Evaluating Indiana Manufacturers for Metal Roofing: Key Machinery and Process Insights from Pat O’Neill

As National Sales Executive at Mac-Tech, I have had the privilege of working closely with metal roofing manufacturers across Indiana, helping them optimize their production lines with advanced machinery. In my experience, the foundation of a successful manufacturing operation lies in selecting the right equipment and processes that align with product requirements and efficiency goals. Evaluating Indiana manufacturers requires a keen understanding of the specific challenges faced in metal roofing and downspout production, especially when it comes to cutting, folding, and forming metal components. Asking the right questions during a shop evaluation can reveal critical insights into how well a manufacturer’s setup supports quality, throughput, and flexibility.

One of the key elements I focus on when assessing manufacturers is their capability to maintain precision and consistency in metal forming operations. Machines that are outdated or poorly maintained can lead to defects, downtime, and wasted materials. It’s essential to inquire about the types of cut, fold, and form machinery in use, their maintenance schedules, and how operators are trained to handle complex profiles. For metal roofing, where tight tolerances and weatherproof seams are non-negotiable, even minor inefficiencies can cascade into costly rework or warranty claims.

Another vital consideration is the manufacturer’s approach to integrating automation and process controls. Modern cut, fold, and form machines often come equipped with programmable logic controllers (PLCs) and digital readouts that enhance repeatability and reduce human error. During shop visits, I advise clients to evaluate not only the hardware but also the software and support infrastructure available. A manufacturer that invests in technology and continuous improvement is better positioned to adapt to changing market demands and product innovations.

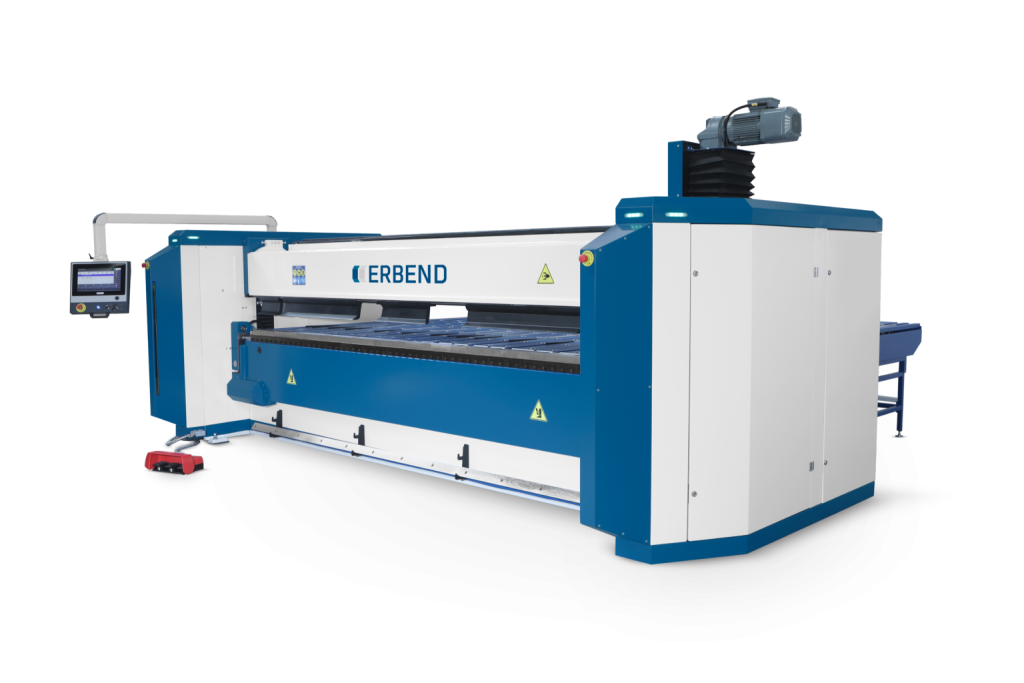

STEFA VHB620

Leveraging Mac-Tech’s Expertise in Cut, Fold, and Form Solutions for Downspout and Roofing Production

At Mac-Tech, we understand the intricacies of metal roofing and downspout production, which is why we specialize in providing tailored cut, fold, and form solutions that meet the unique needs of Indiana manufacturers. Our machines are designed to handle a wide range of metals and thicknesses, ensuring clean cuts and precise bends that enhance product integrity and visual appeal. We collaborate closely with our clients to analyze their production challenges and recommend equipment that improves efficiency without compromising quality.

Training and ongoing support are cornerstones of our customer service philosophy. We don’t just sell machinery; we partner with manufacturers to ensure their teams are fully equipped to operate and maintain the equipment effectively. This often involves on-site training sessions, detailed operational manuals, and remote troubleshooting assistance. By empowering our clients’ workforce, we help them reduce downtime and maximize return on investment, which is particularly critical in the competitive metal roofing industry.

Furthermore, Mac-Tech continuously innovates to keep pace with industry trends. Whether it’s developing new tooling for complex profiles or enhancing machine automation, we strive to provide solutions that future-proof manufacturing lines. Our commitment extends beyond the sale, as we work hand-in-hand with manufacturers to implement upgrades and process improvements that drive long-term success. This customer-centric approach has made us a trusted partner for many Indiana metal roofing producers seeking to elevate their capabilities.

FAQ

What maintenance practices ensure the longevity of cut, fold, and form machines?

Regular cleaning, lubrication, and inspection of critical components are essential. Following manufacturer-recommended maintenance schedules and promptly addressing wear parts help prevent unexpected breakdowns.

Can Mac-Tech’s machines handle different metal thicknesses and types?

Yes, our equipment is engineered for versatility, accommodating various metals such as aluminum, steel, and copper, with adjustable settings to manage different thicknesses effectively.

How does automation improve production efficiency in metal roofing manufacturing?

Automation reduces manual handling errors, increases repeatability, and speeds up cycle times, leading to higher throughput and more consistent product quality.

Is operator training included with Mac-Tech machinery purchases?

Absolutely. We provide comprehensive training tailored to your team’s experience level to ensure smooth integration and optimal machine performance.

What customization options are available for cut, fold, and form equipment?

We offer customizable tooling, programmable controls, and modular machine components to meet specific profile requirements and production volumes.

How quickly can Mac-Tech respond to service or support requests?

We prioritize rapid response times with remote diagnostics and on-site support options to minimize downtime for our clients.

Get Weekly Mac-Tech News & Updates