Why 6000W Tube Lasers Deliver Optimal ROI for Mid-Sized Structural Fabrication

John Perry guides buyers to boost efficiency and profits by choosing the ideal laser or press brake system tailored to their fabrication needs.

John Perry guides buyers to boost efficiency and profits by choosing the ideal laser or press brake system tailored to their fabrication needs.

In this article, Pat O’Neill, National Sales Executive at Mac-Tech, shares valuable insights on minimizing CNC downtime through strategic preventive control assessments, specifically tailored for the metal roofing manufacturing sector in Indiana. Drawing on extensive industry experience, Pat highlights how proactive maintenance and targeted evaluations can significantly boost machine reliability, enhance production efficiency, and reduce costly interruptions. His expert guidance underscores a commitment to delivering customized solutions that address the unique challenges faced by manufacturers. Readers are invited to explore these practical strategies to optimize their operations, ensuring sustained productivity and competitive advantage in a demanding market.

Dave Graf, Regional Sales Executive at Mac-Tech, highlights how Prodevco Automation can significantly enhance ROI in Arizona’s construction sector. Tailored for decision-makers in structural steel fabrication, this article emphasizes streamlined solutions for industries like oil & gas, shipbuilding, and infrastructure.

Kyle Bialozynski shares expert insights on the Prodevco PCR42, highlighting smart fabrication, ROI, and his dedication to customer satisfaction. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

Nicole Salato shares key tips on HSG laser wear parts maintenance, helping customers prevent breakdowns with proactive service and expert parts sourcing. Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

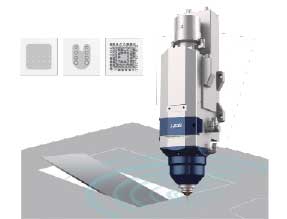

Dave Graf, Regional Sales Executive at Mac-Tech, explores how HSG Tube Lasers elevate ROI for decision-makers in structural steel fabrication. Tailored for industries like oil & gas, shipbuilding, and construction, the article highlights Graf’s expertise as a key contact for automation solutions.

This article explores how used Trumpf, Amada, and HSG lasers help Illinois shops boost precision, cut costs, and solve major production issues. Contact Mac-Tech: 888-MAC-9555

Investing in advanced press brakes boosts productivity, reduces waste, and ensures long-term profitability in structural fabrication. Joe Ryan President, Mac-Tech joe@mac-tech.com | 414-477-8772 | 888-MAC-9555

Patrick (Pat) O’Neill, National Product Manager and Regional Sales Executive at Mac-Tech, discusses how combi-beam folders offer manufacturers increased efficiency and versatility for multi-profile forming. Drawing on his expertise, Pat explains how integrating advanced folding, roll forming, and coil-fed fabrication systems can help customers streamline production, reduce material handling, and achieve greater flexibility in their operations. He works closely with clients to identify solutions that optimize workflow and enhance overall productivity. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929

End of content

End of content