Maximize ROI with Mac-Tech’s Turnkey Steel Line Upgrades

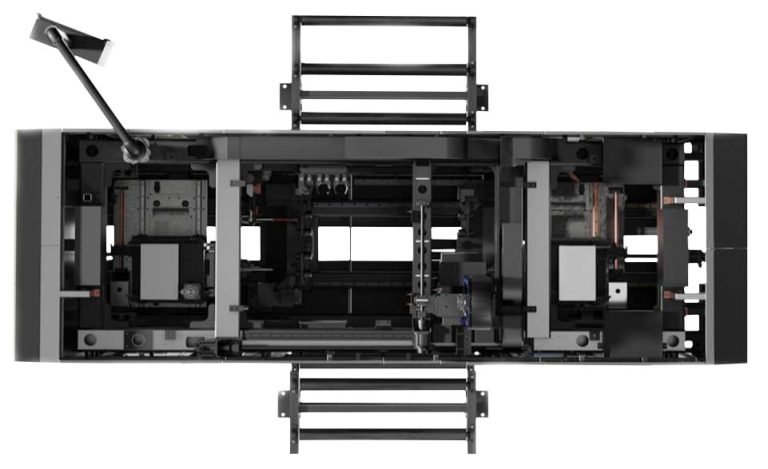

Dave Graf, Regional Sales Executive at Mac-Tech, explores how turnkey steel line upgrades boost ROI for decision-makers in structural steel sectors like oil & gas, shipbuilding, and construction. As a single contact point, Dave ensures seamless automation solutions tailored to industry needs.