Patrick O’Neill here—most know me as Pat. My journey started on the south side of Chicago, learning what it means to put the customer first in every job. That approach stuck with me as I moved into the world of metal fabrication, eventually landing at Mac-Tech. Every day, I work alongside roofing and fabrication businesses to help them get more out of their production lines, whether that means a simple upgrade or a complete overhaul. My job is to listen, understand your challenges, and bring the best solutions to the table—solutions that drive efficiency, quality, and profitability.

Harnessing Decades of Coil Punching Expertise to Drive Efficiency Gains

When it comes to coil punching lines, there’s no substitute for experience. Over the years, I’ve seen how a well-maintained line can be the heartbeat of a fabrication shop, driving higher throughput and tighter tolerances. At Mac-Tech, we partner with manufacturers to evaluate their current processes and identify opportunities for improvement. Whether you’re running folders, shears, slitters, decoilers, downspout roll formers, or panel benders, the right maintenance practices are critical—not just for uptime, but for maintaining the precision your customers demand.

A customer-first approach means I’m not just selling a machine; I’m invested in your long-term success. That’s why I focus on sharing proven best practices, from routine lubrication schedules to advanced diagnostics, ensuring your coil-fed production lines deliver consistent results day after day.

Evaluating Coil-Fed Production Lines for Maximum Output and Minimal Waste

Efficiency is more than speed—it’s about maximizing output while minimizing scrap and downtime. The first step is a thorough evaluation of your existing coil-fed line. Are your slitters producing clean, burr-free edges? Is your decoiler keeping up with your folder or roll former, or is it causing bottlenecks? I help customers compare equipment options side by side, looking at real-world metrics like cycle times, material utilization, and labor requirements.

Automation is a game-changer for many shops. Upgrading to automated feeding and stacking systems can reduce manual handling, improve operator safety, and ensure repeatable quality. I’ve worked with shops that cut their labor costs by 30% and boosted throughput by integrating the right coil handling equipment. Every line is unique, so the key is matching technology to your production goals.

Upgrading Equipment: Proven Strategies for Enhanced Metal Folding and Roll Forming Performance

When considering an upgrade, focus on where you can achieve the greatest return. Servo-driven folders, for instance, offer unmatched speed and accuracy compared to older hydraulic models. With tighter tolerances and faster setups, these machines can transform panel production, especially for architectural and standing seam roofing.

Roll formers are another area where technology pays off. Modern lines offer quick-change tooling and integrated punching, allowing for rapid transitions between profiles. For shops handling a variety of products, this flexibility is invaluable. I often recommend modular roll forming systems that can grow with your business, protecting your investment as your needs evolve.

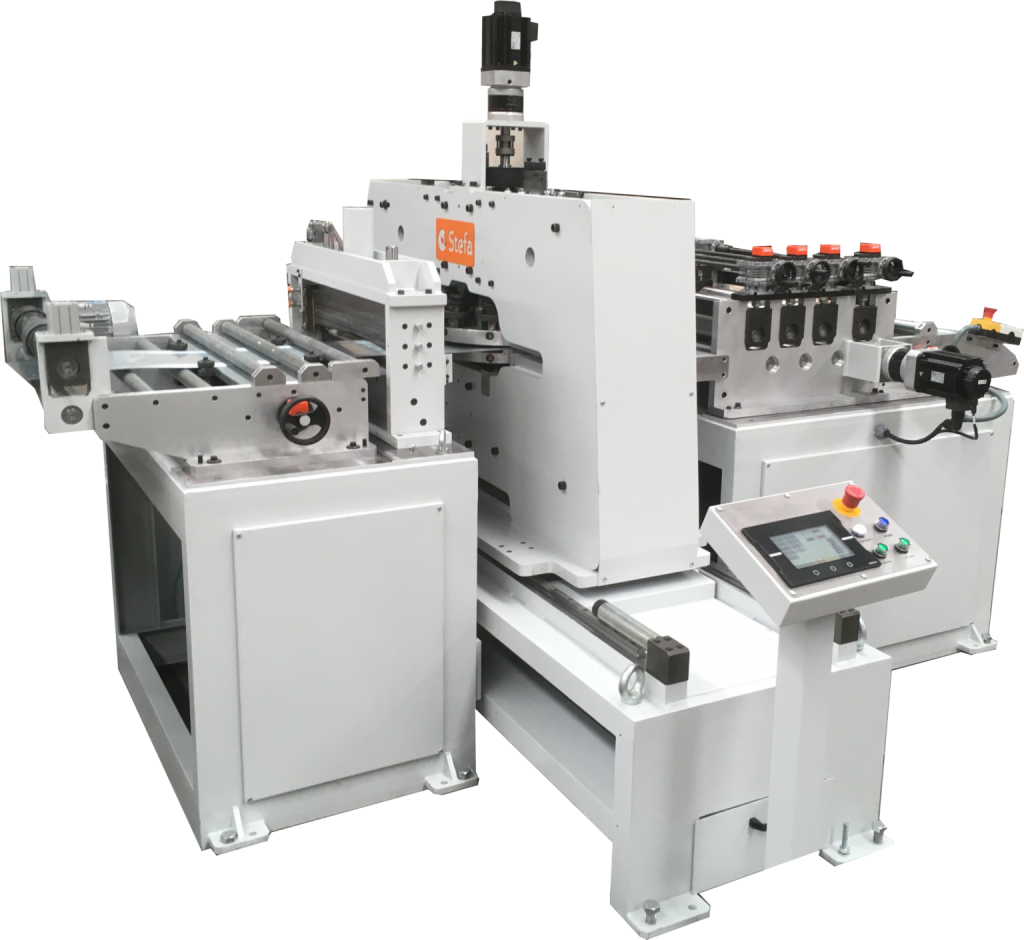

COIL PUNCHING MACHINE

Addressing Critical Fabrication Needs: Slitting, Forming, Folding, and Speed Optimization

Every fabrication shop faces unique challenges: some need high-speed slitting for large coil runs, while others prioritize complex folding for custom architectural panels. I help customers break down their workflow, identifying where upgrades or maintenance can deliver immediate gains.

For example, a customer struggling with inconsistent slitting quality benefited from a precision slitter upgrade, reducing waste and rework. Another shop improved its folding accuracy by switching to a combi-beam folder, handling both straight and radius bends with a single machine. Speed optimization isn’t just about running faster—it’s about running smarter, with coordinated equipment that eliminates bottlenecks and maintains quality at every step.

Implementing Maintenance Protocols that Sustain Peak Productivity and Machine Longevity

Proactive maintenance is the foundation of any high-performing coil punching line. I work closely with customers to develop tailored maintenance protocols, covering everything from daily inspections to scheduled component replacements. Simple steps—like monitoring oil levels, checking for wear on tooling, and calibrating sensors—can prevent costly breakdowns and extend machine life.

I also recommend digital maintenance tracking, allowing teams to log issues, schedule service, and access historical data. This transparency makes it easier to spot trends and address problems before they impact production. With the right protocols, shops can achieve near-continuous uptime and deliver on even the most demanding project timelines.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent downtime, rising maintenance costs, or struggling to keep up with customer demand, it’s time to evaluate your options. An upgrade is also worth considering if you need tighter tolerances, more profile flexibility, or want to reduce labor input. I’m always happy to walk through your current setup and provide an honest assessment.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer faster cycle times, more precise bends, and quieter operation. They’re ideal for shops needing high accuracy and frequent setup changes. While hydraulic folders are reliable, the efficiency gains with servo technology often justify the investment, especially for high-volume or architectural work.

What’s the difference between a combi-beam and double folder?

A combi-beam folder allows you to switch between different bending profiles without changing tooling, making it versatile for shops handling a variety of parts. Double folders can bend both up and down without flipping the sheet, which speeds up production and reduces handling. Choosing the right model depends on your product mix and production goals.

What are signs a roll forming line is no longer cost-effective?

Look for recurring breakdowns, excessive scrap, or long setup times. If your line struggles to meet current volume or quality standards, or if replacement parts are hard to source, it may be time to explore an upgrade. I can help you run the numbers and compare the total cost of ownership for new vs. legacy equipment.

Can Mac-Tech help with maintenance training and support?

Absolutely. We provide on-site training, troubleshooting support, and remote diagnostics for all major coil punching and fabrication equipment. Our goal is to empower your team to keep machines running at peak performance.

Ready to take your coil punching line to the next level? Whether you need a walkthrough, a live demo, or a detailed upgrade quote, I’m here to help. Reach out directly at pat@mac-tech.com or 414-232-7929—or use the form below to get started. Let’s build something great together.

Get Weekly Mac-Tech News & Updates