Maximizing Precision in Metal Roofing with the Ermaksan Fibermak Raptor Series

As the National Sales Executive at Mac-Tech, I have dedicated my career to providing innovative machinery solutions that empower the metal roofing industry. With years of experience under my belt, I understand the critical role that precision and efficiency play in manufacturing high-quality metal roofing products. The Ermaksan Fibermak Raptor Series stands out as a game-changer in this regard, revolutionizing the cutting process for metal roofing and downspout manufacturing. This article delves into how this advanced technology ensures high-quality cuts, enhancing both efficiency and precision in production.

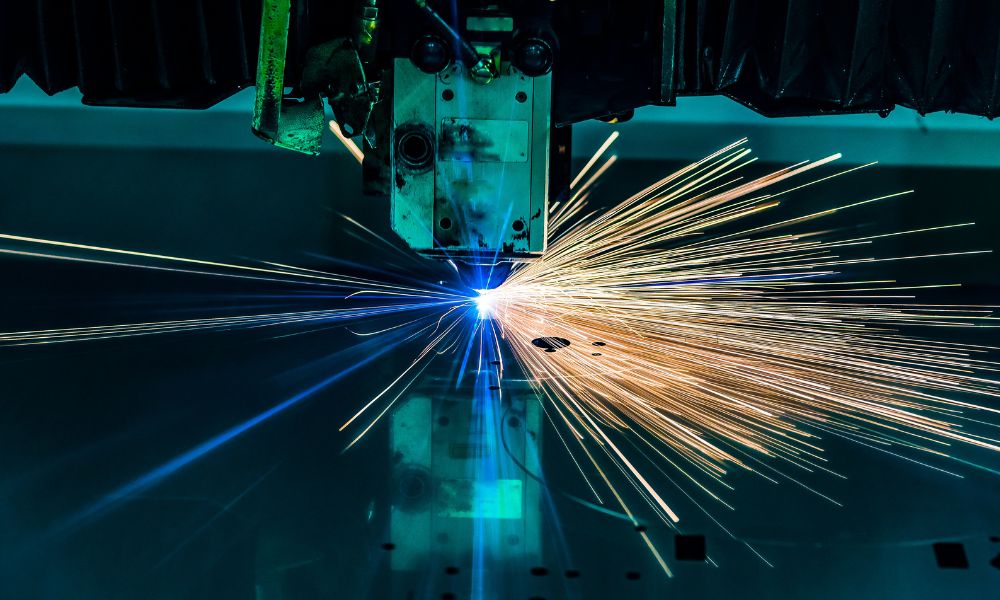

The Fibermak Raptor Series utilizes cutting-edge fiber laser technology, which offers unparalleled speed and accuracy. This machine is designed to handle a variety of materials, including stainless steel, aluminum, and mild steel, making it a versatile choice for roofing professionals. One of the standout features of the Raptor Series is its ability to deliver consistent, high-quality cuts with minimal kerf, which is crucial for maintaining the integrity of roofing components. The advanced motion control system further enhances precision, allowing for intricate designs and tight tolerances that are often required in modern roofing applications.

Moreover, the Ermaksan Fibermak Raptor Series is equipped with intelligent software that optimizes cutting paths and minimizes waste. This means that not only do you achieve superior cuts, but you also maximize material usage, ultimately leading to cost savings. The integration of automation and real-time monitoring allows manufacturers to streamline their operations, reducing downtime and increasing overall productivity. In an industry where every second counts, this level of efficiency can significantly impact your bottom line.

Tailored Solutions for Roofing Professionals: Mac-Tech’s Commitment to Excellence

At Mac-Tech, we recognize that every client has unique needs and challenges. Our commitment to excellence goes beyond simply providing machinery; we strive to deliver tailored solutions that leverage the capabilities of the Ermaksan Fibermak Raptor Series. Understanding our clients’ specific requirements is paramount, and we take the time to engage in meaningful conversations to ensure we provide the right equipment for their operations.

Our team is dedicated to offering comprehensive support, from the initial consultation to ongoing training and maintenance. We believe that investing in machinery is just the beginning; ensuring that our clients are fully equipped to utilize their equipment to its fullest potential is where we truly shine. We provide hands-on training sessions that empower operators to maximize the capabilities of the Fibermak Raptor Series, ensuring they can produce high-quality cuts consistently and efficiently.

Additionally, we offer ongoing support to address any challenges that may arise during the manufacturing process. Our commitment to customer success means that we are always just a phone call away, ready to assist with troubleshooting or optimizing machine performance. By fostering strong relationships with our clients, we ensure that they not only have access to top-tier machinery but also the expertise needed to thrive in a competitive market.

I Evaluate Press Brakes vs. Metal Folding Machines to Boost Roofing Efficiency

I Drive the Next Wave of Metal Roofing: Advancing Downspout Roll Forming, Bending, and Laser Cutting

FAQ

What maintenance is required for the Ermaksan Fibermak Raptor Series?

Regular maintenance includes cleaning the optics, checking the cooling system, and ensuring the mechanical components are lubricated. We provide detailed maintenance schedules to help you keep your machine in top condition.

How does the Fibermak Raptor Series improve efficiency?

The Raptor Series features advanced automation and intelligent software that optimizes cutting paths, reduces waste, and minimizes downtime, significantly enhancing overall efficiency in production.

Can the Raptor Series handle different materials?

Yes, the Fibermak Raptor Series is designed to cut a variety of materials, including stainless steel, aluminum, and mild steel, making it a versatile option for roofing professionals.

What kind of training does Mac-Tech offer?

We provide comprehensive training sessions tailored to your team’s needs, ensuring they are fully equipped to operate the Fibermak Raptor Series effectively and safely.

Is customization available for the machines?

Absolutely! We work closely with our clients to customize solutions that fit their specific manufacturing processes and requirements.

How can I get support after purchasing the machine?

Mac-Tech offers ongoing support through our dedicated customer service team, who are available to assist with any issues or questions you may have post-purchase.

What is the typical lead time for delivery?

Lead times can vary based on customization and demand, but we strive to provide timely delivery and keep our clients informed throughout the process.

I encourage you to consider the transformative solutions offered by the Ermaksan Fibermak Raptor Series. These machines not only enhance the quality of your cuts but also streamline your production processes, ultimately leading to greater success in your business. If you have any questions or would like to explore how we can assist you further, please don’t hesitate to reach out.

Get Weekly Mac-Tech News & Updates