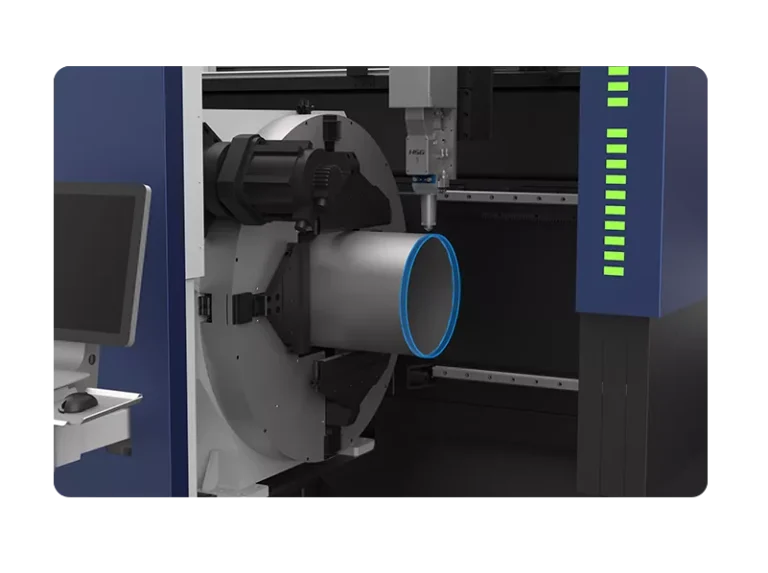

PCR41 Robotic Plasma Cutting System: Smart 4‑Face Structural Steel Processing That Drives ROI and Growth

Kyle Bialozynski leverages field experience to deliver smart 4‑face steel fabrication that boosts ROI, always putting customer satisfaction first. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413