Maximizing ROI: Liberty Systems Automation in Structural Fabrication

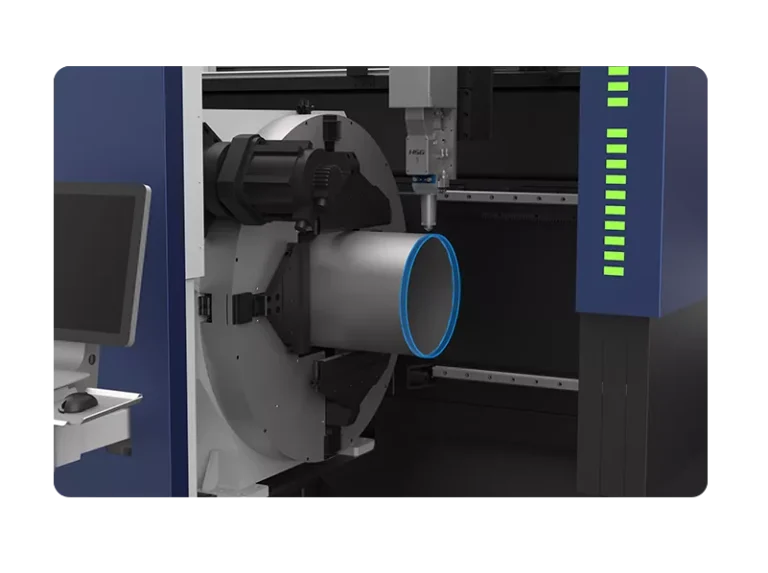

Dave Graf, Regional Sales Executive at Mac-Tech, explores how Liberty Systems Automation enhances ROI in structural steel fabrication. Ideal for decision-makers in oil & gas, shipbuilding, and construction, this article highlights streamlined processes and Dave’s pivotal role in delivering comprehensive automation solutions.