-

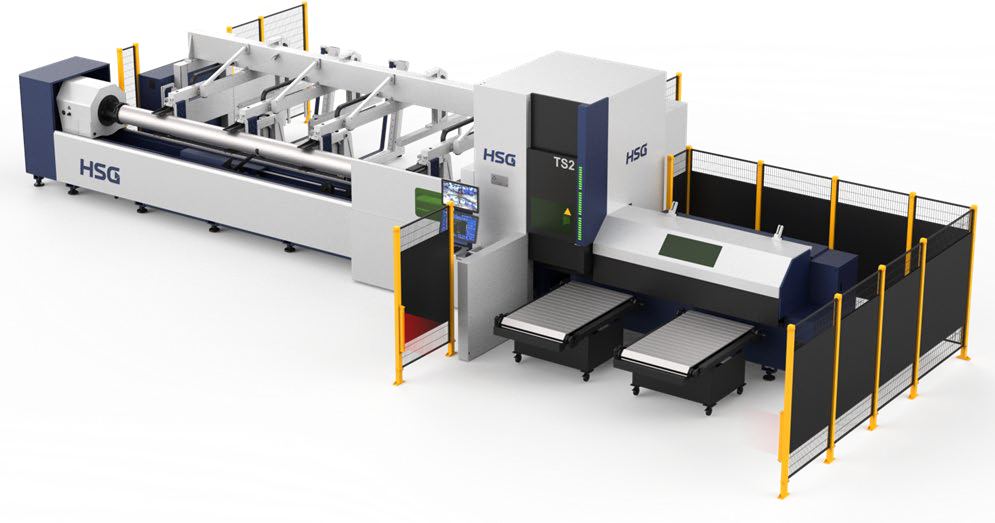

Wisconsin Fabricators Choose HSG Fiber Lasers over Plasma and CO2 for Faster Throughput, Less Rework, and ROI-Driven Growth

With field experience, Kyle Bialozynski shows WI fabricators choosing HSG fiber lasers for speed, less rework, ROI—smart, customer-first fabrication solutions. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

-

How I Help Shops Reduce Downtime Through Scheduled Maintenance

Nicole Salato keeps shops ahead of breakdowns with scheduled maintenance, proactive service, and fast parts sourcing to cut downtime and costs. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

-

End-to-End Structural Processing Saw Prep Drilling Coping Handling IL IA

End-to-end equipment streamlines saw prep, drilling, coping, and handling to cut touch time, boost accuracy, and lower cost per part. Contact Mac-Tech: 888-MAC-9555

-

Cut Form Coordination Cuts WIP, Prevents Late Coil Jobs

Pat O’Neill explains how coordinating cut length with forming operations reduces work-in-process and prevents late coil-fed jobs. By aligning tooling setup, cut sequencing, and downstream handling, manufacturers can improve throughput while maintaining tighter forming accuracy. Better decisions in coil-fed system selection, automation, and control integration minimize changeover errors, stabilize line performance, and reduce scrap from…

-

Press Brake Throughput System Tooling Quick-Change Changeover Standard Work

Tooling plus quick-change clamping and standard work cut press brake changeovers, boost accuracy, reduce handling, and lower cost per part. Contact Mac-Tech: 888-MAC-9555

-

Panel Bender Folder Integration Beats Added Press Brake ROI

Pat O’Neill explains that integrating a panel bender with a folder in a coil-fed line can outperform adding another press brake by boosting throughput and maintaining consistent flow. The approach improves forming accuracy through controlled, repeatable bends, reducing rework and scrap caused by variation and handling. Right-sizing forming technology to the part mix and pairing…

-

ROI Model: Retrofit vs Replace Without Payback Guessing

Stop guessing payback. Use a clear ROI model to compare retrofitting vs replacing equipment, modernize smarter, and justify capex with confidence.

-

Small-Team Automation ROI Load Unload Towers for Winter Uptime

Kyle shares field-tested, customer-first guidance on load/unload tower automation ROI and practical fabrication upgrades to keep small teams running all winter. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

-

Critical Spares Stocking for Reliability Amid Lead Time Uncertainty

Nicole Salato guides shops to stock critical spares to avert breakdowns, replace worn parts fast, and plan maintenance that stays reliable amid lead-time uncertainty. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com