As someone who grew up in the Midwest and has spent years working hand-in-hand with fabrication shops across Wisconsin, I know what it means to get the job done right. I’m Kyle Bialozynski, Sales Executive at Mac-Tech, and I’ve seen firsthand how the right equipment can transform a shop’s bottom line. My approach is simple: listen to your needs, recommend solutions that make sense for your workflow, and stand by you long after installation. Let’s talk about how HSG Fiber Lasers can help you maximize your ROI and fuel your shop’s growth—without breaking the bank.

Unlocking Profit Potential with HSG Fiber Lasers: Real-World Results from Wisconsin Shops

Wisconsin shops are known for their ingenuity and work ethic, but even the best teams can be held back by outdated equipment. HSG Fiber Lasers are changing that equation. Several local shops that upgraded to HSG models have reported significant gains in both productivity and profitability. The combination of faster cutting speeds, lower operating costs, and minimal maintenance means you’re able to take on more jobs, deliver faster turnaround, and keep more of your hard-earned revenue.

HSG lasers deliver industry-leading performance at a fraction of the price of some high-profile European brands. For small to mid-sized shops, this is a game-changer. You get the advanced features and reliability you need to compete for larger contracts, while still maintaining a sensible investment. Shops using HSG have seen ROI in as little as 12 to 18 months, thanks to reduced downtime and increased throughput.

Choosing the Right HSG Model for Your Shop’s Workflow and Volume

Selecting the best laser for your operation depends on your specific needs—material thickness, volume, and space constraints all come into play. For high-mix, low-volume shops, the HSG G3015X offers flexibility and compact footprint, making it ideal for job shops and smaller production runs. If your workflow demands higher throughput or you regularly cut thicker materials, the HSG G4020H Pro gives you the power and speed to handle heavy-duty jobs with ease.

When I walk a shop floor, I pay close attention to your current process flow and where bottlenecks occur. HSG’s modular design options, such as automatic shuttle tables and integrated loading systems, can be tailored to your assembly process. This minimizes material handling and keeps your team focused on value-added work. We’ll work together to match the right machine and options to your production goals, ensuring you get the most out of every square foot of your facility.

Accelerating Production and Reducing Downtime through Advanced Laser Technology

Downtime is costly, and nobody wants to be stuck waiting for service or parts. HSG Fiber Lasers are engineered for reliability, with robust components and user-friendly controls that keep your team moving. Compared to older CO2 lasers, HSG’s fiber technology reduces both maintenance needs and energy consumption by up to 50%. That means more uptime, lower utility bills, and less time spent troubleshooting.

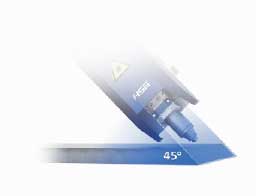

Features like auto-focus cutting heads and intelligent nesting software further streamline your workflow. These technologies reduce setup times, optimize material usage, and allow for rapid changeovers between jobs. Whether you’re cutting mild steel, stainless, or aluminum, HSG lasers deliver consistent results with less operator intervention, freeing up your skilled staff for more complex tasks.

HSG TS2 HIGH SPEED TUBE FIBER LASER CUTTING MACHINE

HSG 3015H 12KW

Enhancing Cut Quality and Versatility to Win More Local Contracts

Winning new business often comes down to quality and turnaround. HSG Fiber Lasers produce clean, burr-free edges with tight tolerances, giving your shop a reputation for excellence. The high-speed linear motors and advanced beam delivery systems mean you can handle intricate geometries and thicker materials with confidence.

Versatility is another key advantage. With the right HSG model, you can cut a wide range of materials and thicknesses without lengthy setup changes. This flexibility allows you to bid on a broader range of projects, from precision parts to heavy structural components, and deliver on-time for your customers. The result is more satisfied clients, more repeat business, and a stronger position in the Wisconsin manufacturing market.

Partnering with Mac-Tech for Personalized Support and Seamless Integration

Purchasing a new laser is a major decision, but you don’t have to go it alone. At Mac-Tech, we pride ourselves on offering more than just equipment—we provide ongoing support, training, and integration services tailored to your unique operation. From the initial site assessment to post-installation support, I’ll be there to ensure your HSG Fiber Laser is set up for success.

We understand Wisconsin shops because we work with them every day. Our local service team responds quickly, and our training programs are designed to get your team up to speed fast. Whether you need help with workflow optimization, software integration, or preventive maintenance, we’re committed to your long-term success.

FAQ

What makes HSG Fiber Lasers more cost-effective than other brands?

HSG delivers high performance and durability without the premium price of some European brands, offering a faster return on investment.

Can HSG lasers handle a variety of materials and thicknesses?

Yes, HSG models are versatile and can cut mild steel, stainless, aluminum, and more, with quick adjustments for different thicknesses.

How does HSG equipment reduce downtime?

Fiber technology, robust components, and local support mean less maintenance and quicker fixes, keeping your shop running.

What is the typical ROI timeline for an HSG Fiber Laser?

Most Wisconsin shops see payback within 12 to 18 months, depending on volume and workflow efficiency.

Does Mac-Tech provide training and integration support?

Absolutely. We offer hands-on training and help integrate the new laser into your existing processes for a smooth transition.

Is there a model that fits small shop spaces?

Yes, the HSG G3015X is compact and ideal for shops with limited floor space or needing flexible production capabilities.

What about service and parts availability?

Mac-Tech stocks common parts locally and our service team is based in Wisconsin, so help is always nearby.

If you have questions about how HSG Fiber Lasers could fit your shop, or want to see a demo, I’m here to help. There’s no pressure—just straightforward advice and Midwest service you can count on. Feel free to reach out by phone or email, and let’s see how we can boost your shop’s productivity together.

Get Weekly Mac-Tech News & Updates