MVD iBend A-1250-40 – Precision CNC Brake, Low Usage

This precision CNC brake offers reliable, low-usage performance to streamline fabrication, enhance accuracy, and increase production efficiency. Contact Mac-Tech for details: 888-MAC-9555.

This precision CNC brake offers reliable, low-usage performance to streamline fabrication, enhance accuracy, and increase production efficiency. Contact Mac-Tech for details: 888-MAC-9555.

In this insightful article, John Perry, Regional Sales Executive at Mac-Tech, shares his extensive experience advising fabricators on selecting the ideal equipment partner. Drawing from years of deep industry knowledge, John emphasizes the critical importance of aligning press brakes, lasers, and tooling solutions with specific operational needs. He advocates for a consultative, solutions-driven approach that prioritizes understanding the unique challenges faced by fabricators, ultimately leading to enhanced productivity and efficiency. One key challenge highlighted is the common misalignment between equipment capabilities and production requirements, which can lead to costly inefficiencies. John offers actionable insights and strategies to help decision-makers navigate this complex landscape, ensuring they choose equipment that not only meets current demands but also supports future growth. This article is a must-read for C-suite executives looking to optimize their operations and drive sustainable success in a competitive market.

In this insightful article, Pat O’Neill, National Sales Executive at Mac-Tech, shares his expert perspective on Ermaksan’s latest advancements in laser welding technology and their transformative impact on metal roofing manufacturing. Drawing from years of industry experience, Pat highlights how these innovative machines deliver unmatched precision, efficiency, and durability—key factors that drive superior product quality and streamlined production processes. Committed to offering tailored solutions that meet the unique needs of each client, Pat encourages manufacturers to explore these cutting-edge developments as a pathway to enhancing operational performance and staying ahead in a competitive market.

In this insightful article, John Perry, Regional Sales Executive at Mac-Tech, delves into the critical considerations for shops contemplating the integration of fiber lasers with automation. Drawing on his extensive industry expertise, John presents a comprehensive capacity checklist that evaluates essential factors such as press brake compatibility, tooling solutions, and workflow efficiency. He emphasizes the importance of a consultative, solutions-driven approach to ensure that decision-makers not only understand the potential of fiber lasers but also how to seamlessly incorporate them into existing operations for maximum productivity. As the manufacturing landscape evolves, John highlights a pressing challenge: the need to balance investment with operational readiness. By addressing this challenge head-on, he offers strategic insights that can lead to significant efficiency gains and competitive advantages. Decision-makers are encouraged to explore these key considerations further, ensuring their shops are not just ready for fiber lasers but primed for success in a rapidly advancing industry.

As a local expert, I’m committed to helping you select the best roll former for your gutter line, ensuring quality and efficiency every step of the way. – Pat O’Neill, Mac-Tech (pat@mac-tech.com, 414-232-7929)

**Maximizing Efficiency and Accuracy in Beam Processing with Prodevco’s PCR41: A Game Changer for C-Suite Leaders in High-Stakes Industries** In an era where precision and productivity are paramount, C-suite leaders in structural steel, oil & gas, bridge, shipbuilding, and high-rise industries face an urgent challenge: how to optimize beam processing to meet escalating demands while maintaining stringent quality standards. In this compelling article, Dave Graf, Regional Sales Executive at Mac-Tech, unveils the transformative potential of Prodevco’s PCR41, a cutting-edge solution designed to revolutionize the way high-stakes industries approach beam processing. Graf emphasizes that the PCR41 is not just another tool; it’s a strategic asset that can significantly enhance operational efficiency and accuracy, ultimately driving profitability and competitive advantage. By integrating this advanced technology, leaders can streamline workflows, reduce material waste, and minimize costly errors—factors that are critical in industries where margins are thin and stakes are high. As the single point of contact for structural steel processing solutions, Graf brings a wealth of expertise and insight to the table, ensuring that decision-makers are equipped with the knowledge they need to make informed choices. He challenges C-suite leaders to rethink their current processes and consider the profound implications of adopting innovative technologies like the PCR41. Are you ready to seize the opportunity to elevate your operations and outpace your competition? Dive into this article to discover how embracing the PCR41 can redefine your approach to beam processing and position your organization for unprecedented success.

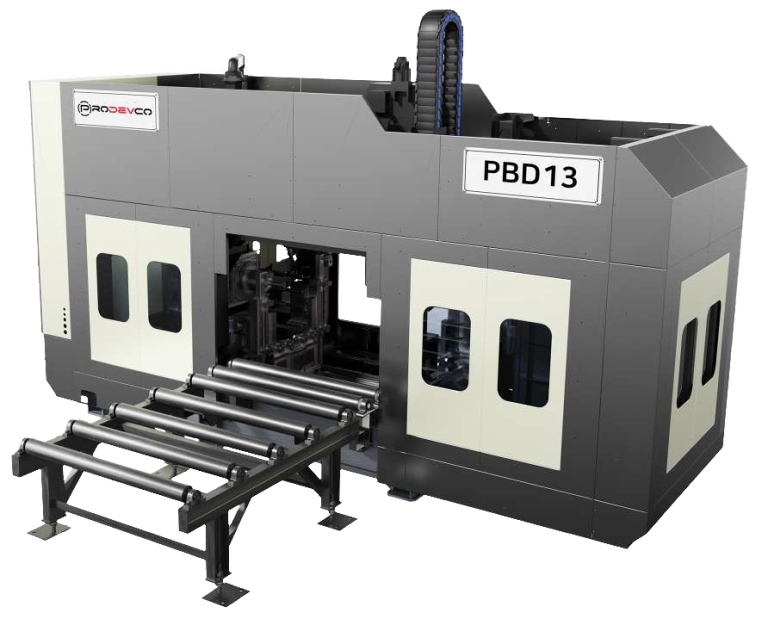

This precision drilling machine enhances efficiency and accuracy, enabling businesses to meet production targets and increase profitability. Contact Mac-Tech: 888-MAC-9555.

**Debunking Myths: How On-Site Nitrogen Generation Transforms Fabrication Efficiency and Cost Savings** In the fast-paced world of fabrication, myths surrounding nitrogen generation can cloud decision-making and hinder operational efficiency. In this enlightening article, Joe Ryan, a seasoned Sales Engineer at Mac-Tech, dismantles common misconceptions about on-site nitrogen generation and reveals how it can revolutionize your fabrication processes. With a keen understanding of the industry’s challenges, Nathan illustrates the tangible benefits of adopting this technology, from significant cost savings to enhanced production efficiency. Are you still relying on traditional nitrogen supply methods that drain your resources? Discover how embracing on-site generation not only streamlines operations but also positions your business for sustainable growth. Dive in to explore the transformative power of nitrogen generation and unlock the potential for your fabrication success.

**Overview** In this insightful article, Pat O’Neill, National Sales Executive at Mac-Tech, explores the transformative impact of Ermaksan’s fiber laser cutting machines on metal roofing manufacturing. Pat delves into the key advantages of these advanced machines, including increased precision, reduced waste, and enhanced production speed, all of which contribute to greater operational efficiency. Drawing from his extensive expertise in the industry, Pat emphasizes his commitment to providing tailored solutions that meet the unique needs of clients, ensuring they stay competitive in a rapidly evolving market. Readers are encouraged to reflect on these insights and consider how integrating fiber laser technology can elevate their own manufacturing processes and drive success in their operations.

End of content

End of content