I’m Joe Ryan, President of Mac-Tech (joe@mac-tech.com, 414-477-8772). My perspective on Industry 4.0 is shaped by more than just my passion for metal fabrication. With a background in finance and leadership, I’m always looking for ways to align strategic vision with tangible returns, focusing on long-term growth, efficiency, and stability. By layering the principles of “Preparing for Industry 4.0: Future-Proofing Your Fabrication Business” with the lessons I’ve learned in the world of finance, I’ve built a framework that guides how we approach business opportunities at Mac-Tech—always putting your bottom line at the forefront of innovation.

My Vision: Driving Strategic Growth Through Innovation

I’ve learned throughout my career that strategy is nothing without execution. My goal is to empower our clients with the right tools and insights that spark impressive transformations. Industry 4.0 isn’t about piling on the newest electronics or trendy software; it’s about leveraging data to make better decisions and calibrating operations for maximum impact. My finance background tells me that any innovation needs to align with metrics that matter: cost reduction, time-to-market, and net returns.

A pivotal lesson I’ve carried with me—whether working on a fixed income desk or leading Mac-Tech—is that growth must be guided by sustainable practices. In the realm of metal fabrication, this translates to adopting machines and processes that enable continuous improvement without depleting cash flow. By integrating specialized software, automation, and lean methodologies, we can place our clients at the forefront of operational excellence.

With Industry 4.0, the next wave of investments will revolve around real-time analytics, predictive maintenance, and agile supply chain models. Having led teams where every operational move was measured against financial benchmarks, I bring that same discipline to Mac-Tech’s strategies. We don’t just sell equipment—we enhance productivity and open new pathways for scaling your business in ways that make financial sense.

My commitment to driving innovation remains anchored by accountability and a clear path to ROI. Whether helping a small fabricator integrate a new laser-cutting machine or guiding a larger enterprise through a full-scale robotic automation overhaul, my vision revolves around bridging the gap between technology adoption and the bottom line.

TL FOUR-CHUCK HEAVY-DUTY TUBE FIBER LASER CUTTING MACHINE

- Four Chuck Structure

- Automatic Loading and Unloading

- HSG-X Bus Control System

- Tube Splicing Technology

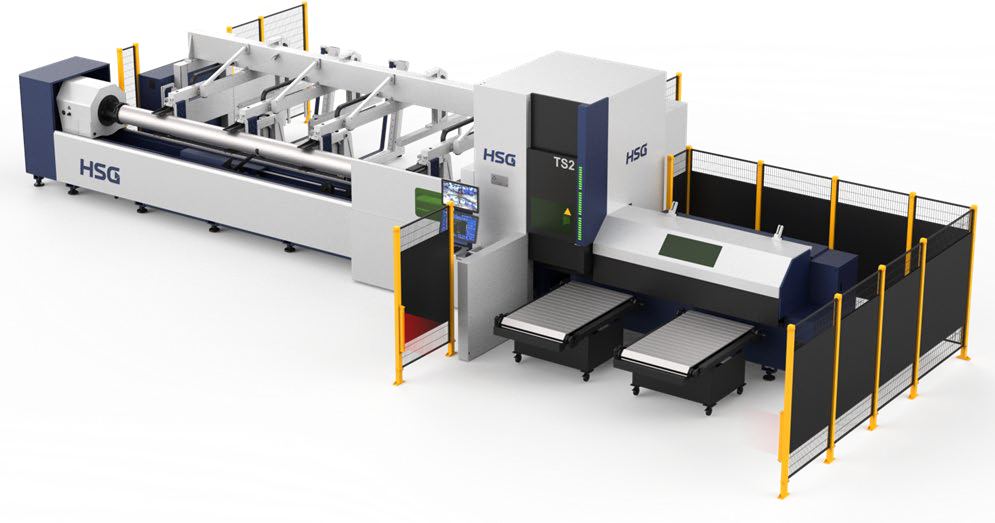

HSG TS2 V2.0 TUBE LASER CUTTING MACHINE

High-Speed Precision for Advanced Tube Processing

The HSG TS2 V2.0 delivers unmatched efficiency and accuracy in tube laser cutting. Equipped with a 6kW…

Maximizing ROI with Advanced Metal Fabrication Systems

As a leader with a financial background, I firmly believe ROI is more than a buzzword. It represents the potential for operational efficiency to pay dividends well into the future. When we talk about advanced metal fabrication systems—be it press brakes, laser cutters, or automated bending solutions—real ROI hinges on streamlined processes, reduced labor costs, and improved cycle times.

Industry 4.0 enables these systems to connect seamlessly, sharing data that can be translated into tangible business insights. Through real-time monitoring and lean analysis, we can minimize operational bottlenecks. My experience in analyzing futures has shown me the value of forward-looking data: if we can anticipate market shifts and production needs accurately, we can hedge risks and position our clients for consistent returns.

Clients regularly ask me: “Is the investment worth it?” My reflex, honed in finance, is to crunch the numbers, verifying whether an equipment upgrade or new software integration will genuinely enhance productivity. Scalability is another critical factor. If your business rapidly outgrows the initial setup, you risk incurring extra costs. Our advanced systems at Mac-Tech are designed with modular expansion in mind, allowing you to scale operations with minimal disruptions.

ROI is about more than raw numbers, though. It’s also about market positioning and being a step ahead of competitors. Investing in advanced fabrication solutions from Mac-Tech means you’re not just upgrading your workshop—you’re evolving your entire approach to manufacturing, ensuring that returns continue to flow in as markets evolve.

How Mac-Tech Shapes Market Growth and Future Business Value

Mac-Tech’s role in the metal fabrication market extends beyond being an equipment supplier. My focus on business fundamentals, shaped by years in leadership and finance, ensures that our solutions integrate market expansion and profit potential. We encourage clients to look at the big picture: how does a new machine or process feed into a larger strategy of entering new markets or growing existing ones?

Importing machinery and raw materials can be a complex process with varying costs, but it’s central to many of our clients’ expansion plans. Thanks to my background in financial markets, I can help customers navigate currency fluctuations, long-term contracts, and strategic sourcing. Balancing risk and return is the name of the game here. We work closely with you to forecast costs and secure stable supply chains without sacrificing margins.

Future business value often stems from sustainability and adaptability. When we talk about Industry 4.0, we’re envisioning production lines that adapt to shifting demands, robotic cells that reduce human error, and digital platforms that offer real-time data visualization. These upgrades are no longer optional—they’re mandatory for companies looking to solidify their position for years to come. When we deploy such solutions, it’s not just a hardware sale; it’s an investment in your company’s future value.

Of course, growth can’t be forced—it must be guided by strategy, resources, and market demand. My finance experience keeps me vigilant about ensuring that every new project has a solid business case. From carefully mapping out financing options to analyzing total cost of ownership, we tailor Mac-Tech’s solutions to align with your strategic trajectory. The result is a more resilient operation that’s primed for market growth, ready to capitalize on every opportunity.

FAQ

• How can I calculate the true cost-benefit of investing in new technology?

I apply my background in finance to analyze everything from upfront costs to long-term operational gains, ensuring you have a clear picture of your future returns.

• Where do I start with scaling operations for Industry 4.0?

We begin with an evaluation of your current processes, identifying bottlenecks and areas for incremental improvements, before tailoring a progressive integration plan.

• Is automation the key to remaining competitive in tight markets?

Automation often reduces human error while increasing throughput, so it can be a strong strategic move. Still, I advise evaluating market demands to ensure you’re applying automation effectively.

• How do I manage risk when importing machinery from international markets?

My experience with futures and fixed income helps us plan for currency fluctuations and supply chain variances, allowing us to mitigate risk and maintain stable pricing.

• What ROI timeline should I expect when implementing Mac-Tech’s solutions?

That depends on factors like production volume, labor costs, and existing infrastructure—but we aim for a realistic roadmap that showcases returns as quickly as possible.

I appreciate you taking the time to learn more about how we future-proof fabrication through Industry 4.0. If you’re ready to explore the next steps, feel free to reach out to me at joe@mac-tech.com or 414-477-8772. Let’s discover how we can strategically grow your operation and position your business for robust, long-term success!

Get Weekly Mac-Tech News & Updates