How I Eliminate Downtime for Metal Roofing Machines with Preventative Maintenance

I prioritize your needs. Preventive maintenance avoids downtime and extends metal roofing machines life. Pat O’Neill, Mac-Tech (pat@mac-tech.com | 414-232-7929)

I prioritize your needs. Preventive maintenance avoids downtime and extends metal roofing machines life. Pat O’Neill, Mac-Tech (pat@mac-tech.com | 414-232-7929)

Discover how Automated Prodevco Beam Drilling reshapes structural steel fabrication—and your bottom line—in this exclusive insight from Dave Graf, Regional Sales Executive at Mac-Tech. By harnessing cutting-edge robotic drilling systems, today’s most forward-thinking companies are slashing production times, eliminating costly errors, and outpacing competitors. For C-Suite decision-makers, the stakes are high: delays mean lost contracts and shrinking margins, while faster, more precise operations open doors to new revenue and market dominance. Dave’s expert perspective reveals how strategic investments in automation can create sustainable growth and ROI across the entire fabrication process—read on to find out why the time to act is now.

In this expert-driven overview, Joe Ryan, Sales Engineer at Mac-Tech, explains how fabricators can achieve higher productivity and financial efficiency by switching from bulk nitrogen to on-site generation. With first-hand insight into the challenges that shops face—ranging from inconsistent supply to unpredictable costs—Nathan provides a clear strategy for stabilizing operations and safeguarding against production downtime. Discover how on-site nitrogen not only cuts expenses but also streamlines manufacturing, helping you gain a competitive edge. Could this be the key to elevating your fabrication processes and boosting profitability? Read on to find out.

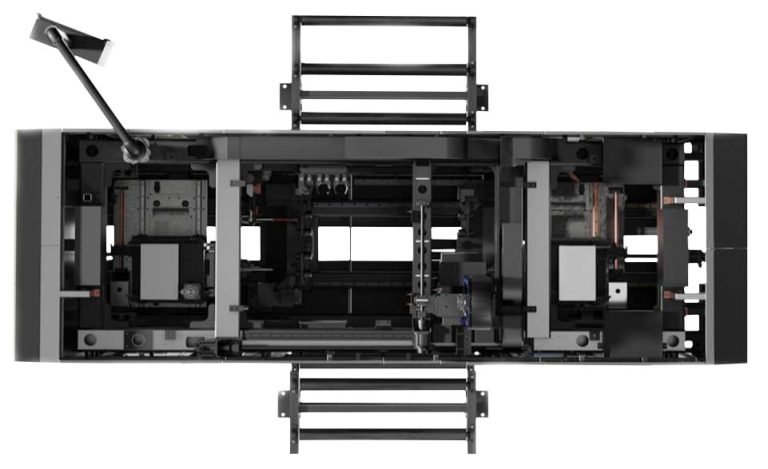

The Ficep Excalibur-12 CNC Beam/Drill Line, a 2013 model, enhances manufacturing efficiency with precision drilling and versatility. This advanced equipment enables businesses to achieve production goals and maximize profitability. For more information, contact Mac-Tech at 888-MAC-9555.

I show how tech imports elevate metal fab efficiency & reach, fueling innovation and growth – Joe Ryan, Mac-Tech joe@mac-tech.com | 414-477-8772 | 888-MAC-9555

I ensure Accurshear solutions boost clients’ satisfaction. Adam Quoss Vice President of Sales, Mac-Tech aquoss@mac-tech.com

John Perry, Regional Sales Executive at Mac-Tech, reveals how empowering operators is the key to unlocking peak press brake, laser, and tooling performance. Drawing on his deep industry expertise and consultative, solutions-first approach, John pinpoints the critical challenges that often hold back efficiency—from skill gaps to insufficient tooling strategies—and shows how to address them with targeted interventions. Discover how strengthening your workforce’s confidence and capabilities can streamline production, curb downtime, and drive measurable, profitable outcomes.

My local roots and customer-first focus drive gutter & downspout roll formers that provide top tier metal solutions. Pat O’Neill (pat@mac-tech.com, 414-232-7929)

Accelerating structural steel fabrication can be the decisive edge in meeting rising demand and boosting bottom-line results. In this article, Dave Graf, Regional Sales Executive at Mac-Tech, demonstrates how high-speed beam drilling automation can compress production timelines, minimize costly errors, and elevate overall profitability. By spotlighting key strategic moves and real-world successes, Dave offers a roadmap for forward-thinking leaders looking to outpace the competition in an increasingly fast-paced market. Ready to redefine what’s possible in your fabrication process? Dive in to discover how you can future-proof operations and deliver measurable ROI.

End of content

End of content