As a Sales Executive at Mac-Tech, I’ve spent years helping Wisconsin’s steel contractors streamline their operations. My Midwest work ethic and technical background drive my approach to solving real-world fabrication challenges. I’m here to share how Prodevco’s advanced automation systems can transform your production line, improve efficiency, and enhance your bottom line.

Discover How Prodevco Automation Transforms Steel Fabrication

Prodevco’s fully automated beam coping and drilling systems are revolutionizing steel fabrication. Imagine replacing multiple manual steps with a seamless, automated process. These systems handle everything from cutting to drilling with precision, reducing the need for manual intervention. This not only speeds up production but also minimizes errors, ensuring consistent quality.

For those dealing with high-volume structural projects, the integration of 3D programming is a game-changer. It allows for detailed, accurate layouts that significantly cut down on rework. You’ll find your team spending less time on corrections and more on productive tasks.

Maximize ROI with Cutting-Edge Automation Solutions

Investing in Prodevco’s technology means seeing a substantial return on investment. The immediate benefits include reduced labor costs and increased throughput. By automating repetitive tasks, you free up skilled workers to focus on more complex projects, maximizing their potential and your profits.

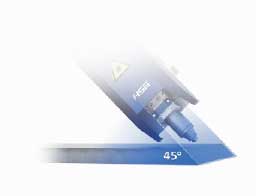

Consider the Prodevco PCR42 robotic plasma cutting system. It’s designed to handle tough materials with ease, ensuring precision and reducing waste. This kind of efficiency translates directly into savings and allows for faster project completion, boosting your ROI.

PCR41 ROBOTIC PLASMA CUTTING SYSTEM

PRODEVCO PCR42 ROBOTIC PLASMA CUTTER

Boost Efficiency with Tailored Prodevco Technology

Prodevco’s systems are not one-size-fits-all. They’re tailored to meet the specific needs of your operation. Whether it’s beam coping, drilling, or plasma cutting, these machines are designed to integrate seamlessly into your existing workflow.

Prodevco’s technology also reduces material handling, a major time sink in traditional fabrication. By streamlining the assembly process, you can move materials through your shop faster and more efficiently, increasing your overall output without sacrificing quality.

Enhance Growth Opportunities Through Advanced Integration

The advanced integration capabilities of Prodevco’s systems open up new growth opportunities. By adopting these cutting-edge technologies, you position your company as a leader in the industry, ready to take on larger and more complex projects.

The ability to deliver high-quality results quickly and efficiently sets you apart from competitors. This reputation for excellence can lead to more contracts and long-term partnerships, further fueling your growth.

Experience Firsthand Success with Mac-Tech’s Expert Guidance

At Mac-Tech, we’re committed to guiding you through the transition to automated systems. Our team is here to ensure you experience the full benefits of Prodevco’s technology. From initial consultation to installation and ongoing support, we provide the expertise you need to succeed.

We understand the logistical challenges of implementing new machinery and are here to help you navigate them smoothly. Our goal is to ensure your operation runs efficiently, with minimal disruption and maximum benefit.

FAQ

What are the main benefits of Prodevco automation?

Increased efficiency, reduced labor costs, and improved precision are key benefits.

How does 3D programming enhance the process?

It creates accurate layouts, reducing rework and errors.

Is the investment in automation cost-effective?

Yes, the ROI from labor savings and increased output makes it worthwhile.

What support does Mac-Tech offer?

We provide comprehensive support from consultation to installation and beyond.

Can these systems handle different materials?

Absolutely, they’re designed for versatility and strength.

How does automation affect material handling?

It reduces handling time, speeding up the entire production process.

Feel free to reach out to me directly for any questions or sales support. I’m here to help you explore the best solutions for your fabrication needs.

Get Weekly Mac-Tech News & Updates