With over three decades of expertise in delivering premium fabrication solutions, Mac-Tech stands at the forefront of innovation for metalworking shops throughout Illinois. Recognized for an unwavering commitment to quality and service, Mac-Tech continually sources and supplies the latest upgrades that breathe new life into legacy equipment. Among the most impactful investments for fabrication shops are advanced clamping upgrades for older hydraulic press brakes—a strategic move for those seeking to boost productivity, improve part quality, and extend the lifespan of existing assets.

Boost Productivity with Quick-Change Hydraulic Clamping Systems

Quick-change hydraulic clamping systems are revolutionizing the workflow of Illinois manufacturers operating legacy press brakes. These systems, such as the industry-leading Wila and Wilson Tool hydraulic clamps, are designed to fit a broad range of older press brake models. Their ability to rapidly secure and release tooling translates to significant reductions in changeover times, making them ideal for high-mix, low-volume production environments.

The integration of quick-change clamps minimizes manual intervention, reducing the risk of operator error and enhancing workplace safety. Shops benefit from a notable increase in daily throughput, as operators can switch between bending jobs in a matter of minutes rather than hours. This efficiency not only maximizes machine utilization but also accelerates project delivery, positioning shops to take on more business with confidence.

Enhance Precision and Repeatability with Advanced Tool Alignment Solutions

Precision and repeatability are critical for fabricators working with complex or high-tolerance parts. Advanced tool alignment solutions, such as laser-guided or mechanically indexed clamping rails, ensure dies and punches are perfectly positioned every time. These upgrades are compatible with a wide variety of older hydraulic press brakes and can be retrofitted with minimal disruption to daily operations.

By guaranteeing consistent tool alignment, these systems help reduce scrap rates and rework costs, leading to improved material yield and higher-quality finished products. For industries such as aerospace, automotive, or medical device manufacturing, where repeatability is paramount, these upgrades deliver measurable ROI. Mac-Tech’s team of experts provides full support from initial assessment to installation, ensuring seamless integration into existing workflows.

ERMAK EVOIII 3760-175

- Ermak EvoIII 3760-175 (193 Ton x 12’)

- 7-Axis: Y1, Y2, X, R, Z1, Z2, X-Prime (+/-3.94”)

- Delem 66Touch CNC Control, 17”

- CNC Motorized Crowning

- Precision Tooling Package

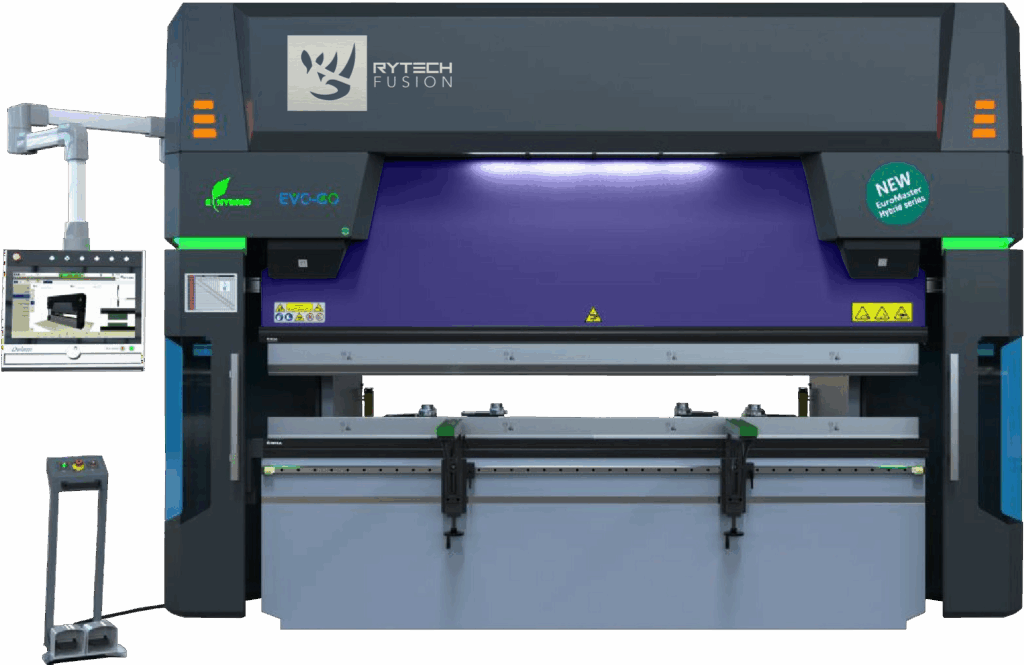

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Maximize Uptime with Durable, Low-Maintenance Clamping Components

Downtime is a major concern for any fabrication business. Upgrading to modern, wear-resistant clamping components—such as hardened steel clamps with self-lubricating bushings—can dramatically extend service intervals and reduce maintenance overhead. These components are engineered for longevity, withstanding the demanding cycles of heavy-gauge bending and high-production runs.

Mac-Tech sources only the most robust clamping solutions, offering clients peace of mind and a lower total cost of ownership. The company’s service team provides ongoing maintenance support, ensuring that every upgraded system continues to perform at peak efficiency. With less time spent on repairs and adjustments, shops can focus on what matters most: delivering quality parts on schedule.

Achieve Faster Setup Times with Automated Clamping Upgrades

Automated clamping upgrades, including CNC-controlled hydraulic clamping systems, are transforming the way operators set up and run older press brakes. These upgrades enable the rapid, repeatable positioning and locking of tooling with the push of a button, drastically reducing manual setup times. For job shops with frequent part changeovers, this automation translates to faster throughput and greater scheduling flexibility.

Ideal for both short and long production runs, automated clamping can be integrated with existing press brake controls or operated as standalone systems. Mac-Tech specializes in tailoring these solutions to each customer’s specific requirements, providing training and technical support to maximize the benefits of automation. The result is a more agile, responsive fabrication operation ready to compete in today’s fast-paced market.

Increase Bending Versatility with Universal Clamping Adaptations

Universal clamping adaptations open up a world of possibilities for shops running older hydraulic press brakes. By enabling compatibility with a wide range of tooling styles—including European, American, and custom profiles—these adaptations allow fabricators to tackle a broader spectrum of bending applications without investing in a new machine.

This upgrade is particularly valuable for contract manufacturers and job shops serving diverse industries. With universal clamping, operators can quickly switch between tooling types to accommodate unique part geometries or material requirements. Mac-Tech’s experienced team assists with selection, installation, and calibration, ensuring every adaptation delivers maximum versatility and return on investment.

Frequently Asked Questions

What types of press brakes are compatible with these clamping upgrades?

Most hydraulic press brakes, including legacy models from leading manufacturers, can be retrofitted with the clamping solutions Mac-Tech offers. Compatibility is confirmed during the initial assessment.

How long does installation typically take?

Installation time varies by upgrade type and machine condition but is generally completed within one to two business days with minimal disruption to production.

Are these upgrades covered by a warranty?

Yes, all clamping upgrades supplied and installed by Mac-Tech include manufacturer warranties and optional extended service agreements.

Can Mac-Tech assist with operator training after installation?

Absolutely. Mac-Tech provides comprehensive operator training to ensure safe, efficient use of all upgraded systems.

Is there a trade-in program for old tooling or clamping components?

Mac-Tech offers trade-in options and credit toward new clamping upgrades, depending on the condition and type of existing components.

How do these upgrades impact maintenance requirements?

Upgraded clamping systems are designed for durability and ease of maintenance, resulting in fewer service interventions and lower overall maintenance costs.

Optional: For more info: 888-MAC-9555, or find Mac-Tech on LinkedIn.

Get Weekly Mac-Tech News & Updates