As Service and Parts Lead at Mac-Tech, I help shops keep their CNC folding machines and press brakes running safely and accurately with reliable service coordination and properly sourced parts. My priorities are clear diagnosis, fast turnaround, and OEM components that protect your machine’s performance and your team’s safety.

OEM Parts vs Aftermarket: Protecting CNC Folder Accuracy, Safety, and Uptime

Precision bending depends on tight tolerances across the entire folding system. OEM parts are engineered to match the machine’s original specifications, which preserves:

- Geometry and accuracy: Backgauge slides, fingers, linear guides, ball screws, and encoders must align to factory tolerances. Small deviations in aftermarket parts can cause cumulative error, inconsistent hem quality, edge marking, or gauge drift.

- Safety integrity: Light curtains, safety relays, safety PLC modules, and e-stop devices must meet the machine’s certified safety category and integrate correctly with the control. OEM safety components maintain validated stop times and risk-reduction performance.

- Hydraulic reliability: For hydraulic folders and press brakes, OEM seals, filters, and valve components are matched to the fluid type and operating pressures. Non-OEM seals can swell or shed particulate that clogs servo valves and accelerates pump wear.

- CNC control compatibility: Drives, I/O modules, encoders, and HMIs often require specific firmware and parameter sets. OEM electronics arrive at the right revision, with correct connectors and preloaded data where applicable, which prevents painful commissioning delays.

- Warranty and lifecycle support: OEM parts align with maintenance bulletins and design updates. That means fewer rework cycles, validated fit and function, and better long-term machine value.

Aftermarket shortcuts can look attractive in the moment, but the real cost often appears as reduced accuracy, nuisance alarms, safety faults, or unplanned downtime.

Preventative Maintenance with OEM Kits that Extend Machine Life

Planned maintenance is the most cost-effective way to protect accuracy and uptime. I recommend a simple structure tailored to hours of operation and environment:

- Daily to weekly: Clean and inspect fingers and backgauge rails, check tooling and clamping surfaces, verify lubrication levels, and confirm light curtain function tests. Listen for pump whine and drive-cabinet fan noise changes.

- Monthly to quarterly: Check backgauge backlash and alignment, verify fold beam crowning and hinge play, inspect belt or coupling wear, clean drive cabinets, replace control cabinet filters, and back up CNC parameters.

- Semiannual to annual: Replace hydraulic filters and perform oil analysis, change control batteries, test safety circuits for stop time and redundancy, calibrate linear scales or encoders as applicable, and review drive error logs.

OEM PM kits make this straightforward. Typical kits include the correct hydraulic filters, seal and wiper sets for linear guides, belts or couplings, recommended lubricants, cabinet filters, fuses, control batteries, and updated hardware where the manufacturer has issued improvements. Using OEM kits keeps the service checklist aligned with the machine’s revision level and helps ensure that every torque spec, shim, and gasket is exactly right.

Whether the machine is a CNC folder or a press brake, proper lubrication, drive cabinet cleanliness, accurate backgauge alignment, and documented safety checks are the pillars of a stable process.

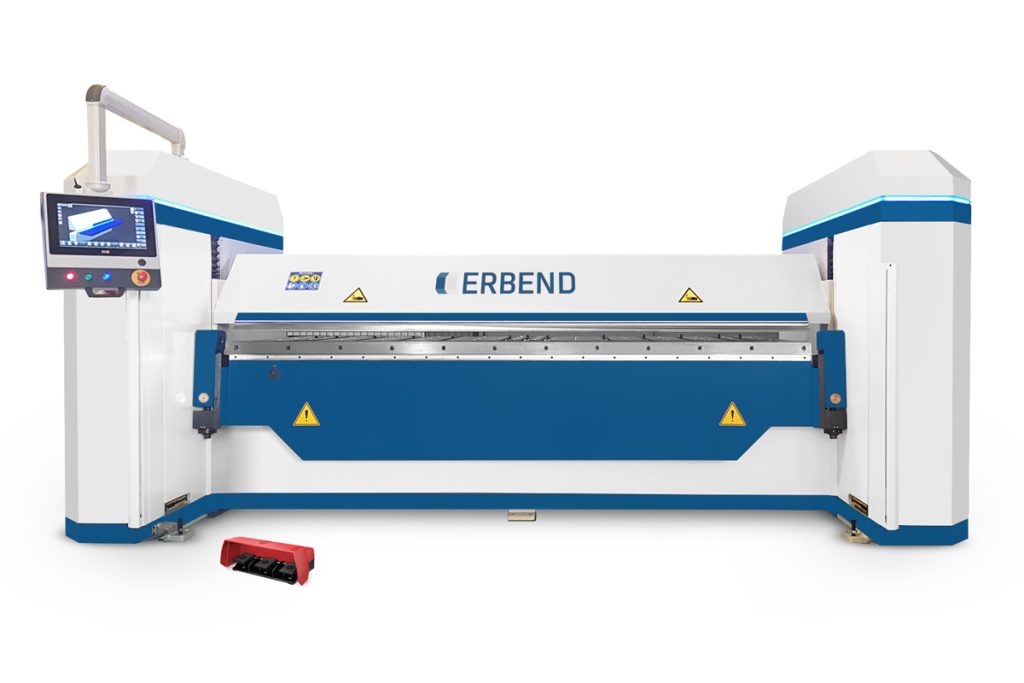

ERBEND MFE METAL FOLDING MACHINE

STEFA VHB620

Fast, Correct Parts Sourcing and Service Coordination with Nicole Salato

My process focuses on clarity and speed:

- Identify and verify: I start with the machine model and serial number, photos of the component, and any fault codes. I confirm the correct BOM revision and check for applicable service bulletins.

- Validate compatibility: For electronics, I verify firmware and parameter requirements, and whether the part arrives preconfigured. For hydraulics and motion components, I confirm dimensions, materials, and torque specs to avoid fit issues.

- Present options: When possible, I offer in-stock items, expedited sourcing, advance exchange on boards, or staged shipment to match your downtime window.

- Coordinate service: If installation support is needed, I schedule a technician, share pre-visit checklists, and confirm required tooling, shims, and calibration blocks so the visit is efficient.

- Communicate updates: You receive tracking, ETA, and concise installation tips or drawings. If we identify a root cause beyond the failed part, I advise on corrective actions and PM steps to prevent recurrence.

My goal is to ship the right part the first time, shorten troubleshooting, and get you back to production with confidence.

Ready for Parts or Support? Contact Nicole Salato at nicole@mac-tech.com

If you need a quote, parts ID help, or service coordination, email me at nicole@mac-tech.com. Helpful details to include:

- Machine model and serial number

- Symptoms, alarms, or photos of the failed component

- Urgency level and allowable downtime window

- Shipping address and preferred delivery speed

I work to align parts availability, technician scheduling, and your production plan so you get a fast and stress-free resolution.

FAQ

How fast can you source OEM parts?

- Italic: Many common items ship same day when ordered before carrier cutoff. Specialty electronics, encoders, and valve assemblies often ship within 1 to 5 business days. I will give you an ETA at quote time and offer expedite options when possible.

How do I know my machine needs service?

- Italic: Early signs include repeatability drift, more re-bends to hit target angle, pump noise changes, slower axis moves, unexpected safety stops, intermittent encoder faults, and inconsistent hem quality. If you see more than one of these, schedule a checkup.

What preventative maintenance should we prioritize?

- Italic: Keep hydraulics clean with timely filter changes and oil analysis, verify backgauge alignment and backlash, maintain correct lubrication on linear guides and screws, clean drive cabinets and replace filters, test safety circuits, and back up CNC parameters regularly.

What is your typical response time and ordering process?

- Italic: I usually respond the same business day. Once we confirm part numbers and shipping method, I send a formal quote. On approval, I place the order, provide tracking, and coordinate technician support if needed.

- Will aftermarket parts affect safety or warranty?

- Italic: They can. Non-OEM safety devices, seals, or control electronics may not meet the machine’s certified performance or may load firmware that conflicts with your control. OEM parts protect safety compliance, accuracy, and warranty coverage.

I am here to help you maintain accuracy, protect your operators, and keep your schedule on track. Reach out anytime for service coordination, parts sourcing, or preventative maintenance support. Let’s keep your machines running like they should.

Get Weekly Mac-Tech News & Updates