After decades of working side-by-side with fabricators and roofing pros from southern Chicago to the heart of the Midwest, I’ve seen firsthand what it takes to keep a shop competitive. My career—built on listening, learning, and delivering practical solutions—brought me to Mac-Tech, where I help businesses transform their production lines with modern automation. Whether you’re a family operation or a multi-state fabricator, my customer-first approach means I’m always focused on your real-world challenges, not just pushing the latest machine. Let’s dive into how coil punching and cut-to-length (CTL) automation can revolutionize roofing production, eliminate bottlenecks, and set your shop up for lasting success.

Leveraging Decades of Expertise: Pat O’Neill’s Approach to Roofing Production Challenges

Every manufacturer faces unique hurdles—tight deadlines, evolving roof profiles, and the constant need to do more with less. My background covers everything from folders and shears to slitters, decoilers, and panel benders. I’ve spent years helping customers sort through options, compare technologies, and implement upgrades that actually move the needle. It’s not about selling a machine; it’s about finding the right fit to boost your bottom line and keep your crew safe and productive.

Identifying Bottlenecks: Evaluating Current Coil-Fed and Roll Forming Operations

The first step is an honest assessment of your current setup. Are operators manually punching holes or notching panels after forming? Are your CTL lines causing backup at the roll former? Too often, shops rely on legacy equipment that slows production, requires excessive handling, and introduces inconsistencies. By mapping out your process flow—from coil loading to finished panels—we can pinpoint exactly where delays and labor-intensive steps are holding you back.

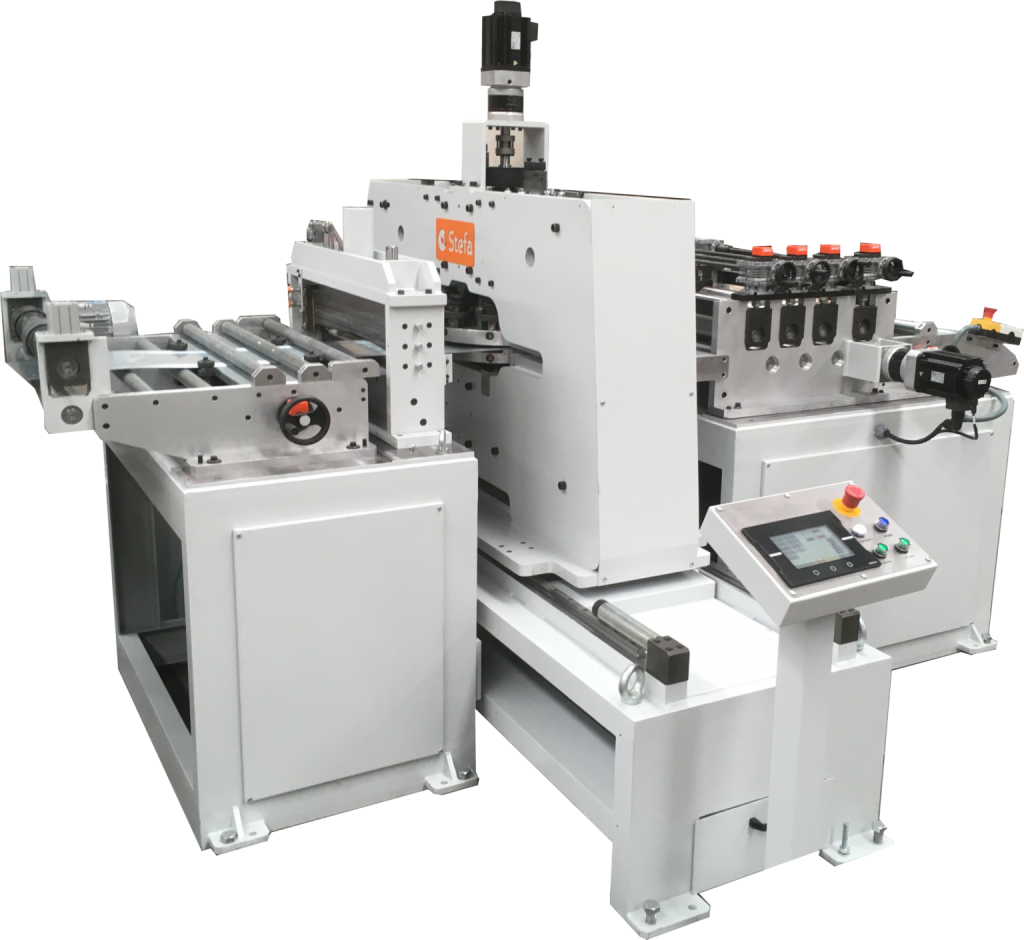

COIL PUNCHING

Selecting the Right Coil Punching and CTL Automation Solutions for Your Shop

Modern coil punching lines and CTL machines come in a range of configurations. Some shops benefit from servo-driven folders for fast, repeatable bends, while others need high-precision slitters or automated decoilers to keep up with demand. My role is to walk you through the real-world pros and cons of each option, factoring in your product mix, floor space, and ROI expectations. For instance, integrating a coil punching line upstream from your roll former can automate hole patterns, notches, and embossing—eliminating secondary operations and saving hours per shift.

Addressing Fabrication Needs: Precision in Slitting, Forming, and Folding

Roofing production increasingly calls for tight tolerances and versatile profiles. Advanced CTL systems let you dial in exact lengths, minimize scrap, and adapt to changing orders with minimal downtime. Servo-driven folders excel at complex bends, while combi-beam and double folder designs offer flexibility for both simple and intricate parts. Automated slitters can run multiple widths from a single coil, reducing inventory and improving material yield. By matching the right equipment to your fabrication needs, you achieve both precision and throughput.

Maximizing Throughput: Strategies for Enhancing Production Speed and Reducing Material Waste

Throughput isn’t just about machine speed—it’s about minimizing manual steps, material handling, and setup times. Automated coil punching and CTL lines can run lights-out, feeding downstream processes with consistent quality. Features like quick-change tooling, recipe storage, and integrated scrap management help reduce downtime and material waste. In many shops, these upgrades translate to 20–40% more output with the same or fewer operators, allowing you to take on larger jobs or diversify your offerings.

Real-World Results: Customer Success Stories in Efficiency Upgrades

I’ve worked with roofing shops that were struggling to keep up with custom panel orders, only to see dramatic improvements after adding automated coil punching. One customer cut panel production times in half, reduced overtime, and delivered more consistent products—all thanks to the right CTL and coil handling upgrades. Another fabricator was able to reallocate skilled labor from repetitive cutting tasks to higher-value assembly work, boosting morale and profitability. These aren’t just anecdotes—they’re proof that the right automation pays off.

Planning Your Upgrade: Steps for a Smooth Transition to Advanced Automation

Upgrading your line doesn’t have to mean shutting down for weeks. My process involves a thorough site assessment, equipment selection tailored to your needs, and a phased installation plan that keeps disruption to a minimum. We’ll coordinate training for your team, set up test runs, and provide hands-on support during ramp-up. By partnering with Mac-Tech, you gain access to a network of service professionals and a direct line to me for troubleshooting and advice.

Ongoing Support: Ensuring Long-Term Performance and ROI in Roofing Fabrication

The real value of automation comes from sustained uptime and continuous improvement. That’s why we offer preventive maintenance programs, remote diagnostics, and upgrade paths to keep your equipment running at its best. I stay in touch with customers long after installation, helping them adapt to new products, expand capacity, or fine-tune processes as market demands shift. Your success is my success, and I’m always just a call or email away.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent downtime, struggling to meet new product specs, or seeing labor costs rise due to manual processes, it’s time to consider an upgrade. The sooner you address bottlenecks, the faster you’ll see ROI.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer faster cycle times, tighter repeatability, and easier programming. They’re ideal for high-mix, low-volume work or shops looking to reduce setup time and operator intervention.

What’s the difference between a combi-beam and double folder?

A combi-beam folder gives you tooling flexibility for different profiles without tool changes, while a double folder can bend both up and down in a single cycle—boosting productivity for complex parts.

What are signs a roll forming line is no longer cost-effective?

Excessive scrap, frequent breakdowns, and long changeover times are red flags. If your line can’t keep up with order volume or new product requirements, it’s time to look at automation.

How do slitters and decoilers integrate with CTL and punching lines?

Modern systems can be fully integrated, allowing for continuous operation from coil to finished part. This reduces handling, improves accuracy, and shortens lead times.

Can I automate existing equipment or do I need a full line replacement?

In many cases, we can retrofit automation modules—like automated feeders or punching heads—to your existing line. A full replacement is only necessary if your current setup can’t meet future needs.

Ready to see how coil punching and CTL automation can boost your roofing production? I’m here to guide you every step of the way. Reach out for a personalized walkthrough, on-site demo, or a no-obligation quote. Let’s future-proof your shop together.

Get Weekly Mac-Tech News & Updates