I’m Kyle Bialozynski, a Sales Executive at Mac-Tech, and most weeks I’m walking shop floors across the Midwest seeing what really slows production down. A common pain point I run into is plasma cutting turning into the pacing item for the whole fab line, with parts waiting on cleanup, inconsistent edges, and long cycle times that make the brake and weld cells sit idle. In winter, it gets worse when air quality, consumables, and uptime start acting up and nobody has time for extra troubleshooting. When a shop asks me about ROI on a plasma to HSG fiber laser upgrade, I focus on what you actually cut and how that work moves through your building.

Replace Plasma Bottlenecks with Fiber Laser Cut Times You Can Schedule Around

Plasma is a workhorse, but it can be hard to schedule when cut speeds vary by thickness, edges need cleanup, and consumables drift over a shift. That uncertainty turns into piles of WIP and a constant shuffle of priority jobs.

An HSG fiber laser upgrade is usually the turning point when you need predictable cut times and repeatable part quality that feeds bending and welding without delays. Day to day, that means your cut cell stops being the bottleneck and starts behaving like a scheduled process with fewer surprises and fewer touchpoints.

Shorten Setup and Changeovers with Touchscreen Nesting, Auto Focus, and Consistent Pierce Quality

On many plasma tables, setup time hides in plain sight: dialing consumables, checking torch height, re-squaring sheets, and babysitting pierces to avoid tip-ups. Operators end up spending too much time getting ready to cut instead of cutting, especially with mixed jobs and frequent material changes.

With HSG fiber, touchscreen controls, modern nesting workflows, and auto focus reduce the manual adjustments that eat up a shift. Consistent pierce behavior also means less trial and error at the start of a job, so changeovers become something your team can repeat the same way every time with less operator stress and less scrap.

Improve Part Accuracy and Edge Condition to Reduce Grinding, Rework, and Weld Prep Time

Plasma often creates a downstream tax: dross cleanup, edge grinding, and extra weld prep to make parts fit the way they should. Even if the plasma table is fast enough, the hidden cost shows up when your welders are doing cleanup work instead of welding, or when holes and slots require secondary ops.

A fiber laser’s cleaner edge condition and tighter accuracy typically reduce the amount of grinding and rework needed before bending and welding. In day-to-day terms, parts come off the table closer to ready-to-run, and your fit-up improves so you spend less time fixing problems that started at the cut cell.

Boost Throughput with Faster Material Handling, Smaller Footprint, and Cleaner Workcell Flow

A lot of plasma cells are surrounded by pallets, scrap, and staging because the process needs room to breathe and parts need somewhere to cool and get cleaned. That sprawl makes it harder to keep material flowing cleanly from raw sheet to cut parts to the next operation, especially when forklifts are threading the needle.

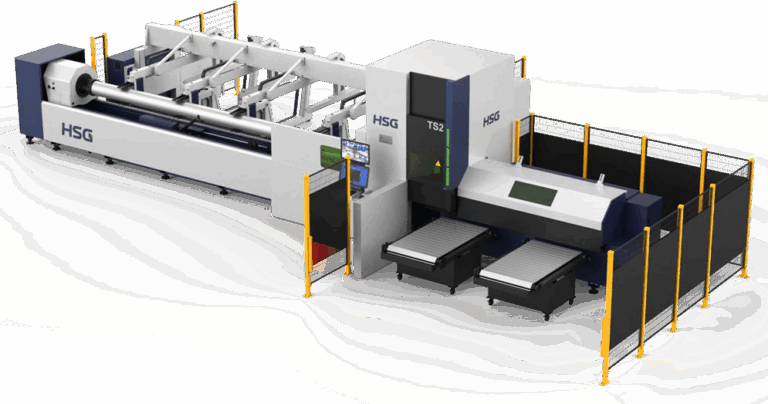

HSG fiber laser systems can be configured to tighten the workcell footprint and improve material flow, and automation can be added when your mix and volume justify it. At a high level, you are planning for solid floor, straightforward power, and clean, dry air, then building a flow where sheets come in, parts go out, and scrap handling is simple and repeatable.

HSG TS2 HIGH SPEED TUBE FIBER LASER CUTTING MACHINE

HSG 3015H 12KW

Lower Operating Cost with Reduced Consumables, Less Power Draw, and Higher Uptime in Daily Use

Plasma operating cost is not just consumables, it is the time spent swapping them, tuning cut quality, and dealing with variability when air and humidity change. You also feel it in power draw and in the labor hours tied up in cleanup and rework that never shows up as a line item on the cut department.

Fiber laser operating cost tends to drop because you are buying fewer wear items, using power more efficiently for the work being done, and holding cut quality more consistently through the day. Maintenance also becomes more habit-based: keep lenses and nozzles clean, keep your air dry, and follow a simple PM schedule to protect uptime when the weather turns.

Next Steps for a Shop Floor ROI Review and Right Sized HSG Fiber Laser Upgrade

The right upgrade starts with your actual cut list: material types, thickness range, hole and slot density, part sizes, and how often you change jobs. I like to walk the material flow from receiving to cutting to bending to welding so we can spot where time is really being lost and whether the biggest win is speed, quality, scheduling consistency, or all three.

From there, we right-size the HSG fiber laser around your work, your floor space, and your staffing plan, and we talk honestly about when automation helps versus when it adds complexity. If you want to see examples of equipment and options, you can also browse https://shop.mac-tech.com/ to get familiar with what a modern cut cell can look like.

FAQ

How do I know if upgrading from plasma to a fiber laser is worth it for my shop?

If you are spending real time on edge cleanup, rework, and unpredictable schedules, the ROI usually shows up quickly in labor savings and smoother throughput, not just inches per minute.

What thickness range makes sense for an HSG fiber laser compared to plasma?

It depends on your mix, but fiber tends to shine when you need cleaner edges, faster cycles on a wide range of common fab thicknesses, and more consistent hole and slot quality.

Do I need automation right away, or can I add it later?

Many shops start with manual load and unload and add automation once they have stable scheduling and know their true volume and staffing constraints.

What should I plan for in footprint, power, and air needs?

Plan for a cleaner, more organized workcell than most plasma layouts, plus adequate electrical service and dry, clean compressed air to protect cut quality and reliability.

How long does operator training usually take when moving from plasma to fiber?

Most operators pick up basic operation quickly, and the bigger win comes from standardizing setups and nesting so every shift runs the machine the same way.

What maintenance habits matter most, especially for winter reliability?

Keep air dry, follow the recommended PM schedule, and stay consistent with cleaning and inspection routines so cold weather does not turn into downtime.

Are financing or trade-in options available for a plasma-to-fiber upgrade?

Yes, we can review financing and trade-in scenarios as part of the ROI discussion so the upgrade matches your cash flow and production plan.

If you want a practical ROI review based on your real cut jobs and shop flow, reach me at kyle@mac-tech.com or 414-704-8413, or visit https://shop.mac-tech.com/.

Get Weekly Mac-Tech News & Updates