A chiller alarm paired with slow hydraulic drift is one of the most common shop headaches I get pulled into, especially when the machine ran fine yesterday and suddenly the cylinder will not hold position today. As Service & Parts Lead at Mac-Tech, I keep production moving by confirming the exact machine configuration, identifying the correct OEM parts quickly, and coordinating service so the tech arrives with the right seals, hoses, sensors, or filtration components on the first trip. The fastest wins come from good commissioning documentation because it turns a stressful phone call into a targeted repair plan.

Commissioning Logs and Baselines That Reduce Unplanned Hydraulic Downtime

Most unplanned hydraulic leaks start as small changes operators miss, like a slightly longer cycle time, a new sheen of oil at a fitting, or a higher running temperature after a shift change. The systems typically involved are hoses and fittings, cylinders and seals, pump and motor groups, manifolds and valves, filtration, and any heat exchanger or chiller loop that keeps viscosity stable. The practical fix is usually straightforward once the failure mode is confirmed, like replacing a hose assembly, resealing a cylinder, correcting an alignment or clamp issue, then verifying pressure stability, temperature, and clean, dry connections after the repair.

Commissioning package I ask for

- Machine model and serial, hydraulic schematic, and reservoir capacity and fluid spec

- Clear photos of the power unit, manifold, filter head, cylinder ports, hose routing, and label plates

- Baseline pressures at key test points, baseline oil temperature at normal production, and cycle time targets

- Filter type and micron rating, initial differential pressure, and a contamination control plan

- Leak log template for location, drip rate, temperature, and operating condition when observed

For prevention, I recommend a 5 minute visual check per shift for seepage and abrasion points, a weekly check of reservoir level and filter indicator, and a monthly review of trend notes against commissioning baselines. When you need replacements, ordering by OEM configuration prevents rework and lets us ship the right assemblies fast from https://shop.mac-tech.com/.

ERMAKSAN SPEED BEND PRO

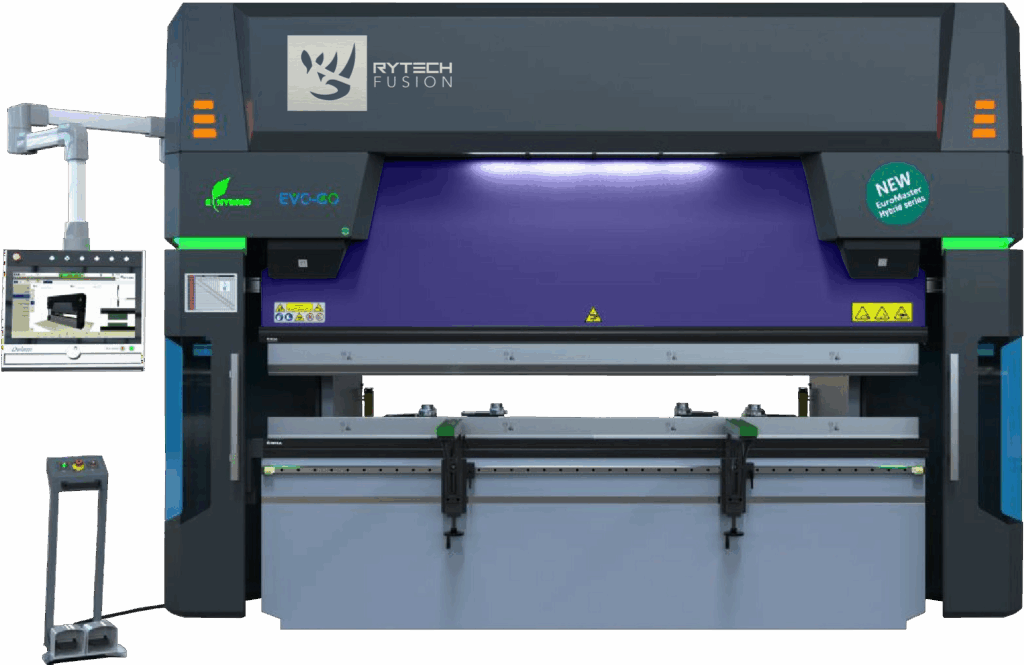

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Early Wear Detection Using Leak Rate Trends, Pressures, and Cycle Time Baselines

Leaks accelerate when pressure spikes, heat, and vibration stack up, but early warning signs are often subtle, like a valve that needs more adjustment, a cylinder that creeps only when warm, or a pump that sounds slightly rough during startup. The affected categories are pumps, proportional or directional valves, cylinders, accumulators, pressure switches or transducers, and the cooling and filtration loop that keeps the hydraulic system stable. The practical approach is to compare current readings to commissioning baselines, then isolate by test point or section, repair the root cause, and confirm the system returns to baseline pressure, temperature, and cycle time.

Baselines that make troubleshooting fast

- Cycle time per operation at normal load and normal oil temperature

- Pump outlet pressure and any critical branch pressures during a known good cycle

- Return line and case drain observations, plus temperature at tank and cooler outlet

- Leak rate tracking by location using a simple drops per minute or ml per hour estimate

- Photos of normal hose routing, clamp positions, and typical dry surfaces for comparison

For prevention, trend review should be monthly for high duty equipment and quarterly for lower duty machines, with immediate follow up if cycle time changes by more than a few percent or if leak rate increases week over week. If you also use centralized monitoring, pairing those readings with your commissioning photos and logs helps my team and your techs avoid guesswork, and platforms like https://vayjo.com/ can support organized service records and response coordination.

Predictable Maintenance Planning to Extend Hose, Seal, and Pump Life

Most repeat hydraulic leaks come from treating the symptom instead of the cause, such as replacing a hose without addressing abrasion, replacing a seal without correcting side load or misalignment, or chasing pressure issues without checking filtration and fluid condition. The parts most often involved at a category level are hose and fitting assemblies, cylinder seal kits, pumps, shaft seals, filter elements, breathers, and coolers or chillers. The right fix is a planned replacement using OEM correct materials and routing, followed by post repair checks for pressure stability, zero rub points, correct clamp spacing, proper torque, clean mating surfaces, and a dry run under normal load.

A realistic cadence is a quick daily look for rub and seep points, weekly inspection of hose clamps and strain relief, monthly filter indicator and temperature trend review, and semiannual fluid sampling or condition checks depending on duty cycle and environment. When you plan maintenance against baselines, you avoid emergency freight, you reduce oil loss and cleanup, and you protect pumps and valves from contamination that starts with a small leak and ends with a big failure.

Getting Parts and Service Support from Nicole Salato at nicole@mac-tech.com

When you call or email me, the fastest path to the right repair is accurate machine identity plus commissioning documentation that shows what normal looks like. Operators often miss the early signs like a small change in cycle time, a hotter tank after a long run, or a fitting that is damp only at full pressure, but photos and baseline readings let me pinpoint likely failure points across hoses, cylinders, valves, pumps, filtration, and cooling. My role is to coordinate OEM accurate parts, verify compatibility, and align service timing so the tech arrives ready to fix and verify, not troubleshoot from scratch.

After the repair, I want confirmation of the same baselines we started with, including target pressure ranges at key points, stable oil temperature, dry fittings, and consistent cycle time across a few production cycles. For ordering and spares planning, you can pull common hydraulic maintenance items and service essentials at https://shop.mac-tech.com/, and I can help you build a short list that matches your exact equipment configuration.

FAQ

How often should we service brakes, lasers, saws, and rolls?

As a practical range, inspect brakes and rolls monthly and service every 6 to 12 months depending on hours and environment, while lasers and saws benefit from weekly checks and quarterly to semiannual preventive service. Use your commissioning baselines to adjust intervals based on drift in performance, temperature, or cycle time.

How do we spot hydraulic wear before it becomes downtime?

Track leak rate by location, compare cycle time to the baseline, and watch for temperature or noise changes that appear only under load. A small seep plus a slow cycle is often the earliest sign of seal, hose, or valve wear.

What information should I send so you can identify the right part fast?

Send machine model and serial, photos of the affected area and label plates, alarm codes if present, and any baseline pressures or cycle times from commissioning. A short video of the leak under operation can also help confirm whether it is pressure side or return side.

OEM vs non-OEM parts for hydraulic repairs, what is the real risk?

Fit and material compatibility matter, especially for seals, hose assemblies, and valves where small differences cause repeat leaks or performance drift. OEM accurate parts reduce rework, shorten service calls, and protect pumps and valves from contamination caused by repeat failures.

What spares should we keep on hand to protect uptime?

Keep common filter elements, breathers, a small set of hose and fitting assemblies that match your routing, and critical seal kits for high cycle cylinders. The best spare list is driven by your commissioning bill of materials and your leak and failure history.

What post-repair checks prevent repeat leaks?

Confirm the system returns to baseline pressure, temperature, and cycle time, and recheck for rub points, clamp security, and clean, dry fittings after a short warm run. Document the final readings and photos so the next service event is even faster.

Contact me at nicole@mac-tech.com to schedule preventive maintenance, coordinate service, or get OEM parts support through https://shop.mac-tech.com/.

Get Weekly Mac-Tech News & Updates