From the steel mills of southern Chicago to fabrication shops across the Midwest, I’ve dedicated my career to helping manufacturers unlock new levels of efficiency. At Mac-Tech, I work side-by-side with roofing and fabrication businesses to evaluate, modernize, and future-proof their production lines. My customer-first approach means I’m not just selling equipment—I’m committed to delivering real, measurable improvements that move your business forward. Whether you’re expanding capacity or solving bottlenecks, I’m here to help you navigate the best solutions for your operation.

Leveraging Decades of Coil-Fed Production Expertise to Maximize Efficiency

Continuous coil-fed processing has transformed manufacturing by enabling uninterrupted production, reduced material waste, and faster throughput. Drawing on decades of hands-on experience, I guide customers through the process of integrating coil-to-laser systems that are tailored for their specific needs. From folders and shears to slitters, decoilers, and advanced panel benders, every machine in your line plays a vital role in production efficiency.

Many shops are still operating with manual or semi-automated setups that rely heavily on skilled labor. By shifting to continuous coil-to-laser integration, you gain the benefits of automation: consistent feeding, precise cutting, and minimal downtime. This approach is especially valuable for high-volume roofing, siding, and custom fabrication projects where material flow and accuracy are critical.

Evaluating Current Fabrication Processes for Waste Reduction and Productivity Gains

The first step in any upgrade is a thorough evaluation of your current workflow. I work with plant managers and operators to identify pain points—whether it’s manual handling, excessive scrap, or frequent changeovers. We analyze metrics like yield rates, cycle times, and labor utilization to build a clear case for where improvements will have the greatest impact.

For example, a roofing manufacturer recently approached Mac-Tech struggling with coil changeover delays and inconsistent part quality. After a detailed process audit, we recommended a coil-to-laser system with automatic decoiling and real-time nesting software. The result: reduced scrap rates, fewer operator interventions, and a significant increase in daily output.

Selecting Advanced Coil-to-Laser Solutions for Precise Slitting, Forming, and Folding

Choosing the right coil-to-laser equipment is about more than just speed—it’s about matching machine capabilities to your production goals. At Mac-Tech, we help customers compare technologies like servo-driven folders versus hydraulic systems, or the advantages of a combi-beam panel bender versus a traditional double folder.

Servo-driven folders, for instance, deliver superior accuracy and repeatability for tight-tolerance work, while hydraulic models may be better suited for heavy-gauge applications. Advanced slitters and forming machines with integrated controls enable seamless transitions between jobs, minimizing setup time and maximizing uptime.

We also look at downstream requirements, such as roll formers for downspouts or panel benders for architectural panels. By aligning each piece of equipment, you create a truly integrated line that supports continuous, just-in-time production.

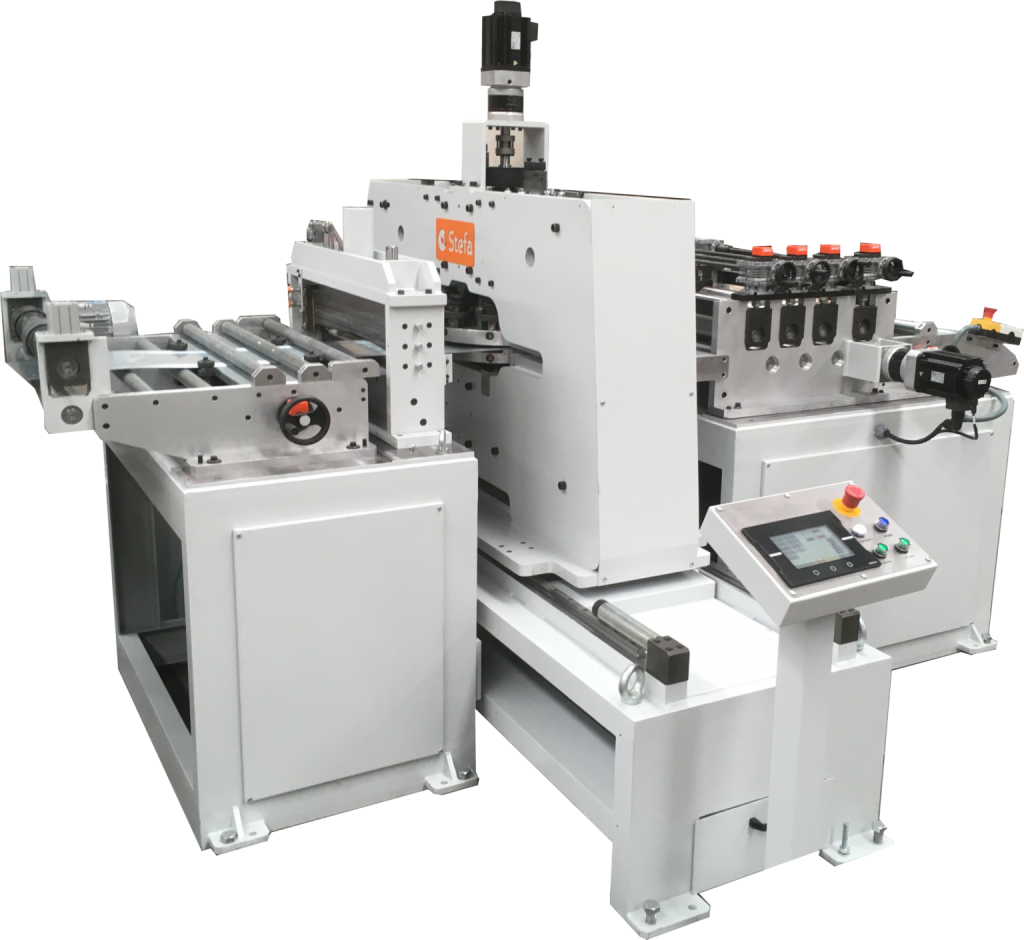

COIL PUNCHING MACHINE

3ADM 1200 Beam

Upgrading Equipment to Meet High-Speed and High-Volume Manufacturing Demands

As demand for custom and high-volume fabrication grows, legacy equipment often becomes a bottleneck. Upgrading to high-speed coil-to-laser systems not only boosts throughput but also reduces the need for rework and secondary operations.

I recently worked with a metal roofing company that was outgrowing their manual slitting and folding equipment. By upgrading to an automated coil-fed line with laser cutting and forming, they doubled their output while cutting labor costs by nearly 40 percent. The added precision allowed them to expand into new markets with more complex profiles and finishes.

When evaluating upgrades, I encourage customers to consider scalability, ease of integration, and future maintenance requirements. Investing in modular, open-architecture equipment ensures you can adapt as your business evolves.

Ensuring Seamless Integration and Ongoing Support for Sustained Operational Excellence

The transition to a continuous coil-to-laser line is more than a one-time purchase—it’s a partnership. At Mac-Tech, our team provides hands-on support from initial layout planning to installation, training, and ongoing service.

We focus on seamless integration with your existing systems, whether you’re adding a new decoiler, upgrading a folder, or implementing a complete coil-to-laser cell. Our service team is always available for troubleshooting, preventive maintenance, and software updates to keep your line running at peak performance.

Operational excellence doesn’t stop at commissioning. We offer ongoing process reviews and operator training to ensure you’re getting the most from your investment—today and for years to come.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent downtime, excessive scrap, or struggling to keep up with demand, it’s time to consider an upgrade. I recommend a thorough ROI analysis to determine if new technology will pay for itself through labor savings and increased output.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer faster setup, higher precision, and quieter operation. They’re ideal for applications requiring tight tolerances and frequent part changes. Hydraulic systems are robust and better suited for thicker materials or heavy-duty forming.

What’s the difference between a combi-beam and a double folder?

A combi-beam panel bender combines both up-and-down folding capabilities in a single machine, which maximizes flexibility. Double folders have two separate beams for complex bends but may require more space and setup time.

What are signs a roll forming line is no longer cost-effective?

Rising maintenance costs, increased downtime, inconsistent product quality, and inability to meet order volume are all red flags. If your competitors are delivering faster or at a lower cost, it’s time to evaluate an upgrade.

Can continuous coil-to-laser integration reduce labor needs?

Absolutely. Automation minimizes manual handling, reduces operator fatigue, and allows your team to focus on quality control and value-added tasks.

How do I know if my shop is ready for full automation?

If your order volume is growing, you’re facing labor shortages, or quality requirements are tightening, automation is worth considering. I can walk you through a readiness assessment and help you plan a phased approach if needed.

Looking to streamline your production, reduce waste, and boost throughput? I’m here to help you find the right coil-to-laser solution for your fabrication needs. Whether you want a plant walkthrough, a live demo, or a quote for an upgrade, reach out today—I’ll make sure you have the information and support you need to make the best decision for your business.

Get Weekly Mac-Tech News & Updates