Labor shortages, variable material flow, and tight ship, bridge, and energy delivery windows are colliding with aging equipment and inconsistent process control. The result is predictable: queues at the burn table, unplanned downtime on drilling and coping, and overtime that still fails to protect critical milestones. I am Dave Graf, Regional Sales Executive at Mac-Tech, and my role is to be the single point of contact who coordinates staged, ROI-focused automation so you can pilot, validate, and expand without jeopardizing delivery commitments.

Delivery Risk Drivers in Structural Fabrication Automation Programs

Delivery risk typically starts upstream, where inconsistent cutting and prep accuracy cascades into fit-up, weld delays, and rework. In bridge and shipyard work especially, a missed nesting plan or material handling bottleneck can add days of queue time and force schedule compression later in the project.

Common operational drivers that disrupt delivery dates

- Labor variability: 1–2 open operator roles can cut effective capacity by 20–35% on a two-shift plan

- Process bottlenecks: parts waiting 8–24 hours between plate cutting, beveling, and drilling due to batch scheduling

- Rework from prep variation: 3–8% rework rate driven by inconsistent hole quality, bevel angle, or part ID traceability

- Downtime exposure: single-point failures (torch table, drill line, forklift availability) that create same-day stoppages

- Handling risk: multiple crane and forklift touchpoints increasing damage, safety incidents, and mis-pulls

A staged automation roadmap reduces these risks by prioritizing the stations that most directly protect delivery dates: controlled plate processing, repeatable beam drilling and coping, and material handling that reduces touchpoints and searching.

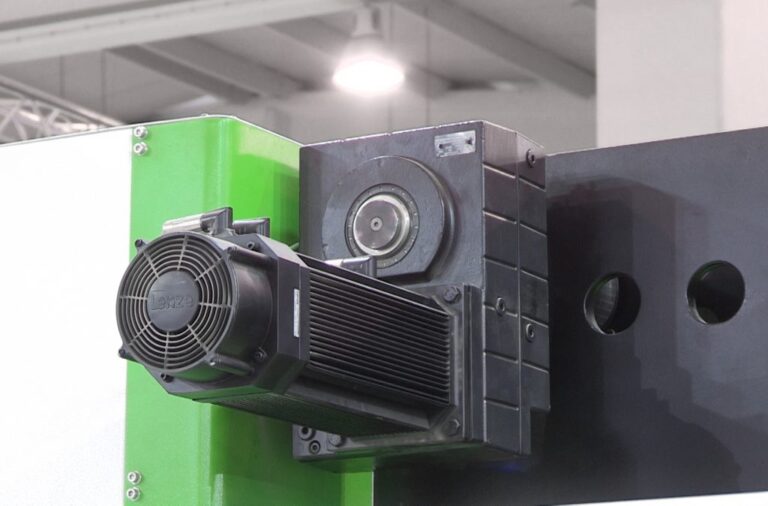

G-FORCE FIBER LASER

HEAVY SERIES ANGLE ROLL BENDING MACHINE

Decision Criteria for Phased Automation and Integration Investments

Executives should evaluate phased investments based on delivery protection first, then unit cost and labor impact. The best stage-one projects are the ones that can run alongside existing processes, validate cycle time assumptions, and avoid a plant-wide disruption.

Decision criteria that support phased execution

- Parallel run capability: ability to keep current line active while piloting new equipment for 30–90 days

- Measurable bottleneck relief: targeted reduction of queue time by 25–50% at the constrained operation

- Staffing realism: automation that reduces dependency on scarce skills and stabilizes coverage for 2 shifts

- Integration scope control: clear boundaries for layout, utilities, software, and material flow to prevent open-ended changes

- Service continuity: defined uptime plan with spares, response windows, and training to protect peak production months

Where applicable, systems like Prodevco for beam processing or HSG Fiber Lasers for plate cutting can be staged so output quality is proven before downstream processes are forced to change.

Staged Automation Roadmap Options Across Beam Line, Plate Processing, and Material Handling

A staged roadmap should match your product mix and the delivery risks you face: high-mix bridge girders, shipyard panel lines, or energy skids and towers. The point is not to automate everything at once, but to automate the constraint and lock in repeatability.

Stage 1: Pilot the constraint and validate quality

- Plate processing: HSG Fiber Lasers to stabilize cut quality, reduce secondary grinding, and shorten cut-to-kit time by 20–40%

- Beam processing: Prodevco beam drilling and coping to standardize hole location and coping repeatability, reducing fit-up delays by 1–3 hours per assembly

- Bending and forming support: Akyapak, Ermaksan, or Ercolina when your roadmap includes consistent formed components with controlled setup time and repeatable angles

Stage 2: Expand throughput and reduce touchpoints

- Add automated sorting, part marking, and kitting logic to reduce mis-pulls and material searching by 30–60 minutes per job

- Standardize programming and revision control so engineering changes do not create scrap or “mystery parts” on the floor

Stage 3: Integrate material handling for delivery reliability

- Liberty material handling solutions to reduce crane and forklift touchpoints, improving safety and stabilizing flow

- Target 2–4 fewer lifts per part and a measurable reduction in WIP congestion around critical stations

For executives planning capex, Mac-Tech can help you compare staged approaches and equipment options through practical budgeting and configuration tools at https://shop.mac-tech.com/.

Implementation Risk Controls with Dave Graf as Single Point of Contact for Integration

The biggest implementation risk is not the machine, it is the interruption to production during layout changes, utilities, software setup, and training. My job is to coordinate the full sequence so your team is not managing multiple vendors, conflicting timelines, or unclear commissioning responsibilities.

Risk controls I manage end-to-end

- Layout and flow planning: confirm infeed and outfeed, crane paths, and staging zones to avoid creating a new bottleneck

- Installation scheduling: align rigging, electrical, air, and foundation work with production windows to limit disruption to planned weekends or defined outage blocks

- Commissioning discipline: acceptance tests tied to cycle time, cut quality, and repeatability so performance is validated before you rely on it for delivery

- Training and handoff: operator, programmer, and maintenance training with documented start-up checklists and PM routines

- Long-term service continuity: coordinated service plans and spare parts strategy so uptime is protected after the initial ramp

When projects include multiple systems, I remain the one-call coordinator for integration scope, sequencing, and accountability from planning through sustained production.

KPIs and Measurable Outcomes to Validate Each Automation Stage

A staged roadmap only works if each phase has measurable success criteria that justify expansion. The objective is to convert assumptions into proven production data without gambling on full-plant change.

Stage-specific KPIs executives can track

- Throughput and flow: increase parts produced per shift by 15–35% and reduce queue time between operations by 25–50%

- Labor and coverage: reduce manual touch labor by 0.5–2.0 FTE per shift at the targeted station while improving staffing stability

- Quality and rework: lower rework rates from 3–8% to 1–3% through consistent cutting, drilling, beveling, and part identification

- Uptime and reliability: sustain 85–95% planned production availability with documented PM completion and spares readiness

- Safety and handling: cut forklift or crane touchpoints by 2–4 per part and reduce congestion in high-risk zones

These metrics are reviewed during pilot operations so leadership can approve stage-two and stage-three expansions with confidence instead of optimism.

Next Steps for Structural Fabricators to Align Roadmaps, Budget, and Execution

Start by mapping your current delivery risks to the actual constraints: where does work wait, where does quality drift, and where do you depend on hard-to-staff roles. Then build a phased plan that protects production, validates performance, and scales only after the pilot numbers are real.

Practical next steps

- Identify the top constraint and set a pilot target like 20% queue-time reduction or 1% rework improvement within 60–90 days

- Define a staged capex plan with clear success gates for expansion and a schedule that avoids peak delivery months

- Use planning and configuration resources from https://shop.mac-tech.com/ to shortlist options and build an initial budget range

If you need deeper coordination across programming, nesting, or workflow digitization, operational planning tools and support resources can also be aligned through https://vayjo.com/ when it directly supports your automation stage goals.

FAQ

How long are typical lead times for staged automation equipment?

Lead times vary by configuration and workload, but I plan around your delivery calendar and confirm realistic dates before you commit.

Can we pilot automation without shutting down existing production?

Yes. The roadmap is designed for parallel runs, with acceptance testing before the new system becomes production-critical.

What is the biggest integration risk executives overlook?

Material flow and handling. If infeed, outfeed, and staging are not designed, a faster machine can still increase WIP and delivery risk.

Who trains operators and maintenance, and how long does it take?

Training is planned as part of commissioning and typically includes operator, programmer, and maintenance sessions with documented checklists to shorten ramp time.

How do we protect uptime after commissioning?

We define PM routines, spares strategy, and service response expectations up front, and I coordinate continuity across the integrated systems.

How should we measure ROI without overstating it?

Track stage KPIs like throughput per shift, rework rate, and queue time reduction, then convert those verified gains into cost and delivery reliability impacts.

Contact Dave Graf for planning, demonstrations, or full project coordination: dave@mac-tech.com | 602-510-5552 | https://shop.mac-tech.com/

Get Weekly Mac-Tech News & Updates