Born and raised on the south side of Chicago, I learned early on that success in manufacturing isn’t just about the machines—it’s about the people and the relationships you build along the way. After decades in the field, from the shop floor to national product management, I’ve seen firsthand how the right technology can transform a business. At Mac-Tech, my job is to help roofing and sheet metal shops navigate the maze of new equipment, avoid costly missteps, and unlock efficiency that puts them ahead of the competition. Whether you’re replacing a legacy shear, evaluating a new double folder, or planning a full-line upgrade, my focus is always on helping you make the smartest investment for your unique operation.

Leveraging Decades of Experience to Optimize Metal Roofing Production

Metal roofing fabrication has evolved rapidly over the past decade, with new demands for precision, speed, and labor efficiency. My role at Mac-Tech is to cut through the noise and offer solutions that aren’t just high-tech, but high-impact. I work with owners, plant managers, and operators to analyze current workflows—whether you’re running coil-fed lines, manual folders, or automated panel lines—and recommend upgrades that drive measurable results. From the first phone call to post-install support, I’m there every step of the way to ensure your investment pays off.

Evaluating Current Coil-Fed Systems for Efficiency and Waste Reduction

One of the biggest challenges I see in traditional coil-fed systems is balancing throughput with material waste. Older folders and roll formers often require excessive manual handling, leading to increased scrap, bottlenecks, and inconsistent panel quality. By integrating advanced double folder technology—like the Stefa VHX series—we can dramatically reduce handling time and optimize nesting, so you get more sellable product from every coil. These systems are designed with positive and negative bending capabilities, allowing for complex profiles in a single pass and minimizing operator intervention.

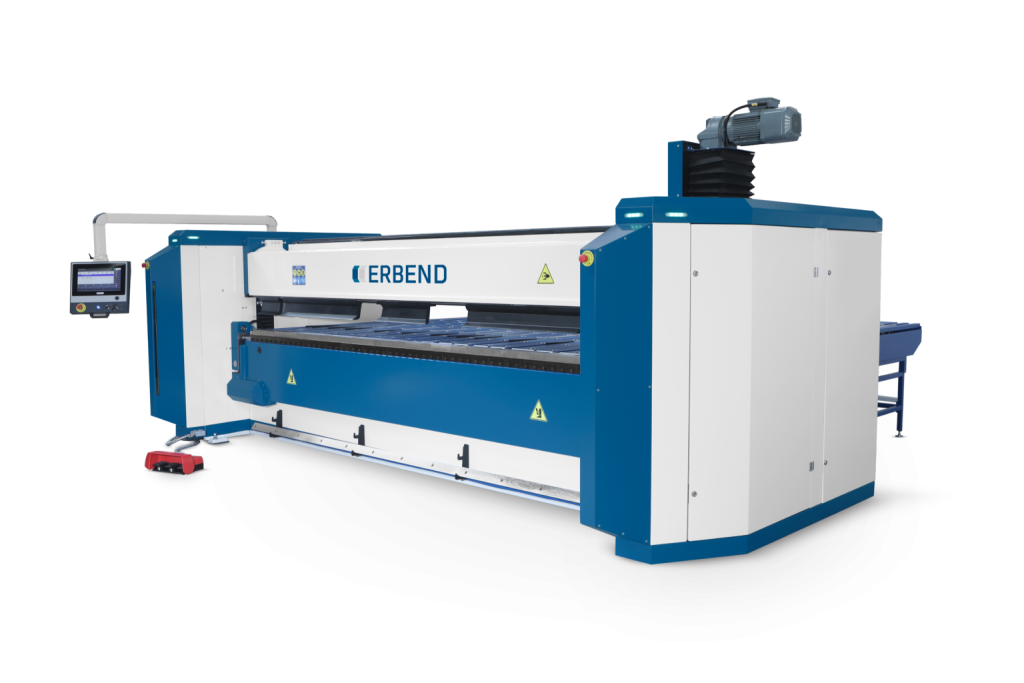

DR. HOCHSTRATE 3200*6

ERBEND MFA

Addressing Fabrication Challenges: Slitting, Forming, and Folding Solutions

Roofing shops face unique challenges—slitting accuracy, forming consistency, and the ability to fold thicker gauges without sacrificing quality. Double folders with hybrid servo-hydraulic technology offer precise closed-loop control of acceleration and velocity, ensuring tight tolerances even on long runs. The reinforced, removable bending beam tools allow for both large and small radius bends, accommodating a range of roofing profiles from standing seam to custom trims. Automated grippers and dual backstops enable 90° bends up to 45 mm high, while advanced safety systems protect operators without slowing down production.

Upgrading to Double Folders: Key Considerations for Enhanced Performance

When considering a double folder upgrade, it’s important to evaluate more than just the headline specs. I walk customers through factors like:

- Working length vs. available floor space (options from 10.5ft to 27.5ft)

- Maximum thickness requirements (up to 2mm / 14ga aluminum or steel)

- Automation level (fully automatic vs. semi-automatic operation)

- Integration with existing decoilers, slitters, and roll formers

- Regional tooling customization

- Safety and ergonomic features (three-dimensional laser protection, retractable side guards)

A double folder like the Stefa VHX not only speeds up production, it reduces labor, minimizes errors, and future-proofs your shop against changing market demands.

Maximizing Production Speed Without Compromising Quality

The latest generation of double folders employs hybrid servo-hydraulic pump technology, blending the power of hydraulics with the precision and energy efficiency of electric drives. This means:

- Simultaneous axis movement for fast positioning

- Idle phases with zero hydraulic consumption—saving energy and reducing wear

- Automated gripper and backgauge systems for hands-off operation

- Big clearance on bending tools for complex profiles

With production speeds up to 30% faster than traditional folders, customers see ROI not just in output, but in reduced rework, lower labor costs, and the ability to take on higher-value projects.

Real-World Results: Customer Success Stories in Metal Roofing Fabrication

I’ve worked with roofing and architectural metal shops from the Midwest to the Southeast who made the switch to double folders. One recent customer in Indiana replaced two aging folders with a single VHX6 (21ft, 2mm capacity). Within weeks, their throughput doubled, labor dropped by 40%, and scrap rates fell below 1%. Another client in Texas used the machine’s customizable tooling to produce region-specific profiles, expanding their product line without adding new machines or staff.

Choosing the Right Double Folder: Expert Guidance for Your Shop’s Needs

No two shops are the same, and there’s no one-size-fits-all solution. My approach is consultative: I compare machine specs, demonstrate automation features, and help you weigh the pros and cons of each option. Whether you’re a high-volume roofing panel producer or a custom architectural fabricator, I’ll help you find the right balance of speed, flexibility, and budget. And as Mac-Tech’s national product manager, I have direct access to the latest models, demo units, and technical support—so you always have an expert in your corner.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing increased downtime, excessive scrap, or can’t keep up with demand, it’s time to look at an upgrade. Newer double folders can often replace two or more legacy machines, freeing up space and labor while boosting output.

How do servo-driven folders compare to hydraulic systems?

Servo-driven (hybrid) folders offer faster acceleration, more precise control, and lower energy consumption. They’re especially effective in high-mix, high-speed environments where accuracy and repeatability are critical.

What’s the difference between a combi-beam and a double folder?

A combi-beam folder can switch between different tool shapes but typically bends in one direction at a time. A double folder bends both positive and negative angles in sequence, cutting handling time and enabling more complex profiles in a single setup.

What are signs a roll forming line is no longer cost-effective?

If you’re seeing frequent breakdowns, inconsistent panel quality, rising maintenance costs, or labor shortages, your line may be costing more than it’s delivering. A modern double folder can often handle more profiles and reduce total cost of ownership.

Can I customize tooling for regional or specialty roofing profiles?

Absolutely. We work with manufacturers to design custom tools that fit your market’s unique requirements—whether it’s snap-lock panels, batten caps, or architectural trims.

Is operator training included with new equipment purchases?

Yes. Mac-Tech provides comprehensive onsite training for operators and maintenance staff, plus ongoing phone and remote support to ensure a smooth transition and long-term success.

If you’re ready to explore how a double folder can boost your metal roofing operation, I’d love to walk you through your options. Whether it’s a hands-on demo, a side-by-side comparison, or a detailed ROI analysis, I’m here to help you get the most from your next equipment investment. Reach out today for a personal consultation—I’ll make sure you get the right solution, at the right price, for your shop’s future.

Get Weekly Mac-Tech News & Updates