Introduction to Servo Controls in Roll Forming

As someone who’s spent years helping shops modernize their production lines—from roofing to architectural fabrication—I’ve seen firsthand how servo controls can transform roll forming efficiency. My journey from southern Chicago to Mac-Tech has provided me with a wealth of experience in understanding the unique needs of each shop floor. Servo controls are a game-changer, offering precise adjustments that improve repeatability and minimize downtime between coil changes.

Enhancing Efficiency: Real-World Success Stories

On the shop floors, I’ve witnessed the remarkable impact of servo-driven systems. For instance, a customer using a Stefa roll former significantly reduced coil change time by implementing servo controls. This not only increased their throughput but also improved product consistency. Such upgrades have shown a return on investment by enhancing quality and reducing labor costs, making them a smart choice for any forward-thinking operation.

Evaluating Machine Upgrades for Improved Throughput

When considering machine upgrades, it’s essential to evaluate the potential for increased throughput. Servo controls in roll formers, like those from Stefa, offer the precision needed to handle complex profiles with ease. By upgrading, shops can achieve a smoother workflow and better accommodate diverse production demands. The result is a more agile operation that can adapt to market changes swiftly.

Precision and Workflow Integration in Metal Forming

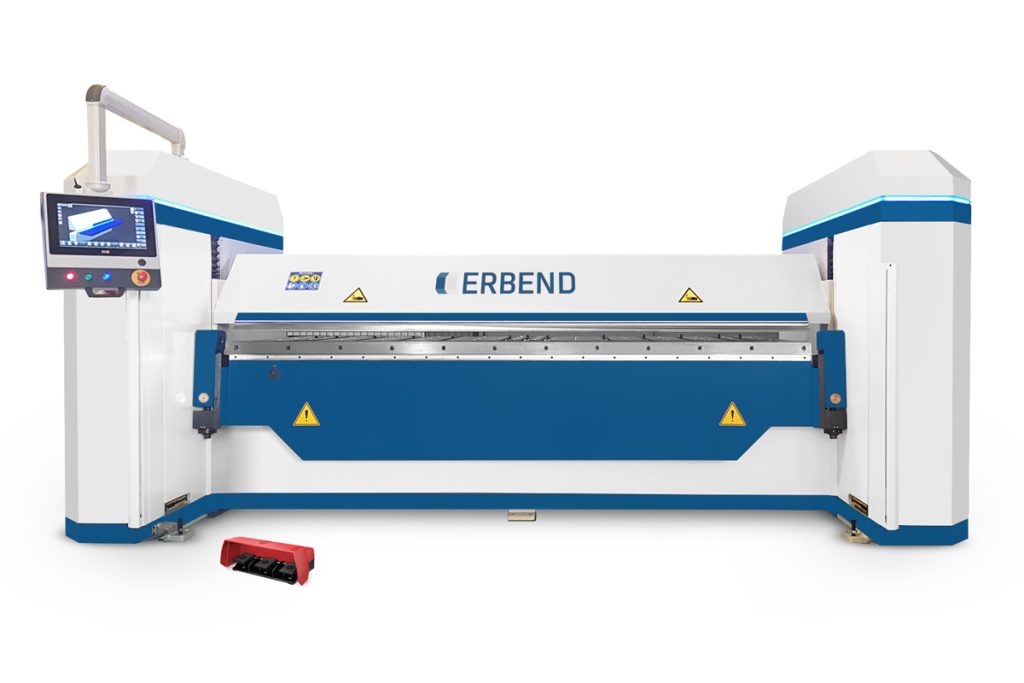

Precision is key in metal forming, and servo controls deliver just that. They integrate seamlessly into existing workflows, enhancing the precision of machines like Erbend folders and Akyapak benders. This integration reduces errors and ensures a higher quality output, which is crucial for maintaining a competitive edge in the industry.

ERBEND MFD STEEL SHEET FOLDING MACHINE

ERBEND MFE METAL FOLDING MACHINE

The Role of Automation in Slitting, Folding, and Shearing

Automation plays a vital role in modernizing slitting, folding, and shearing processes. By incorporating servo-driven systems, shops can automate adjustments and reduce operator intervention. This not only boosts efficiency but also enhances safety on the floor. Machines like Mac Shear benefit from these advancements, offering precise cuts with minimal manual oversight.

Conclusion: Making Informed Decisions for Optimal Performance

In the rapidly evolving landscape of metal forming, making informed decisions about upgrades and automation is crucial for optimal performance. Servo controls provide the precision, efficiency, and reliability needed to stay competitive. Whether you’re looking to enhance a roll former or integrate automation into your workflow, the benefits are clear.

FAQ Section

When is the right time to upgrade a roll former or folder?

Upgrading is ideal when you start noticing inefficiencies or increased maintenance costs. Evaluate the potential ROI and long-term savings from reduced downtime and improved quality.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer greater precision and energy efficiency compared to hydraulic systems, which can result in higher quality output and lower operational costs.

What’s the difference between a combi-beam and double folder?

A combi-beam can handle a variety of profiles without changing tools, while a double folder offers speed and efficiency for high-volume production.

What are signs a roll forming line is no longer cost-effective?

Increased maintenance costs, frequent downtime, and inconsistent product quality are key indicators that an upgrade is needed.

How can coil automation reduce operator requirements?

By automating coil changes and adjustments, you reduce the need for manual intervention, allowing operators to focus on quality control and other tasks.

What kind of maintenance schedule do panel benders need?

Regular inspections and preventive maintenance are crucial to ensure longevity and optimal performance of panel benders.

Can older shears be upgraded with safety and accuracy features?

Yes, many older shears can be retrofitted with modern safety guards and precision controls to enhance their performance and compliance with safety standards.

I’m always here to help you navigate the complexities of modernizing your production line. Feel free to reach out for a walkthrough, demo, or quote. With years of experience and a commitment to long-term customer success, I’m confident we can find the right solutions for your needs.

Get Weekly Mac-Tech News & Updates