In the world of metal fabrication, the press brake is a cornerstone machine, essential for bending and shaping metal with precision. However, like any sophisticated piece of equipment, its performance is heavily reliant on the software that drives it. Keeping your press brake software updated and well-maintained is crucial for optimizing operations, ensuring accuracy, and extending the lifespan of your machine. This article delves into the importance of updated software for press brake operations, the key benefits of maintaining it, and the steps you can take to ensure your software is always current.

Importance of Updated Software for Press Brake Operations

In the fast-paced environment of metal fabrication, the efficiency and accuracy of your press brake can significantly impact your productivity and bottom line. Updated software plays a pivotal role in this equation. Modern software updates often include enhancements that improve the machine’s performance, offering new features that streamline operations and reduce the likelihood of errors. These updates can also address bugs and vulnerabilities that, if left unchecked, could lead to costly downtime or even damage to the machine.

Moreover, updated software ensures compatibility with the latest industry standards and technologies. As the metal fabrication industry evolves, so do the materials and techniques used. Updated software can provide the necessary tools and functionalities to handle new materials and complex bending requirements, keeping your operations competitive and efficient. Without these updates, your press brake may struggle to meet the demands of modern fabrication tasks, leading to inefficiencies and potential loss of business.

Finally, updated software enhances the safety of press brake operations. Safety protocols and features are continually being improved and integrated into software updates. By keeping your software current, you ensure that your machine is equipped with the latest safety measures, protecting your operators and reducing the risk of accidents. In an industry where precision and safety are paramount, neglecting software updates can have serious repercussions.

Key Benefits of Maintaining Press Brake Software

Maintaining your press brake software offers numerous benefits that extend beyond mere operational efficiency. One of the primary advantages is improved accuracy. Updated software often includes advanced algorithms and calibration tools that enhance the precision of bends, reducing material waste and ensuring consistent quality in your products. This level of accuracy is essential for meeting stringent industry standards and customer expectations.

Another significant benefit is increased machine lifespan. Regular software updates can optimize the performance of your press brake, reducing wear and tear on mechanical components. By addressing potential issues before they escalate, you can prevent costly repairs and extend the operational life of your machine. This proactive approach to maintenance not only protects your investment but also ensures that your press brake remains a reliable asset in your production line.

Additionally, maintaining your press brake software can lead to cost savings. Updated software can improve the efficiency of your operations, reducing cycle times and energy consumption. It can also minimize downtime by preventing software-related issues that could halt production. These efficiencies translate into lower operational costs and higher profitability. In a competitive market, the ability to operate more efficiently and cost-effectively can give your business a significant edge.

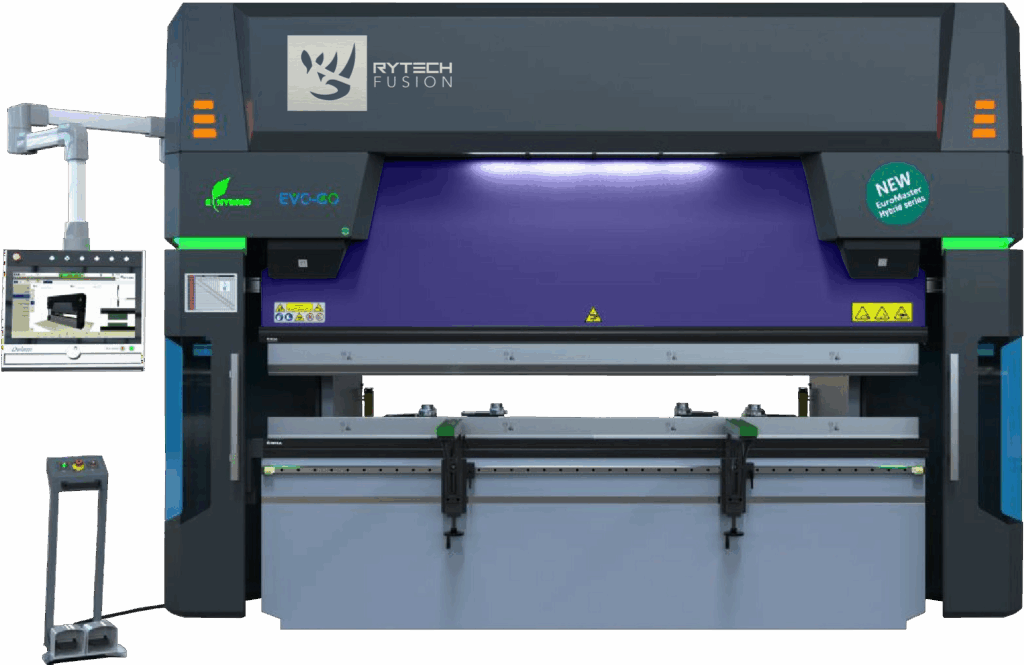

RYTECH FUSION Hybrid Performance Press Brake

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

RYTECH CORE+ PRECISION HYDRAULIC PRESS BRAKE

Precision. Performance. Innovation.

The RYTECH CORE+ delivers elite bending performance with modular automation compatibility, premium hybrid servo systems, and advanced control — backed by…

Steps to Ensure Your Press Brake Software is Current

Ensuring that your press brake software is always current involves a few straightforward but essential steps. First, establish a regular update schedule. Just as you would schedule routine maintenance for the mechanical components of your press brake, set aside time to check for and install software updates. Many manufacturers provide notifications or alerts when updates are available, making it easier to stay on top of this task.

Second, work closely with your software provider or machine manufacturer. They can offer valuable insights and support to ensure that your software is up-to-date and functioning optimally. Regular communication with these experts can also help you stay informed about new features and improvements that could benefit your operations. Additionally, consider enrolling in a maintenance program that includes software updates as part of the service package.

Finally, invest in training for your operators and maintenance staff. Updated software often comes with new features and functionalities that can enhance your press brake operations. However, to fully leverage these improvements, your team needs to be proficient in using the updated software. Regular training sessions can ensure that your staff is knowledgeable about the latest updates and can utilize them effectively, maximizing the benefits of your investment.

FAQ

Why is it important to keep press brake software updated?

Keeping press brake software updated ensures optimal machine performance, enhances accuracy, improves safety, and extends the lifespan of the equipment.

How often should I update my press brake software?

It’s advisable to check for updates regularly, at least once a quarter, and install them as soon as they become available to ensure continuous optimal performance.

Can outdated software affect the safety of press brake operations?

Yes, outdated software may lack the latest safety features and protocols, increasing the risk of accidents and compromising operator safety.

What are the signs that my press brake software needs an update?

Signs include decreased machine performance, frequent errors, compatibility issues with new materials, and notifications from the manufacturer about available updates.

How can I ensure my team is proficient with updated software?

Regular training sessions and workshops can help your team stay proficient with the latest software updates and functionalities.

Is it expensive to maintain press brake software?

While there may be costs associated with updates and training, the long-term benefits of improved efficiency, accuracy, and reduced downtime often outweigh these expenses.

Can I update the software myself, or do I need professional help?

While some updates can be performed in-house, it’s often beneficial to seek professional help to ensure the updates are installed correctly and to take full advantage of new features.

Keeping your press brake software updated is a critical aspect of maintaining optimal operations and protecting your investment. By following the steps outlined above and understanding the benefits of regular software maintenance, you can ensure that your press brake remains a reliable and efficient part of your production line. If you have any questions or need assistance with your press brake software, feel free to reach out.

Get Weekly Mac-Tech News & Updates