-

Ercolina Solutions Enhance Complex Curves in Bridge Construction

The article by Dave Graf, Regional Sales Executive at Mac-Tech, highlights how Ercolina Solutions are revolutionizing the construction of complex curves in bridge projects. These solutions offer end-to-end automation for structural steel fabrication, which significantly benefits the oil & gas, shipbuilding, bridge, and tower construction industries. By streamlining processes and enhancing precision, Ercolina Solutions help…

-

Expand Steel Shop Capacity with Prodevco Robotic Beam Coping Systems

Prodevco Automation aids Illinois steel shops in boosting capacity by using robotic beam lines for precise layouts, cutting manual labor and costs in bridge and high-rise projects. Contact Mac-Tech: 888-MAC-9555

-

Ermaksan Tandem Press Brakes: Section 179 Write-Offs for Shipyards & Wind Farms

Leverage Section 179 to accelerate ROI on large-format press brakes; align capex with schedule peaks for shipyards and wind farms to scale capacity. Joe Ryan President, Mac-Tech joe@mac-tech.com | 414-477-8772 | 888-MAC-9555

-

Precision Slitting in Coil Systems Reduces Waste and Rework

The article by Patrick (Pat) O’Neill discusses how precision slitting in coil systems can significantly reduce waste and rework in manufacturing processes. Pat, National Product Manager and Regional Sales Executive at Mac-Tech, emphasizes the importance of selecting the right machines, incorporating automation, and engaging in practical planning to enhance production efficiency, improve forming accuracy, and…

-

Robotic Integration with Rytech Press Brakes Speeds Setup and Reduces Fatigue

The article by John Perry highlights the benefits of integrating robotics with Rytech press brakes, focusing on how this combination enhances setup speed and reduces operator fatigue. By utilizing automation, manufacturers can streamline operations, resulting in increased efficiency and productivity. John Perry, a Regional Sales Executive at Mac-Tech, assists manufacturers in making informed, ROI-driven decisions…

-

Prodevco Systems Elevate Iowa Projects: Accuracy, Uptime, Profitability Boost

Prodevco Systems enhance Iowa’s structural projects by solving production issues, boosting accuracy, uptime, and profitability. Local contractors praise results. Contact Mac-Tech: 888-MAC-9555

-

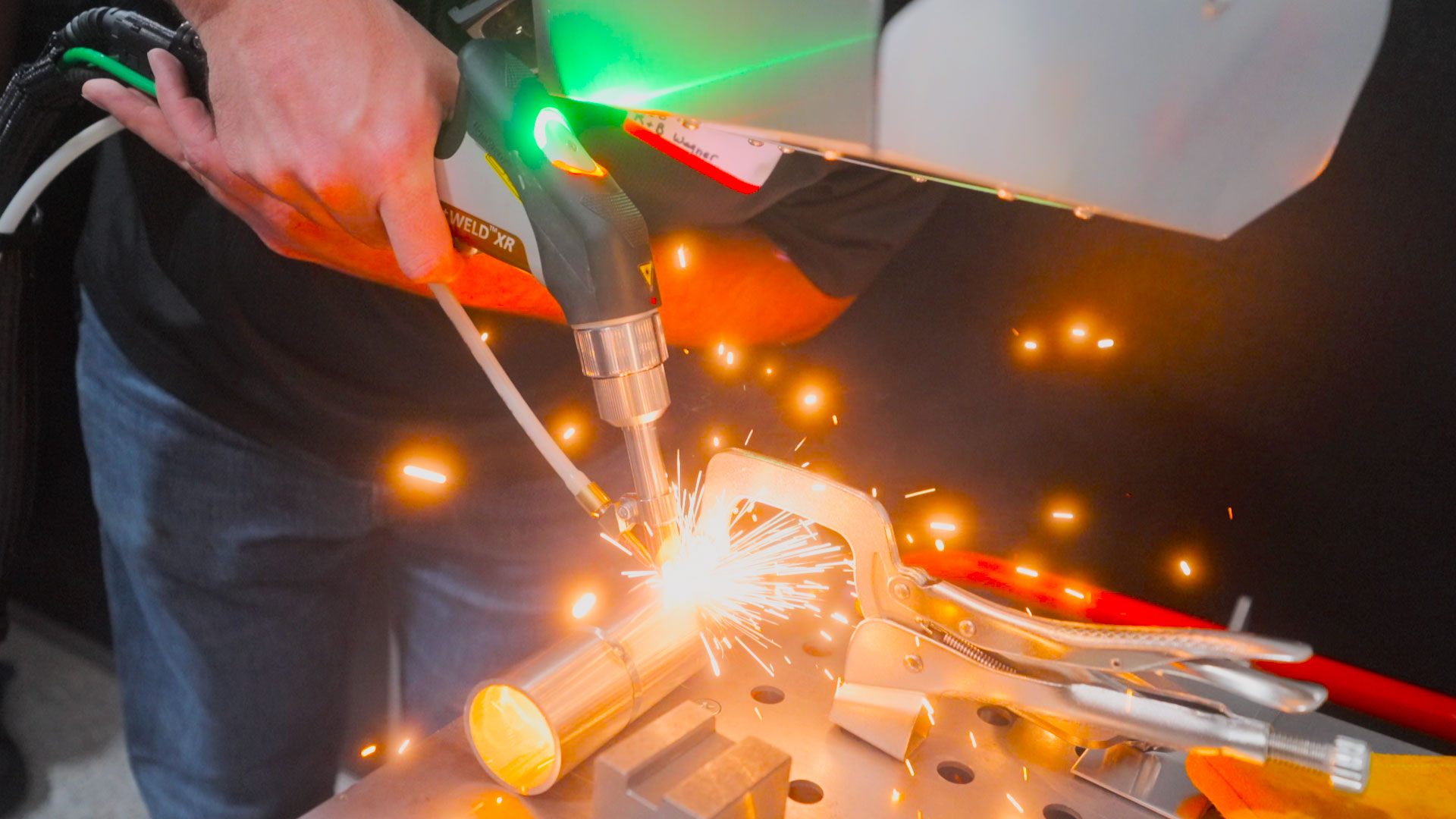

Optimizing CNC Press Brakes with HSG Laser Integration

Adam Quoss, VP of Sales at Mac-Tech, provides a hands-on perspective on optimizing CNC press brakes with HSG laser integration. He offers practical guidance for decision-makers seeking to modernize fabrication operations, emphasizing enhanced precision, efficiency, and cost-effectiveness as key benefits, ultimately driving competitive advantage in the manufacturing industry.