As the VP of Sales at Mac-Tech, I’ve had the privilege of working with numerous fabrication shops across the Midwest. One consistent challenge I’ve observed is optimizing material flow to increase productivity and reduce waste. In Indiana, where manufacturing is a cornerstone of the economy, efficient material processing is essential. That’s where Hydmech automated saws come into play, revolutionizing how shops handle cutting tasks.

Challenges in Material Flow for Indiana Fabrication Shops

Fabrication shops in Indiana often struggle with bottlenecks in their cutting processes. These bottlenecks can lead to delays, increased labor costs, and material waste. The traditional manual methods are not only time-consuming but also prone to errors that affect the overall workflow. It’s clear that without addressing these issues, shops can’t maximize their throughput.

Insights into the Impact of Inefficient Cutting Processes

Inefficient cutting processes don’t just slow down production; they impact the bottom line. Inaccurate cuts lead to material scrap, which is both costly and wasteful. Additionally, the time lost in reworking parts or waiting for a machine to be available can result in missed deadlines and unhappy customers. These inefficiencies add up, eating into profits and competitiveness.

Leveraging Hydmech Saws for Enhanced Efficiency

This is where Hydmech automated saws make a difference. By incorporating advanced technology, these saws streamline the cutting process, reducing downtime and increasing accuracy. Shops that have transitioned to Hydmech saws report significant improvements in their material flow, allowing them to take on more work without sacrificing quality.

The Role of Programmable Feeds and Automatic Indexing

Programmable feeds and automatic indexing are game-changers. By automating these elements, Hydmech saws ensure precise and consistent cuts with minimal human intervention. This not only speeds up the process but also enhances the accuracy of each cut, reducing waste and improving the overall quality of the finished product.

HYDMECH CSNC-65

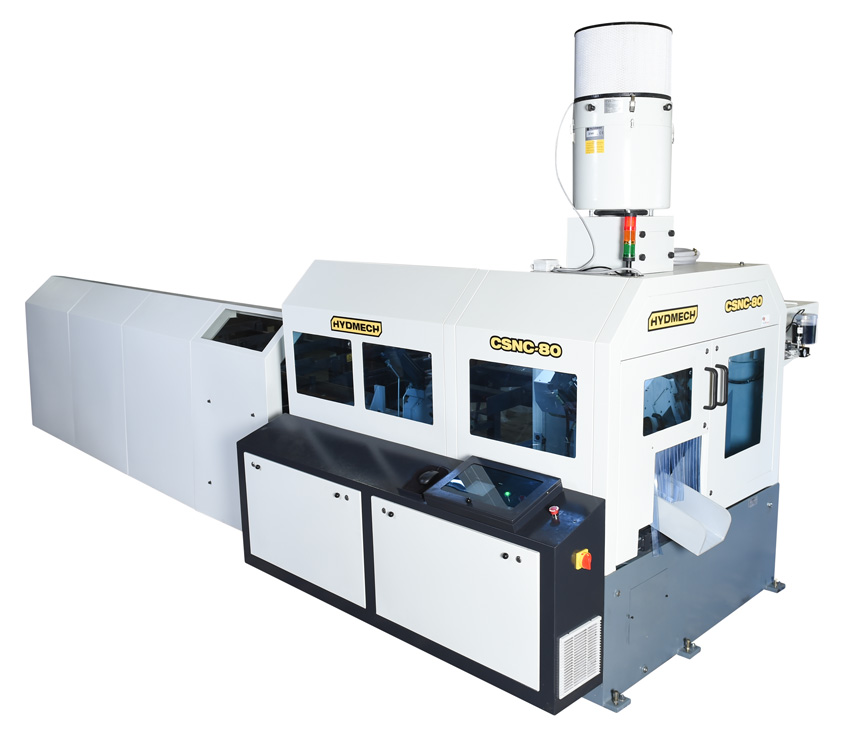

HYDMECH CSNC-80

Achieving Precision and Consistency in Cuts

Precision and consistency are critical in fabrication. With Hydmech saws, shops achieve a level of accuracy that was previously difficult to attain. The technology allows for repeated precision cuts, ensuring each piece meets the exact specifications. This reliability reduces the need for rework and enhances customer satisfaction by delivering high-quality products on time.

Next Steps for Modern Fabricators in Indiana

For fabrication shops in Indiana looking to modernize, embracing automation with Hydmech saws is a strategic move. Investing in this technology not only optimizes material flow but also positions shops to be more competitive in a demanding market. At Mac-Tech, we’re committed to supporting this transition and helping shops unlock their full potential.

FAQ Block

How does the ROI of Hydmech saws compare to traditional methods?

The ROI is typically higher due to increased efficiency and reduced waste, leading to quicker payback periods.

Is training required to operate these automated saws?

Yes, but it’s straightforward. We provide comprehensive training to ensure your team is comfortable and proficient.

Are Hydmech saws compatible with existing shop equipment?

Absolutely. They are designed to integrate seamlessly with most existing systems.

What about maintenance and uptime?

Hydmech saws are engineered for durability with minimal maintenance, ensuring high uptime.

Can these saws handle different materials?

Yes, they are versatile and can handle a wide range of materials with precision.

If you’re looking to enhance your shop’s efficiency and material flow, I invite you to reach out. Let’s talk shop and explore how Hydmech saws can make a difference for your business.

Get Weekly Mac-Tech News & Updates