As someone who grew up in southern Chicago surrounded by hardworking fabricators and tradespeople, my career has always been about connecting with customers on their shop floor. Having spent decades in the field and now serving as National Product Manager and Regional Sales Executive at Mac-Tech, I’m driven by a simple mission: help roofing and fabrication businesses find the best solutions to modernize their production lines. Every day, I work with companies to evaluate and upgrade folders, shears, slitters, decoilers, downspout roll formers, panel benders, and more. My approach is hands-on, practical, and always tailored to the unique needs of your operation.

Leveraging Real-World Experience: Optimizing Coil-Fed Production for Maximum Efficiency

Coil-fed sheet metal production is the backbone of many fabrication shops, but maximizing its efficiency takes more than just installing new machines. The right process starts with a deep dive into your current workflow. Are you running a high-volume roofing panel line or producing custom architectural components? I’ve seen firsthand how panel benders, when integrated thoughtfully, can transform coil processing by reducing manual handling and automating complex bends. For one Midwest client, introducing a modern panel bender cut changeover time in half and allowed for near-continuous operation, maximizing their coil investment and boosting output without expanding their footprint.

Identifying Bottlenecks: Evaluating Machine Performance in Slitting, Forming, and Folding Operations

A common challenge I encounter is hidden bottlenecks in slitting, forming, or folding operations. Even the best roll former or slitter can only perform as fast as the slowest step in the process. That’s why I always start with a thorough performance evaluation across the entire line. Is your folder keeping up with your slitter? Are your operators manually repositioning panels between stages? Advanced panel benders now feature automated positioning and integrated handling, eliminating delays and reducing the risk of error. By benchmarking cycle times and scrap rates, I help clients identify where upgrades will deliver the greatest ROI.

Upgrading for Success: Selecting Panel Benders that Reduce Waste and Boost Throughput

Choosing the right panel bender is about more than just specs—it’s about matching technology to your real production needs. I guide customers through side-by-side comparisons of servo-driven versus hydraulic systems, combi-beam versus double folder designs, and software integration options. Modern servo-driven panel benders offer faster, more precise operation with less maintenance, while advanced control systems enable tighter tolerances and recipe-driven production. The result is a measurable drop in material waste and a significant boost in throughput. For example, one customer in the commercial roofing sector saw a 30% reduction in offcuts after upgrading to a new panel bender with automatic blank sizing.

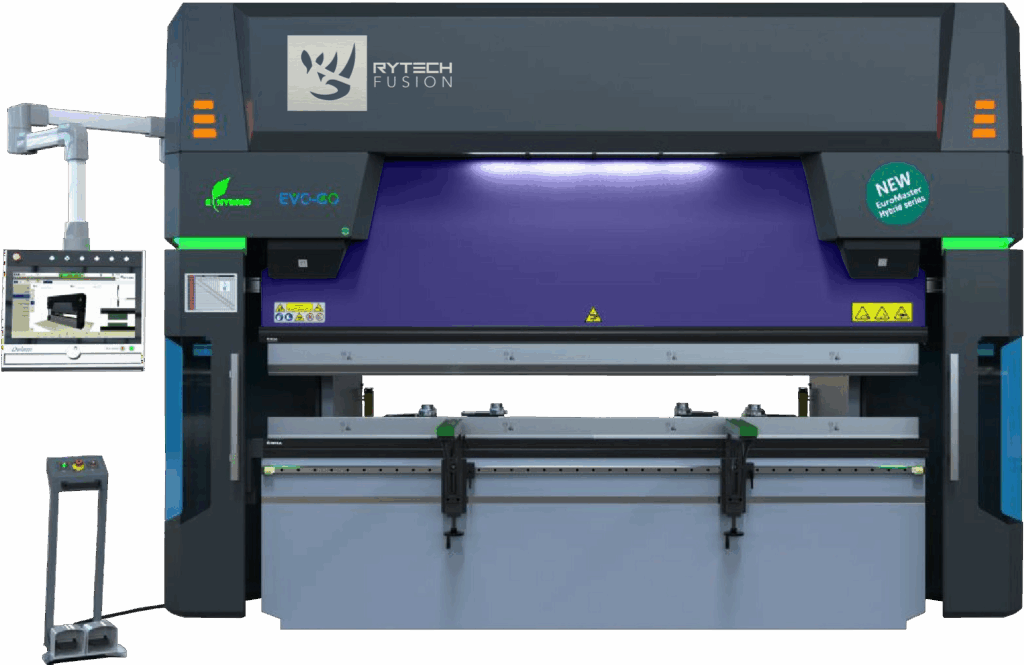

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

GREEN FX SERVO

Tailoring Solutions: Meeting Diverse Fabrication Needs with Advanced Panel Bending Technology

No two fabrication shops are alike, so our approach at Mac-Tech is always to tailor solutions. Some clients need compact machines for custom work; others require heavy-duty panel benders to handle high-strength steel or aluminum. I work closely with each customer to consider not just the immediate production challenge but also future growth and integration with existing equipment. Whether you’re running architectural panels, downspouts, or custom trim, the right panel bender can adapt to multiple profiles and batch sizes with minimal setup. Our team provides hands-on demos and training to ensure a smooth transition and long-term productivity gains.

Achieving Sustainable Gains: Pat O’Neill’s Proven Strategies for Enhanced Productivity in Roll Forming and Metal Folding

Sustainable productivity isn’t just about the newest machine—it’s about a strategic upgrade path. My proven strategies start with a comprehensive audit of your current equipment, followed by targeted recommendations for phased upgrades. We focus on automation, operator safety, and data-driven performance monitoring. By integrating advanced panel benders into coil-fed lines, customers consistently report lower labor costs, improved product quality, and the ability to take on more diverse, higher-margin jobs. My role is to be your trusted partner from evaluation through installation and ongoing support.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent downtime, excessive scrap, or struggling to meet new project specs, it’s time to consider an upgrade. I recommend a performance assessment to pinpoint where your process is falling behind and what level of investment will yield the best results.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders provide faster, quieter, and more precise operation with lower energy use and less maintenance. They’re especially beneficial for shops needing tight tolerances or frequent job changes.

What’s the difference between a combi-beam and double folder?

A combi-beam panel bender offers flexibility for different bend profiles in a single machine, while a double folder uses two bending beams for faster production of complex parts. The right choice depends on your product mix and desired throughput.

What are signs a roll forming line is no longer cost-effective?

Look for rising maintenance costs, growing scrap rates, or inability to meet delivery schedules. If your line can’t keep up with demand or new material requirements, it’s time to evaluate an upgrade.

Can panel benders handle both standard and custom profiles?

Absolutely. Today’s advanced panel benders are highly programmable and can switch between standard and custom profiles with minimal setup, making them ideal for diverse fabrication needs.

How can automation help reduce labor costs in coil-fed production?

Automated panel benders and integrated handling systems minimize manual intervention, reduce errors, and allow operators to focus on value-added tasks, leading to significant labor savings over time.

If you’re considering an upgrade or want to see firsthand how panel benders can transform your coil-fed production, let’s connect. I’m always happy to provide a walkthrough, arrange a live demo, or deliver a tailored quote. Reach out to me at pat@mac-tech.com or 414-232-7929, and let’s take your fabrication business to the next level.

Get Weekly Mac-Tech News & Updates