Structural fabricators in oil and gas, bridge, shipyard, and tower work are getting squeezed from both sides: fewer qualified operators on the floor and tighter delivery windows that cannot absorb a press brake outage or a week of rework. When bend capacity is mis-sized or uptime is fragile, the result is predictable: overtime, missed ship dates, and field-fit issues that cost more than the machine payment. I work as the single point of contact for turnkey, ROI-driven press brake cells, coordinating machine selection, automation integration, layout, commissioning, training, and long-term service continuity across the full line.

Uptime and Capacity Constraints in Structural Fabrication Press Brake Cells

The executive constraint is not just tons and bed length. It is whether the brake cell can reliably support shift-by-shift throughput for thick plate, long parts, and mixed beam and gusset work without creating queues upstream or downstream. In structural fabrication, a press brake bottleneck typically shows up as schedule risk, labor instability, and avoidable material handling exposure.

Typical constraints I see in the field

- 2–6 hours/week lost to unplanned stoppages tied to controls alarms, backgauge issues, or inconsistent tooling setups

- 30–90 minutes/changeover when programs, tooling, and material staging are not standardized

- 10–20% utilization loss from waiting on forklift moves, part flips, or downstream fit-up feedback loops

- 2–5% rework driven by angle variance across long parts, inconsistent crowning compensation, or mis-sequenced bends

Decision Criteria for Liberty vs Ermaksan Capacity, Tooling, and Integration ROI

Liberty and Ermaksan can both solve structural bending requirements, but the correct decision framework starts with the cost of downtime and the cost of overbuying. The goal is to right-size tonnage, length, and control capability to your real mix, then confirm serviceability and integration readiness so uptime and labor savings are bankable.

Capacity and tooling fit criteria

- Tonnage and length aligned to peak jobs, not one-off extremes, to avoid underutilized capital (target 65–85% planned utilization)

- Tooling strategy that reduces touchpoints: common toolsets covering 70–90% of part families, minimizing tear-down frequency

- Setup time targets: <20 minutes for repeat work, <45 minutes for new work with verified offline programming

Integration ROI criteria

- Controls and interfaces that support future automation without retrofit surprises (I/O, safety, and cell communication readiness)

- Service model suitability for 2–3 shift operations: parts availability, remote support, and local response expectations

- Payback modeled from measurable drivers: labor hours removed from handling and setup, scrap reduction, and recovered uptime

For teams comparing options, I typically benchmark Liberty vs Ermaksan against the same scorecard: uptime risk, service continuity, and the cost per part under your actual shift plan. When it is time to validate configurations and accessory packages, Mac-Tech’s product and application resources are available through https://shop.mac-tech.com/.

Liberty and Ermaksan Solution Paths for Press Brake Automation and Throughput

In structural environments, the highest-return improvements usually come from stabilizing flow before chasing maximum tonnage. Liberty or Ermaksan press brakes can be specified as standalone high-mix stations or as the center of an automated cell, but the configuration should match your material movement reality and your operator bench strength.

Throughput and labor stabilization options

- Standardized tooling and offline programming to reduce first-article time and avoid on-floor trial bends

- Material flow improvements: dedicated staging, part carts, and controlled flip zones to cut forklift interruptions by 20–40%

- Automation-ready layouts that keep guarding, scanner zones, and access lanes consistent with future add-ons

When a full structural line is in play, we often map bending alongside upstream cutting and prep so the brake is not isolated. Depending on scope, that can include pairing the press brake cell with HSG Fiber Lasers for plate processing, Akyapak for plate rolling, Ercolina for tube and profile bending, and Prodevco for beam coping and drilling, then aligning WIP buffers to protect press brake uptime.

Implementation Risks and Mitigations for Controls, Safety, and Material Flow Integration

The business risk is not the purchase order. It is disruption during install, safety validation delays, and integration gaps that turn a new brake into a new bottleneck. My job is to reduce those risks with a defined plan for controls compatibility, safeguarding, and material flow so you can keep shipping while the cell is brought online.

Common risks and how we mitigate

- Controls and programming mismatch

- Pre-commission checks for job library structure, revision control, and program proving expectations

- Safety and guarding delays

- Early definition of scanner zones, fence lines, and access points to avoid rework during install

- Material flow breakdowns after go-live

- A documented WIP buffer plan, lift-assist requirements, and forklift traffic rules to protect cycle time and reduce near-misses

What I coordinate as the single point of contact

- Layout planning with your aisle constraints, crane coverage, and staging requirements

- Installation scheduling to minimize production interruption (weekend cutovers when practical)

- Training and ramp plan by shift, including setup standards and troubleshooting ownership

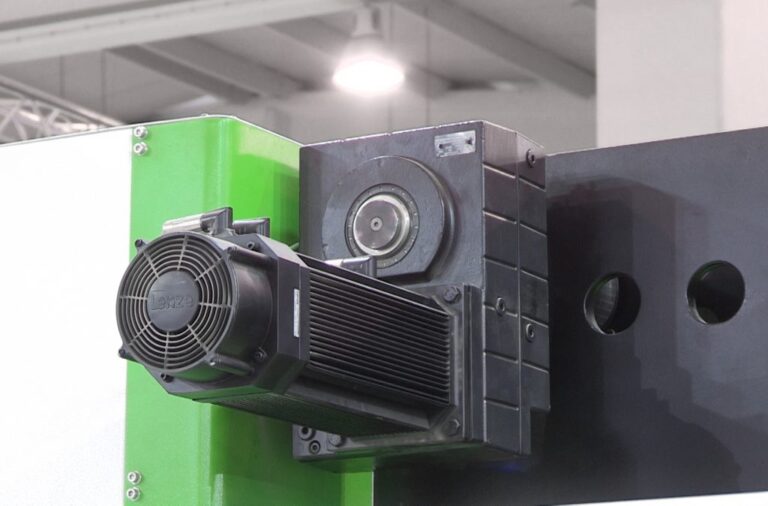

ERMAKSAN POWER-BEND FALCON BENDING MACHING

Measurable Outcomes Framework OEE, Cost per Part, Payback, and Uptime Gains

Executives need a scoreboard that survives the first 90 days, not a theoretical spreadsheet. I use an outcomes framework tied to OEE, cost per part, and uptime, with baselines collected before equipment arrives and a ramp curve that reflects staffing and mix.

Scoreboard metrics that typically move

- Uptime: +3–8% within the first quarter when setup standards, tooling discipline, and response plans are implemented

- Changeover time: 20–50% reduction by consolidating toolsets and standardizing programs and inspection checks

- Rework: 1–3 point reduction from consistent crowning compensation, repeatable gauging, and controlled first-article approval

- Labor impact: 0.5–2.0 FTE equivalent capacity returned through reduced handling, fewer retries, and faster setups

ROI and payback discipline

- Payback modeled from verified drivers: recovered hours per shift, scrap and rework reduction, and reduced expediting

- Monthly review cadence during ramp: OEE, queue time, and top three downtime causes with corrective actions

- Documentation for lifecycle support so gains do not fade when staffing changes

If you want a quick way to align equipment scope with ROI targets, Mac-Tech’s configuration and accessory resources can be referenced at https://shop.mac-tech.com/.

Next Steps for Structural Fabricators with Dave Graf as Single Point of Contact for Automation Integration

The fastest path to a sound Liberty vs Ermaksan decision is a short discovery cycle: current mix, part families, shift plan, and where downtime or handling is costing you. From there, I build a capacity and uptime model, propose a right-sized press brake configuration, and map integration steps so you can implement without overbuying.

What to prepare for an executive review

- Last 60–90 days of bend demand by material, thickness, and part length

- Current changeover time, first-article approval time, and top downtime codes

- Material flow sketch: forklift touches per part, queue time, and where parts wait

If the project expands beyond bending, I will coordinate the broader line alignment so cutting, coping, rolling, and bending support a single throughput plan. When it is helpful for ROI validation and project tracking discipline, some teams also use operational workflow tools referenced at https://vayjo.com/ to keep implementation actions visible across production, maintenance, and safety.

FAQ

What are typical lead times for a press brake and integration scope?

Lead times vary by configuration and options, but I plan around realistic build, freight, and commissioning windows and provide a milestone schedule tied to your production calendar.

How do you reduce the risk of downtime during the changeover to a new brake cell?

We use a phased ramp plan with parallel capability where possible, predefined job prove-out steps, and clear ownership for alarms, tooling, and first-article approvals.

What training is required for operators and maintenance?

Training is structured by role and shift, covering safe operation, repeatable setups, and first-response troubleshooting, with follow-up support to stabilize performance after go-live.

How is ROI measured after installation?

We baseline OEE, changeover time, rework, and queue time before install, then track the same metrics weekly during ramp so payback is tied to verified hours and scrap reduction.

Can Liberty or Ermaksan be specified for future automation even if we start manual?

Yes, if we select the right controls, safety architecture, and layout footprint up front, you can add automation later without reworking guarding and material flow.

Who coordinates service continuity across multiple machines in the line?

I stay accountable as the one-call owner, aligning Mac-Tech resources, OEM support, and your internal maintenance plan so uptime protection is not fragmented.

Contact Dave Graf for planning, demonstrations, or full project coordination: dave@mac-tech.com | 602-510-5552 | https://shop.mac-tech.com/

Get Weekly Mac-Tech News & Updates