Decoilers have emerged as indispensable tools in the metal roofing industry, offering transformative benefits that streamline production and enhance efficiency. As the demand for metal roofing continues to rise, manufacturers are seeking innovative solutions to meet this growing need. Decoilers stand out as a pivotal component in this evolution, providing a seamless integration into the fabrication process and ensuring that metal roofing projects are completed with precision and speed. In this article, we will explore how decoilers are revolutionizing metal roofing production, boosting efficiency, and elevating the quality of roofing projects.

Revolutionizing Metal Roofing with Decoilers

Decoilers have fundamentally changed the landscape of metal roofing production by automating the unwinding of metal coils. This automation reduces manual labor and minimizes the risk of material damage, leading to a more streamlined production process. By integrating decoilers into their operations, manufacturers can handle larger coils with ease, ensuring a steady and consistent supply of material for roofing projects. This consistency is crucial for maintaining the high standards expected in the industry.

Furthermore, decoilers contribute to a safer working environment. By automating the handling of heavy metal coils, they significantly reduce the risk of workplace injuries associated with manual coil handling. This not only protects workers but also enhances productivity, as employees can focus on more skilled tasks rather than the physically demanding and potentially hazardous job of coil management. The result is a more efficient and safer production line that can meet the demands of modern roofing projects.

The versatility of decoilers also plays a crucial role in their revolutionary impact on metal roofing production. They can accommodate a wide range of coil sizes and materials, making them adaptable to various project requirements. This flexibility ensures that manufacturers can quickly adjust their production processes to meet changing market demands, providing a competitive edge in the fast-paced construction industry.

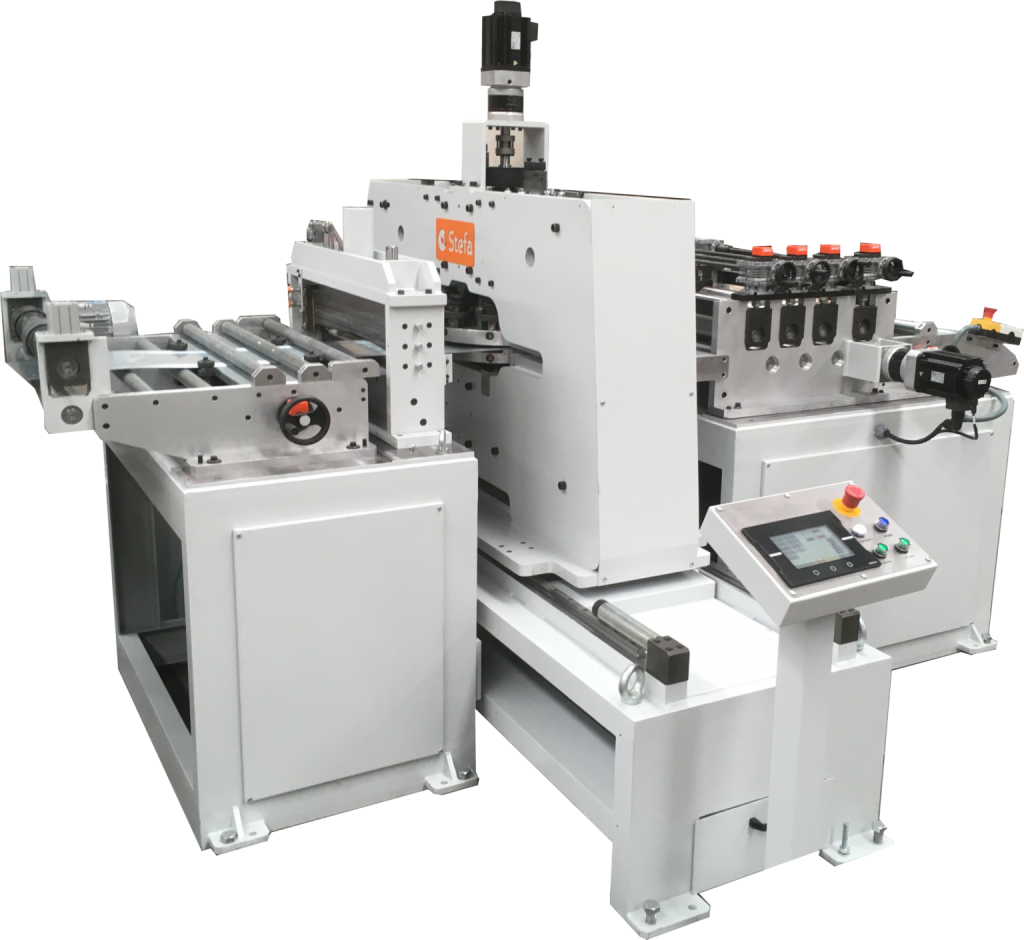

COIL PUNCHING MACHINE

PBD BEAM DRILLING MACHINE

Boost Efficiency in Roofing Production Today

Decoilers are essential for boosting efficiency in metal roofing production, allowing manufacturers to optimize their operations and reduce waste. By automating the unwinding process, decoilers ensure that material is fed smoothly and consistently into the production line, minimizing downtime and maximizing throughput. This efficiency translates into faster project completion times and the ability to take on more projects simultaneously.

In addition to improving production speed, decoilers help reduce material waste. By precisely controlling the unwinding of metal coils, they prevent overfeeding and material spillage, which can lead to costly waste and inefficiencies. This precision not only conserves resources but also contributes to a more sustainable production process, aligning with the growing emphasis on environmental responsibility in the construction industry.

Moreover, the integration of decoilers into roofing production lines can lead to significant cost savings. By reducing labor costs, minimizing material waste, and increasing production speed, manufacturers can achieve a higher return on investment. These savings can be reinvested into further improving production capabilities or passed on to customers, enhancing competitiveness in the market.

Decoilers: The Key to Seamless Metal Work

Decoilers are the key to achieving seamless metal work in roofing production, providing the precision and control needed to produce high-quality roofing materials. By ensuring a consistent feed of material, decoilers eliminate the risk of irregularities and defects that can compromise the integrity of the final product. This consistency is vital for maintaining the aesthetic and functional standards expected in modern roofing projects.

The precision offered by decoilers also enhances the quality of metal roofing products. By providing a steady and controlled feed of material, they enable manufacturers to produce roofing components with exact specifications and minimal variation. This precision ensures that roofing panels fit together perfectly, reducing the risk of leaks and other issues that can arise from poorly fitting components.

Additionally, decoilers contribute to a more efficient production workflow by integrating seamlessly with other equipment in the production line. This integration allows for a continuous and uninterrupted flow of material, reducing bottlenecks and ensuring that each stage of the production process operates at optimal efficiency. By facilitating a smooth and coordinated workflow, decoilers help manufacturers deliver high-quality roofing products on time and within budget.

Elevate Your Roofing with Advanced Decoilers

Advanced decoilers offer a range of features that can elevate your roofing production to new heights. With options such as automatic tension control, variable speed settings, and remote operation capabilities, these state-of-the-art machines provide unparalleled control and flexibility. These features enable manufacturers to fine-tune their production processes, ensuring that each project is completed with the highest level of precision and efficiency.

Investing in advanced decoilers can also enhance the scalability of your roofing production operations. As demand for metal roofing continues to grow, having the capability to quickly and efficiently scale up production is crucial. Advanced decoilers provide the capacity and adaptability needed to meet increasing demand without compromising on quality or efficiency.

Moreover, the integration of advanced decoilers into your production line can improve overall operational efficiency. By reducing setup times, minimizing maintenance requirements, and enhancing material handling capabilities, these machines streamline the entire production process. This efficiency not only boosts productivity but also enhances the overall competitiveness of your business in the roofing industry.

FAQ

What is a decoiler and how does it work?

Decoilers are machines used to unwind metal coils, feeding material into the production line with precision and control. They automate the handling of coils, reducing manual labor and minimizing material waste.

How do decoilers improve safety in metal roofing production?

By automating the unwinding of heavy metal coils, decoilers reduce the risk of workplace injuries associated with manual coil handling, creating a safer working environment.

Can decoilers handle different types of metal coils?

Yes, decoilers are versatile and can accommodate a wide range of coil sizes and materials, making them adaptable to various project requirements.

What are the cost benefits of using decoilers in roofing production?

Decoilers reduce labor costs, minimize material waste, and increase production speed, leading to significant cost savings and a higher return on investment.

How do advanced decoilers enhance production efficiency?

Advanced decoilers offer features like automatic tension control and variable speed settings, providing greater control and flexibility to optimize production processes.

Are decoilers suitable for small-scale roofing operations?

Yes, decoilers can be beneficial for both small and large-scale operations, as they improve efficiency and reduce waste, making them a valuable investment for any size of production.

What should I consider when choosing a decoiler for my business?

Consider factors such as coil size and material compatibility, automation features, and integration capabilities with existing equipment to ensure the decoiler meets your production needs.

Get Weekly Mac-Tech News & Updates