As the National Sales Executive at Mac-Tech, I have spent years working closely with Indiana’s metal roofing industry to provide machinery solutions that enhance manufacturing efficiency and product quality. The challenges faced by metal roofing and downspout manufacturers are unique, requiring tailored strategies to optimize both production and financial outcomes. One key area where I offer guidance is in leveraging Section 179 deductions and integrating advanced operator training. These strategies not only provide tax advantages but also promote faster technology adoption, reduce errors, and ensure a competitive edge.

Leveraging Section 179 for Metal Roofing Equipment Upgrades

Section 179 is a powerful tool for Indiana shops looking to upgrade their cut, fold, and form machinery. By taking advantage of this tax deduction, businesses can offset the costs of new equipment, improving their financial health while enhancing operational efficiency. Investing in advanced machinery allows for greater precision and speed in production, which translates to higher quality products and increased customer satisfaction.

At Mac-Tech, we assist our clients in identifying equipment that qualifies for Section 179 deductions. This includes not only the machinery itself but also software and controls that can be bundled with the purchase. By doing so, shops can maximize their tax benefits while simultaneously upgrading their capabilities. Our goal is to ensure that every investment contributes to both immediate and long-term success.

The benefits of these upgrades extend beyond financial savings. With improved machinery, shops can streamline their processes, reduce waste, and increase output. This efficiency is crucial in a competitive market, enabling Indiana shops to meet growing demand while maintaining high standards of quality. By strategically investing in equipment, businesses can position themselves for growth in the coming year.

Advanced Operator Training: Key to Maximizing New Equipment

Introducing new technology into a manufacturing environment can be challenging, which is why comprehensive operator training is essential. Proper training ensures that operators are comfortable and proficient with new systems, leading to smoother implementation and fewer errors. This is particularly important in metal roofing and downspout manufacturing, where precision and reliability are paramount.

At Mac-Tech, we offer advanced training programs tailored to the specific needs of our clients. By pairing operator training with Section 179 deductions, businesses can achieve a seamless transition to new equipment. This approach not only accelerates operator adoption but also minimizes downtime and maximizes productivity. Well-trained operators are more confident and efficient, contributing to overall operational success.

Investing in training is an investment in the future of your business. By empowering your team with the skills and knowledge they need, you can foster a culture of continuous improvement and innovation. This not only enhances the performance of your current operations but also prepares your business to adapt to future technological advancements.

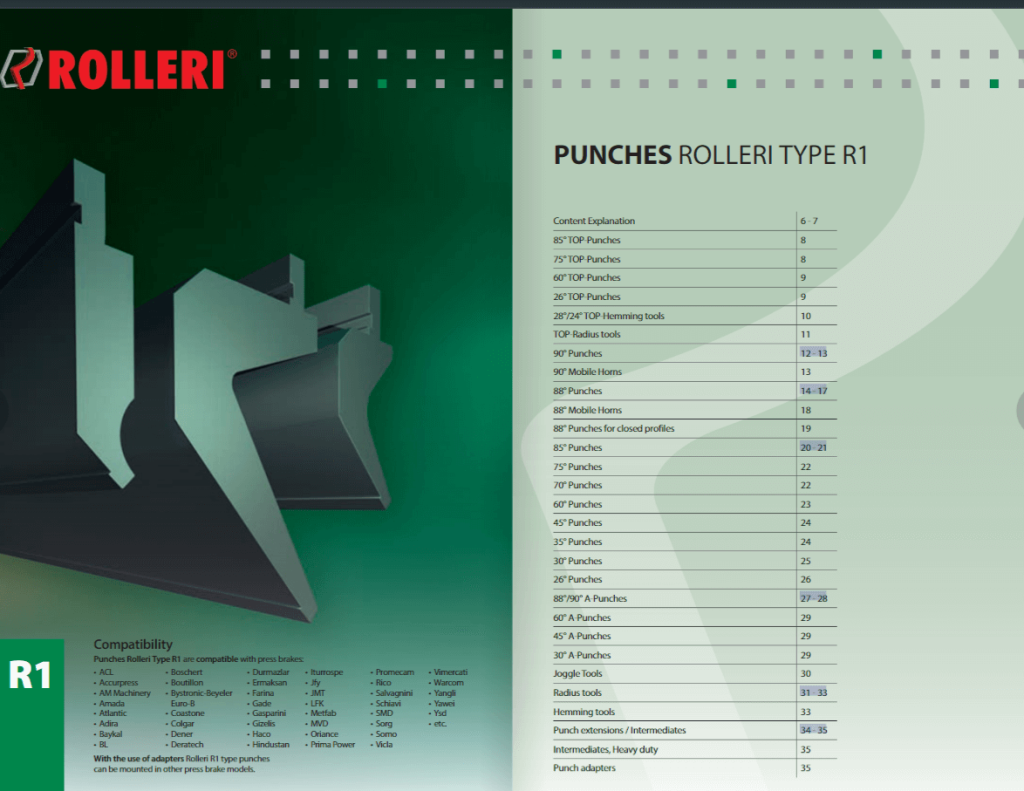

Rolleri Press Brake Tools Brochure

WILSON TOOL INTERNATIONAL

Tailored Solutions for Roofing Industry Success

Understanding the unique challenges of the metal roofing industry is essential to providing effective solutions. At Mac-Tech, we pride ourselves on delivering customized support that aligns with the specific operational needs and industry standards of our clients. Whether it’s recommending the right machinery or offering specialized training, our focus is on helping businesses achieve their goals.

Our team works closely with clients to assess their current capabilities and identify areas for improvement. By doing so, we can provide targeted recommendations that enhance both efficiency and product quality. Our solutions are designed to be scalable and adaptable, ensuring that they continue to meet the evolving needs of the industry.

Support doesn’t end with the sale. We provide ongoing assistance to ensure that our clients get the most out of their investments. From maintenance advice to software updates, our commitment to customer success is unwavering. By partnering with Mac-Tech, Indiana shops gain a reliable ally in their pursuit of excellence.

FAQ

How can I ensure my new equipment qualifies for Section 179?

Consult with a tax professional and work with us to select equipment that meets the IRS criteria for Section 179 deductions.

What types of training do you offer for operators?

We provide comprehensive training programs tailored to the specific machinery and software used in your operations.

How often should equipment be maintained to ensure efficiency?

Regular maintenance is essential; we recommend following the manufacturer’s guidelines and scheduling routine checks.

Can you customize equipment solutions for specific production needs?

Yes, we offer tailored solutions to meet the unique requirements of your production processes.

What support is available after purchasing equipment?

We offer ongoing support, including maintenance advice, software updates, and troubleshooting assistance.

I invite you to explore how these solutions can benefit your business. Whether you’re considering equipment upgrades or enhancing operator training, I’m here to help you navigate these opportunities. Feel free to reach out for personalized advice and support in achieving your manufacturing goals.

Get Weekly Mac-Tech News & Updates