As a Regional Sales Executive at Mac-Tech, I’ve spent years working closely with clients to help them navigate the complexities of selecting the right machinery for their operations. One of the most common questions I get is about choosing the best brand of used hydraulic press brakes. It’s a decision that can significantly impact productivity and efficiency, and I take pride in guiding my clients through this process. My approach is consultative, and I focus on understanding each client’s unique needs and goals. With expertise in flat and tube lasers, beam line robotic coping, press brakes, and tube bending, I aim to provide tailored solutions that enhance operational efficiency and profitability.

Understanding Your Press Brake Needs and Goals

When I first meet with a client, my priority is to understand their specific needs and goals. Every business is different, and what works for one might not work for another. I ask questions about their current processes, production volumes, and future expansion plans. This helps me identify the most suitable press brake options that align with their objectives. It’s not just about selling a machine; it’s about ensuring that the equipment will truly add value to their operations.

I also consider the types of materials my clients work with and the precision required in their projects. This technical insight allows me to recommend machines that can handle their workload efficiently. By understanding these details, I can suggest brands and models that have a proven track record in similar applications. My goal is to match them with a press brake that enhances their capabilities and meets their production demands.

Moreover, I emphasize the importance of scalability. Businesses grow, and their needs evolve. I help my clients think ahead, ensuring that the press brake they choose today can adapt to their future requirements. This forward-thinking approach ensures long-term satisfaction and maximizes their investment.

Evaluating Brand Reputation and Reliability

In the world of used hydraulic press brakes, brand reputation and reliability are paramount. Over the years, I’ve developed a keen understanding of which brands consistently deliver quality and durability. I rely on my experience and industry knowledge to guide clients toward brands with a solid reputation for performance and longevity.

I often recommend brands that have a strong presence in the market and are known for their robust engineering and customer support. These are the brands that have stood the test of time and continue to innovate. I share insights from my experiences and those of other clients to highlight why certain brands are preferred over others.

Reliability is a key factor in minimizing downtime and maintenance costs. I ensure that the brands I recommend have a track record of reliability and low failure rates. This not only boosts productivity but also provides peace of mind to my clients, knowing they have invested in a dependable machine.

Prioritizing Customer Satisfaction and Support

Customer satisfaction is at the heart of what I do. I believe that the relationship with a client doesn’t end after the sale; it’s just the beginning. I prioritize brands that offer excellent customer support and service. This ensures that my clients have access to technical assistance and spare parts whenever needed.

I work closely with clients to ensure they are comfortable with their new equipment. This includes providing training and support to help them get the most out of their press brake. I also stay in touch to address any questions or concerns that may arise, reinforcing the trust and reliability they expect from Mac-Tech.

Furthermore, I encourage clients to share their feedback and experiences with the brands I recommend. This not only helps me refine my recommendations but also builds a community of satisfied customers who can vouch for the quality and performance of their press brakes.

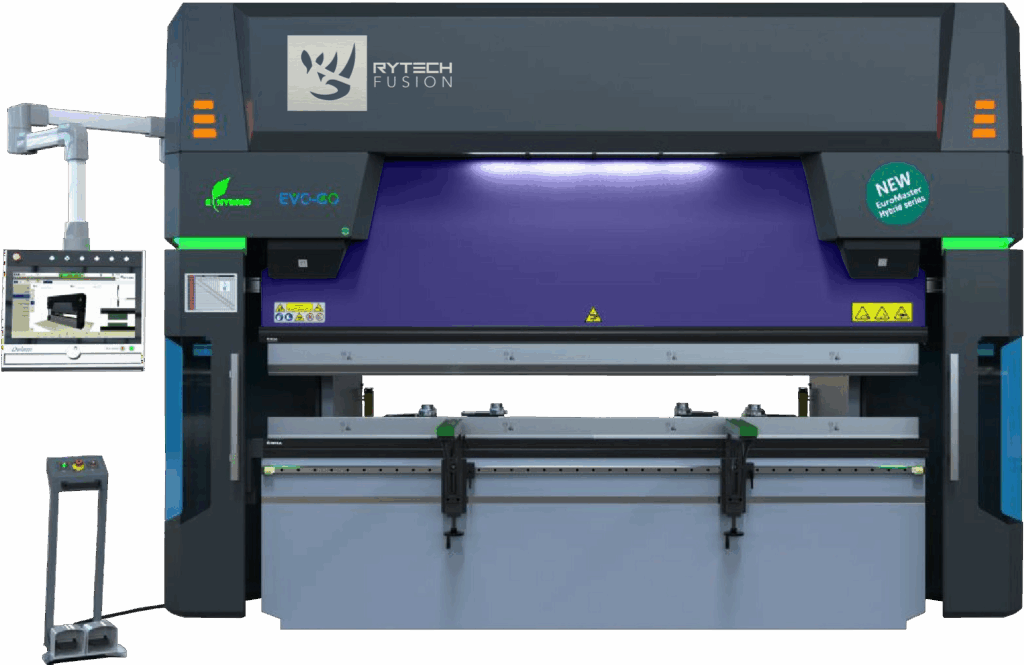

RYTECH FUSION Hybrid Performance Press Brake

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

RYTECH CORE+ PRECISION HYDRAULIC PRESS BRAKE

Precision. Performance. Innovation.

The RYTECH CORE+ delivers elite bending performance with modular automation compatibility, premium hybrid servo systems, and advanced control — backed by…

Comparing Key Features and Performance Metrics

Not all press brakes are created equal, and understanding the key features and performance metrics is crucial in making the right choice. I guide my clients through the technical specifications, explaining the importance of factors like tonnage, bending length, and control systems. This knowledge empowers them to make informed decisions.

I also highlight the technological advancements in newer models, such as CNC controls and energy-efficient systems. These features can significantly enhance productivity and reduce operational costs. By comparing these metrics across different brands, I help clients identify the best fit for their specific needs.

Performance metrics are not just about numbers; they translate into real-world benefits. I share case studies and examples where clients have achieved remarkable improvements in efficiency and output by selecting the right press brake. This practical insight helps clients visualize the potential impact on their own operations.

Highlighting Cost-Effectiveness and Value

Cost is always a consideration, but it’s important to focus on value rather than just price. I help clients evaluate the total cost of ownership, including maintenance, energy consumption, and potential downtime. This holistic approach ensures they get the best return on their investment.

I emphasize the long-term benefits of choosing a quality used press brake over a cheaper, less reliable option. A well-maintained machine from a reputable brand can offer years of reliable service, making it a cost-effective choice in the long run. I provide detailed comparisons to illustrate these points.

Additionally, I assist clients in exploring financing options and incentives that can make their purchase more affordable. By understanding their budget constraints and financial goals, I can recommend solutions that align with their financial strategy while still delivering the performance they need.

Sharing Success Stories and Customer Feedback

One of the most rewarding parts of my job is hearing success stories from clients who have benefited from my recommendations. These stories serve as a testament to the value of choosing the right press brake. I share these experiences to inspire confidence and illustrate the tangible benefits of my consultative approach.

For instance, a client in the automotive industry was able to double their production capacity by upgrading to a used press brake I recommended. This not only improved their efficiency but also opened up new business opportunities. Such stories reinforce the importance of making informed decisions based on expert guidance.

I also encourage clients to share their feedback and experiences, which helps me continuously improve my service. This feedback loop ensures that I stay updated on industry trends and client needs, allowing me to provide even better recommendations in the future.

FAQ Section

What should I consider when choosing a used hydraulic press brake?

Consider factors like your production needs, material types, brand reputation, reliability, and total cost of ownership. It’s important to align these with your long-term business goals.

How do I know if a brand is reliable?

Look for brands with a strong market presence and positive customer reviews. I can also provide insights based on my experience and feedback from other clients.

What if I have a limited budget?

There are financing options and incentives available that can make purchasing a quality used press brake more affordable. I can help explore these options to find a solution that fits your budget.

How important is customer support for used equipment?

Customer support is crucial for maintaining your equipment and minimizing downtime. I prioritize brands that offer excellent support to ensure you have access to the necessary resources.

Can a used press brake be as effective as a new one?

Yes, a well-maintained used press brake from a reputable brand can be just as effective as a new one, offering significant cost savings without compromising performance.

What are the benefits of advanced features like CNC controls?

CNC controls enhance precision, reduce setup time, and improve overall efficiency, making them a valuable feature for many operations.

How can I ensure my press brake purchase is future-proof?

Consider scalability and flexibility in your choice. I can help you select a machine that not only meets your current needs but can also adapt to future demands.

If you’re looking to optimize your production process with a reliable used hydraulic press brake, I’m here to help. Let’s discuss your needs and find the perfect solution for your business.

Get Weekly Mac-Tech News & Updates