Over the years, I’ve been fortunate to work with incredible customers at Mac-Tech who trust me to guide them toward the best solutions for their metal coil handling needs. As VP of Sales, I’ve found my passion in using my deep experience in automation and precision fabrication to help businesses thrive. From the moment I first learned about Forstner’s state-of-the-art coil solutions, I knew they would be a game-changer for many of my customers, and I’m excited to share my approach on exactly how I help clients benefit from these innovative systems.

I Earn Trust by Listening to Coil Challenges

In my role, I believe trust begins with genuine empathy. When customers approach me, often their first concern is reliability—whether Forstner’s equipment can truly handle their production volume and unique coil specifications. I never jump into selling right away; instead, I spend time understanding the nuances of their operations, their pain points, and future growth plans. In my experience, people appreciate when you validate their challenges.

Once I understand their day-to-day struggles, I follow up with pointed questions about their existing systems, their current processes, and their end goals. It’s not uncommon to discover deeper issues—inefficiencies, staff training gaps, or dated technology that’s hampering their full potential. By clarifying these details, I gain a complete picture that allows me to address their concerns head-on.

My top priority is to reassure them they’re in good hands. I share real-world examples of customers who faced similar problems and how we resolved them. This credibility helps people see that I’m not just making a pitch; I’m genuinely committed to transforming their operational bottlenecks into streamlined, profitable workflows.

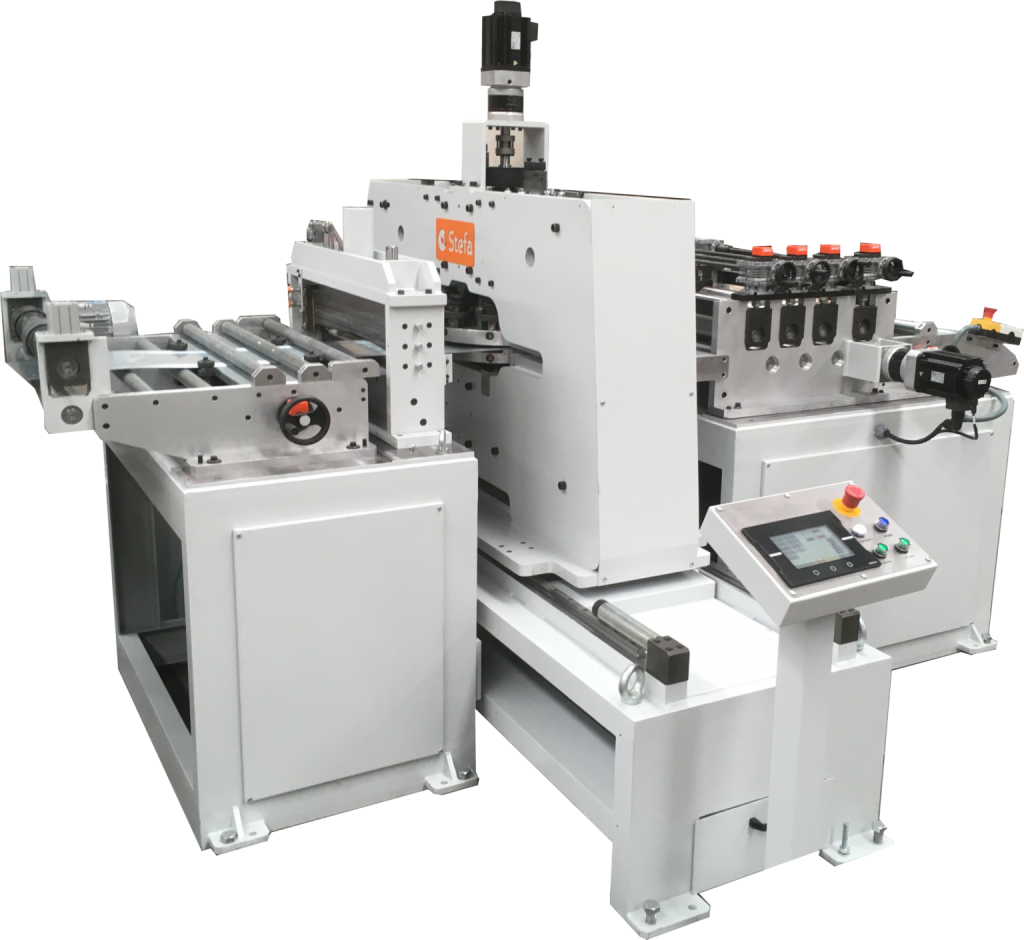

LISSMAC SMW 123

COIL PUNCHING MACHINE

I Personalize Solutions with Forstner’s Expertise

After identifying the specific challenges, I tap into Forstner’s extensive product range and capabilities. From precision decoilers to advanced sheet metal processing systems, there’s always a tool suited for a broad spectrum of production demands. My familiarity with Forstner’s lineup allows me to match clients with exactly what they need—nothing more, nothing less.

Once we narrow down the potential solutions, I tailor my recommendations based on production scale, coil width, material thickness, and goal timelines. In my opinion, there’s no one-size-fits-all fix. I showcase how certain Forstner features—like fully automated coil feeding or advanced edge-trimming systems—can optimize output for that customer’s environment.

At this stage, transparency is key. I walk my clients through each feature, the anticipated learning curve, and what resources they’ll need. It’s my job to ensure they have the clearest possible picture of how the solution will work in their facility. By setting realistic expectations, I maintain the trust I’ve worked hard to build.

I Collaborate Closely to Ensure Seamless Integration

Once my customers decide on a solution, I bring together key stakeholders—including our technical teams, Forstner’s support specialists, and sometimes external partners—to outline the rollout plan. In my experience, a successful installation relies on detailed cooperation from all sides. As the client’s main point of contact, I see it as my responsibility to coordinate every phase of the project.

Open communication keeps the process on track. We map out timelines, talk about potential challenges, discuss site preparations, and ensure the support staff is ready for any question that might arise. By having everyone aligned from the outset, we avoid costly delays and any surprises down the road.

Even after the solution is operational, I remain closely involved. I check in regularly to assess progress, troubleshoot if any issues crop up, and gather feedback on how things might be tweaked for even better performance. These ongoing collaborations make a huge difference, building a strong working relationship that lasts well beyond the initial sale.

I Prioritize Results to Maximize Client Satisfaction

Ultimately, what drives me is seeing the tangible outcomes my customers achieve. I’m convinced that a carefully chosen coil solution can spark exponential gains in efficiency, consistency, and profitability. That’s why I place so much emphasis on aligning Forstner’s technology with each client’s unique objectives.

I regularly review key performance metrics, comparing pre-installation benchmarks with the new, optimized workflows. This data-driven approach helps confirm that our chosen system is delivering on its promises. If it isn’t, I’ll step in and mobilize the necessary resources to make sure we reach the desired outcome.

Throughout this process, I never lose sight of the bigger picture: my goal is to build relationships that last. Every project is an opportunity to prove our value, not just in the short term, but as a long-term partner dedicated to each customer’s success. I’m always ready to adapt, refine, and enhance the solutions as production needs evolve.

FAQ

What makes Forstner’s metal coil solutions stand out from other brands?

Forstner is renowned for its advanced automation features and longstanding expertise in precision coil handling. These solutions are built for high-volume reliability, reducing downtime and increasing throughput.

How do you ensure the chosen solution truly meets my business needs?

I combine my firsthand knowledge of automated fabrication with a detailed assessment of your production goals. From there, I customize the solution to fit your specific requirements, ensuring optimal performance.

What kind of technical support can I expect post-sale?

Our collaboration doesn’t end once the equipment is installed. My team and I stay in close contact, offering training, troubleshooting, and ongoing maintenance support to maximize uptime.

How long does it typically take to integrate Forstner equipment into an existing production line?

Implementation timelines vary based on the complexity of your setup, but I’ll collaborate with all key stakeholders to map out a clear, efficient plan that minimizes disruptions to your operations.

Will I need specialized training to operate Forstner’s coil solutions?

Yes, but not to worry. We provide comprehensive on-site or remote training sessions. These sessions ensure your staff gains the necessary expertise quickly, so you can start seeing results right away.

Thank you for letting me share how I guide clients toward the right Forstner solutions. My goal is to help you optimize your coil-processing workflows and build a lasting partnership through attentive support. If you’re ready to explore how Forstner’s advanced technology can transform your operation, I invite you to reach out for a personalized consultation.

Get Weekly Mac-Tech News & Updates