In the ever-evolving world of metal fabrication, staying ahead of the curve is crucial for maintaining a competitive edge. As Mac-Tech celebrates its 40th anniversary, we reflect on the innovations that have revolutionized our industry. One such groundbreaking advancement is tube laser cutting technology. This article delves into how tube laser cutting is transforming metal fabrication, offering unmatched precision and efficiency. As a Regional Sales Executive at Mac-Tech, I am committed to providing solutions that meet our customers’ specific needs, ensuring they feel understood and supported.

Revolutionizing Metal Fabrication with Tube Laser Cutting

The metal fabrication industry has seen numerous technological advancements over the years, but few have been as transformative as tube laser cutting. This cutting-edge technology has redefined the way we approach metal fabrication, offering unparalleled precision and efficiency. At Mac-Tech, we have witnessed firsthand how tube laser cutting has revolutionized our clients’ operations, enabling them to achieve higher levels of productivity and quality.

Tube laser cutting technology allows for the precise cutting of metal tubes and profiles, which is essential for various applications, from automotive to construction. The ability to cut complex shapes and designs with minimal waste has made this technology a game-changer for metal fabricators. By integrating tube laser cutting into their processes, companies can reduce production times, lower costs, and improve overall product quality.

As we celebrate our 40th anniversary at Mac-Tech, we are proud to offer tube laser cutting solutions that meet the evolving needs of our customers. Our commitment to exceptional customer service and support ensures that our clients can fully leverage the benefits of this revolutionary technology. Whether you are looking to enhance your existing operations or explore new possibilities, tube laser cutting is a powerful tool that can help you achieve your goals.

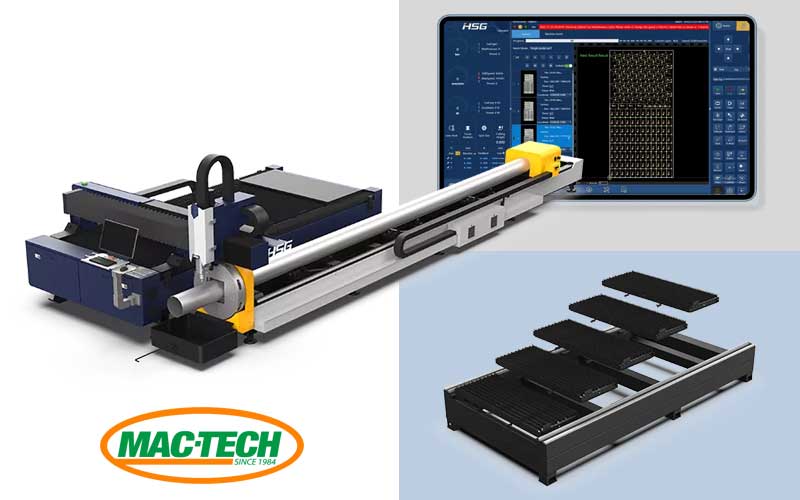

HSG CB Series

Sheet & Tube Cutting in One Machine

Compact. Capable. Cost-Saving.

When you need maximum performance with minimal footprint, the HSG CB Series…

R2-High-speed Tiny Tube Laser Cutting Machine

- Follow-up support for high precision

- Efficient multi-load loading

- Chuck jumping for short trailings

- Intelligent Bus operating System

The Unmatched Precision of Tube Laser Cutting Technology

One of the most significant advantages of tube laser cutting technology is its unmatched precision. Traditional cutting methods often struggle to achieve the same level of accuracy, especially when dealing with complex shapes and intricate designs. Tube laser cutting, on the other hand, uses advanced laser technology to deliver precise cuts with minimal deviation, ensuring that every piece meets exact specifications.

This precision is particularly beneficial for industries that require high levels of accuracy, such as aerospace, automotive, and medical device manufacturing. By utilizing tube laser cutting, manufacturers can produce components that meet stringent quality standards, reducing the risk of defects and improving overall product reliability. The ability to achieve such precision also opens up new possibilities for design and innovation, allowing companies to create more complex and sophisticated products.

At Mac-Tech, we understand the importance of precision in metal fabrication. Our tube laser cutting solutions are designed to deliver the highest levels of accuracy, helping our clients achieve their production goals with confidence. By investing in this advanced technology, you can ensure that your products meet the highest standards of quality and performance, setting your business apart from the competition.

Why Tube Laser Cutting is a Game-Changer for Fabrication

Tube laser cutting is not just a technological advancement; it is a game-changer for the metal fabrication industry. One of the key reasons for this is its ability to significantly reduce production times. Traditional cutting methods often require multiple steps and manual intervention, leading to longer lead times and higher labor costs. Tube laser cutting streamlines the process, allowing for faster and more efficient production.

Another major advantage of tube laser cutting is its versatility. This technology can handle a wide range of materials and thicknesses, making it suitable for various applications. Whether you are working with stainless steel, aluminum, or other metals, tube laser cutting can deliver precise and consistent results. This versatility allows fabricators to take on a broader range of projects, expanding their capabilities and market reach.

Finally, tube laser cutting offers significant cost savings. By reducing material waste and minimizing the need for secondary operations, this technology can lower overall production costs. Additionally, the increased efficiency and precision of tube laser cutting can lead to higher yields and fewer defects, further enhancing profitability. At Mac-Tech, we are committed to helping our clients realize these benefits, providing solutions that drive growth and success.

FAQ

What materials can be cut using tube laser cutting technology?

Tube laser cutting technology is versatile and can handle a wide range of materials, including stainless steel, aluminum, carbon steel, and more.

How does tube laser cutting improve production efficiency?

Tube laser cutting streamlines the cutting process, reducing the need for multiple steps and manual intervention. This leads to faster production times and lower labor costs.

Is tube laser cutting suitable for complex shapes and designs?

Yes, tube laser cutting excels at cutting complex shapes and intricate designs with high precision, making it ideal for various applications.

What industries benefit the most from tube laser cutting technology?

Industries such as aerospace, automotive, construction, and medical device manufacturing benefit significantly from the precision and efficiency of tube laser cutting.

How does tube laser cutting reduce material waste?

Tube laser cutting uses advanced laser technology to make precise cuts, minimizing material waste and optimizing the use of raw materials.

Can tube laser cutting handle different thicknesses of materials?

Yes, tube laser cutting is capable of cutting materials of varying thicknesses, providing consistent and accurate results across different projects.

What are the cost benefits of using tube laser cutting technology?

Tube laser cutting reduces production costs by minimizing material waste, lowering labor costs, and increasing overall efficiency and yield.

As we continue to innovate and push the boundaries of metal fabrication, tube laser cutting stands out as a transformative technology that offers unmatched precision, efficiency, and versatility. At Mac-Tech, we are dedicated to providing our clients with the best solutions to meet their unique needs. If you are looking to revolutionize your metal fabrication processes or need expert advice on the right equipment for your operations, I am here to help. Reach out to me for personalized support and discover how tube laser cutting can elevate your business to new heights.

Get Weekly Mac-Tech News & Updates