrap costs, and ROI.

-

HSG Fiber Laser Package Handling Gas Cooling Consumables for Uptime

Fiber laser packages cut accurately with gas, cooling, and consumables control, reducing handling, stabilizing quality, and lowering cost per part. Contact Mac-Tech: 888-MAC-9555

-

Real-World ROI Model for Coil Automation Payback

Pat O’Neill outlines a practical ROI model for evaluating coil automation payback, emphasizing data-driven choices in forming equipment and coil-fed line configuration. The approach ties capital decisions to measurable gains in throughput, tighter forming accuracy, and lower scrap through consistent material handling and process control. It also highlights how improved line reliability and reduced downtime…

-

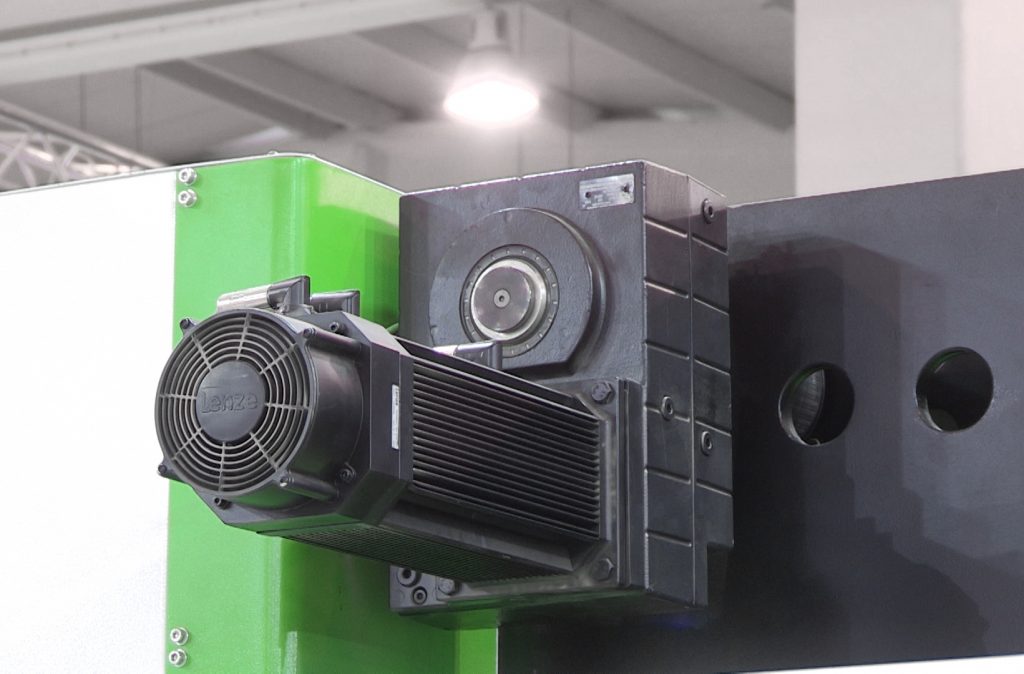

Preventive Maintenance Systems Reduce Laser and Press Brake Downtime

Nicole Salato guides shops to cut laser and press brake downtime by spotting wear early, replacing components, and scheduling maintenance before failures. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

-

Procurement to Production Governance for On-Time Spec Delivery

Dave Graf outlines how procurement-to-production governance helps structural steel fabricators deliver on spec and on time in oil & gas, shipbuilding, bridge, and tower projects. The article emphasizes planning end-to-end automation around real workflows, integrating estimating, purchasing, material tracking, scheduling, and machine control to reduce rework and delays. By standardizing data and accountability from order…

-

Ramp-Up Training Plan: Pilot Group, Validation Parts, Proven ROI

Kyle Bialozynski shares field-tested, customer-first ramp-up training and validation parts guidance to speed adoption and ROI for fabrication upgrades. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

-

Fabrication Cell Planning IL IA Cutting Bending Handling Support Flow

Shows IL/IA fabs how integrated cutting, bending, handling, and support cells boost accuracy, cut handling, and lower cost/part. Contact Mac-Tech: 888-MAC-9555