In the field, I keep seeing the same pattern on coil-fed forming and panel work: the machine can run fast, but the shop cannot feed it consistently. The real bottlenecks are usually coil loading delays, inconsistent straightening, manual squaring, and long first-piece approvals that create scrap and rework. When labor is tight, those frictions turn into schedule volatility and unsafe handling because people rush lifts, threading, and cutoffs to catch up. A payback model that ignores those realities will always overpromise, so I build ROI around what actually happens between coil entry and a finished, shippable part.

Establishing Baseline Coil-Fed Line Performance and Cost per Part

Most shops tell me their line rate, but the truth is in effective rate: how many good parts ship per hour after changeovers, coil swaps, downtime, and inspection holds. I start by separating run time from touch time, because a coil line that looks automated still gets dragged down by manual threading, hand measurements, and rework loops. If you do not baseline those losses, you cannot trust a payback.

Baseline inputs that make ROI real:

- Average run length by part family and gauge

- Changeover time, first-piece approval time, and coil change time

- Actual scrap rate by cause: setup, camber, bow, length error, bend angle drift

- Labor touch points per shift: forklift moves, threading, stacking, measuring

- Overtime, missed ship penalties, and expediting frequency

I convert those into cost per good part, not cost per machine hour. That means material loss, labor constraints, and unplanned handling are treated as primary drivers, because they usually outweigh the theoretical speed of the roll former, folder, or shear. Once we have a truthful baseline, we can test what improvements actually move the needle in your shop, not a brochure scenario.

ERMAK – HVR

Building a Real-World ROI Model for Folding, Slitting, Shearing, and Rolling Automation

The ROI model that holds up in real shops is a throughput and stability model, not a simple labor removal model. Automation often does not eliminate headcount; it frees the same people to run longer lights-out windows, keep upstream and downstream steps fed, and stop paying for preventable scrap. I model payback using conservative assumptions: one constrained position you cannot reliably staff, scrap you can document today, and the changeover time you can measure with a stopwatch.

ROI drivers I use most often:

- Labor availability and the true cost of overtime and turnover

- Changeover frequency driven by high mix and short run lengths

- Scrap and rework tied to setup variation and inconsistent feeding

- Scheduling stability from predictable cycle time and reduced stops

- Safety risk reduction from less manual coil handling and fewer pinch-point interventions

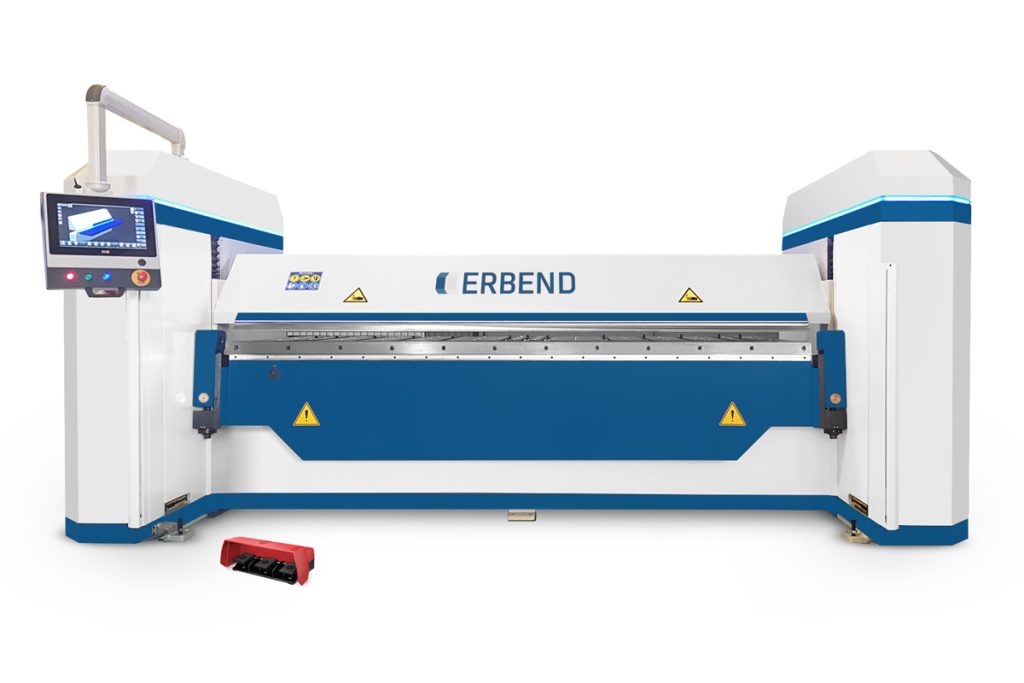

For folding and panel production, the payback often comes from setup compression and repeatability, especially with an Erbend folder or a panel bender where the control and backgauging remove the guesswork across long parts. For slitting and shearing, the biggest wins are consistent straightening, accurate length control, and faster coil-to-coil transitions using integrated coil systems and a Mac Shear solution that is sized to how you actually run, not how you wish you ran.

Quantifying Throughput and Precision Gains from Servo Feeds, Controls, and Tooling Upgrades

Servo feeds and modern controls do two things that matter for ROI: they reduce variation and they cut recovery time when something changes. If your operators are chasing length, fighting camber, or compensating for inconsistent coil edges, you are paying for micro-stops and scrap that never shows up in machine cycle time. A servo-driven feed and a properly matched straightener make the line predictable, and predictability is what lets you schedule with confidence.

Where precision gains translate into dollars:

- Length accuracy reduces downstream fit-up and rework

- Repeatable bends cut first-piece iterations on folders and panel benders

- Stable feed reduces tool wear from uneven loading and mis-hits

- Less measuring and manual correction reduces touch time per part

Tooling upgrades also matter, especially in forming and rolling where edge condition and bend radius stability drive scrap. If you are rolling with Akyapak equipment, for example, matching tooling and controls to your material range reduces the operator compensation that creates inconsistency from shift to shift. The tradeoff is upfront cost versus staged upgrades, but even staged improvements can pay back quickly when they remove the biggest source of variation first.

Material Flow and Changeover Optimization from Coil Entry to Finished Parts

A lot of payback is sitting at the front end of the line where coil entry is slow, unsafe, and inconsistent. If the coil car, uncoiler, threading table, straightener, and feeder are not treated as a system, you get stop-start production and the operator becomes the control loop. Integrating coil systems so the material is presented consistently into the machine is often the simplest way to reduce both downtime and scrap.

Changeover and flow improvements that drive fast payback:

- Quick-load coil cars and guided threading to reduce non-cut time

- Recipe-driven feed and straightener settings for repeatable setups

- Standardized tooling and gauging strategy for part families

- Better outfeed and stacking to prevent dents, bowing, and rework

For high-mix panel work, the biggest leverage is reducing changeovers so short runs stop killing your day. Panel benders and modern folders can make high-mix profitable because they shift setup from manual fiddling to controlled, repeatable positioning. If you want to evaluate configurations and practical upgrade paths, I often point teams to the Mac-Tech storefront and application categories at https://shop.mac-tech.com/ to align equipment choices with real part flow.

Safety, Scrap, and Maintenance Impacts that Shift Payback Timelines

Safety is not a soft benefit when it determines whether you can keep a line running without constant slowdowns and interventions. Manual coil handling, pinch points at threading, and unstable outfeed stacking force operators to take risks or stop the line, and both outcomes cost money. When a shop improves safety with better coil handling and guarding, the payback shows up as fewer stoppages, fewer incidents, and less reluctance to run at optimal pace.

Scrap is the other payback accelerator that many models underweight. When you reduce setup scrap and stabilise the process, you also reduce hidden scrap like downgraded parts, sorting time, and the downstream assembly adjustments that get written off as normal. Maintenance also shifts because consistent feeding and correct straightening reduce shock loads, tool chipping, and premature wear, which improves uptime and makes preventive planning possible.

If you are also considering production data capture and workflow coordination, Vayjo can be a practical supporting piece to connect quoting, scheduling, and job tracking so the gains from automation show up clearly in operating metrics: https://vayjo.com/. The key is to use that visibility to validate assumptions and keep improving after the equipment is installed.

Next Steps for Selecting and Implementing a Coil Automation Upgrade Plan

The best upgrade plan is the one that removes your top constraint first, even if that means you do not buy a full integrated line on day one. Some shops should start with coil handling and straightening because that stabilizes everything downstream; others need servo feed and controls first because length and repeatability are the root cause of scrap. I prefer staged upgrades when cash flow or layout limits are real, and full integration when labor scarcity and high volume demand immediate throughput stability.

Decision criteria I use to pick the right path:

- Your run length distribution and how often you change over

- The tightest tolerance on length, hole-to-edge, or bend angle

- Coil width, gauge range, and material type variability

- Available floor space and how many times material is rehandled

- Safety exposure points during loading, threading, and outfeed

Implementation is where ROI is won or lost, so I plan for training, setup sheets, spare wear parts, and a defined acceptance test tied to your baseline metrics. We also map the material flow so the new capability does not create a downstream bottleneck at packaging, staging, or shipping. If you want a starting point for configurations, options, and accessories, https://shop.mac-tech.com/ is a straightforward way to compare what fits your process before we finalize a proposal.

FAQ

When should I upgrade a roll former, folder, shear, or coil line?

When changeovers, scrap, and staffing are limiting shipped parts per shift more than machine speed is, the upgrade will usually pay back faster than adding labor.

Servo vs hydraulic forming, what is the real tradeoff?

Servo systems typically win on repeatability, control, and setup reduction, while hydraulic can be cost-effective for certain force-heavy tasks with less demand for precision and rapid changeover.

How do I reduce setup time without buying a full new line?

Start with recipe-driven controls, standardized tooling, and coil handling that makes threading and straightening repeatable, then add servo feed or upgraded gauging where variation is coming from.

What coil handling improvements reduce labor and improve safety the most?

Coil cars, guided threading, proper straightener sizing, and safer outfeed/stacking reduce the number of manual interventions and forklift moves per shift.

Are panel benders worth it for high-mix production?

Yes when you run many short jobs and your bottleneck is skilled bending labor or setup time, because repeatable positioning and automated sequences compress changeovers.

What maintenance points should I plan for on a coil-fed line?

Plan around straightener rolls, feed rollers, tooling wear, lubrication, and alignment checks, because inconsistent material presentation is a common root cause of premature wear and downtime.

What information do you need from me to size a system accurately?

Send profiles or prints, material type, gauge range, coil width and OD/ID, target parts per hour, and your run length and changeover pattern so I can model payback with your realities.

Contact me for a walkthrough, demo, or upgrade consultation at pat@mac-tech.com or 414-232-7929, and you can also explore coil and fabrication solutions at https://shop.mac-tech.com/.

Get Weekly Mac-Tech News & Updates