As a Sales Executive at Mac-Tech, I’ve spent years working with manufacturers across the Midwest, helping them tackle real-world fabrication challenges. I understand the importance of a reliable work ethic and precision engineering in driving success. Today, I want to share how Rytech Lean Bending Solutions can transform your production line, maximize ROI, and elevate your operational efficiency.

Transform Your Production Line with Rytech’s Precision Engineering

Integrating Rytech brakes into your lean production cells can drastically streamline your manufacturing process. By reducing material handling steps, these solutions enhance workflow efficiency. For example, sequence bending allows operators to perform multiple bends in one setup, minimizing the need for repositioning materials. With offline programming, you can achieve repeatable accuracy, ensuring each piece meets your exact specifications with fewer operators.

Maximize ROI Through Customized Lean Bending Solutions

Rytech offers customized solutions tailored to your specific manufacturing needs, ensuring maximum return on investment. By optimizing your production line with Rytech brakes, you can reduce waste and increase throughput. These machines are designed to fit seamlessly into your existing operations, offering flexibility and scalability as your business grows.

Elevate Operational Efficiency with Hands-On Support

At Mac-Tech, we provide hands-on support to ensure a smooth integration of Rytech solutions into your production line. Our team is dedicated to helping you understand the technical and logistical aspects of these machines. With our support, you can maximize efficiencies and streamline your assembly process, ultimately reducing material handling and labor costs.

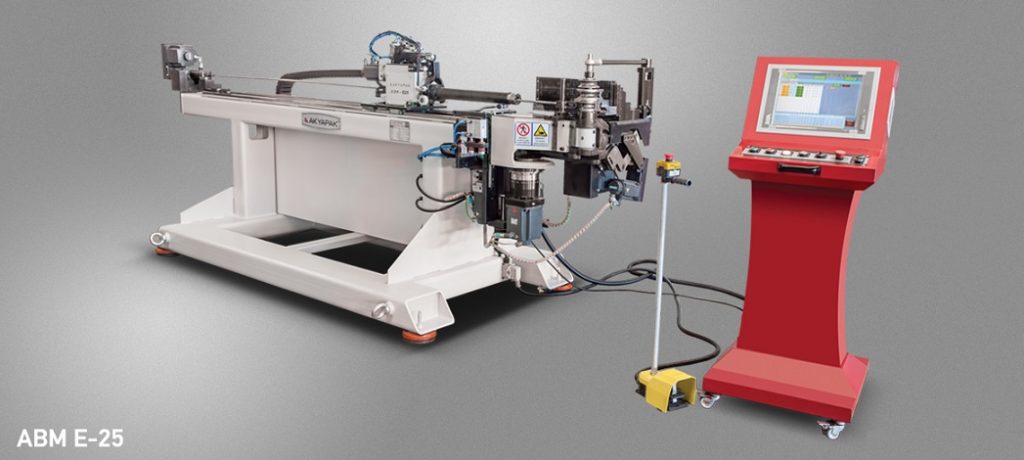

HEAVY DUTY

ABM E-25

Drive Sustainable Growth with Innovative Manufacturing Practices

By adopting Rytech’s lean bending solutions, you position your business for sustainable growth. These innovative practices not only improve your current operations but also set the foundation for future advancements. With Rytech, you can confidently expand your capabilities and meet the evolving demands of the industry.

Strengthen Competitive Edge with Advanced Technology Integration

Incorporating advanced technology like Rytech brakes into your production line strengthens your competitive edge. These machines offer precise control and adaptability, allowing you to deliver high-quality products consistently. By staying ahead of technological trends, you ensure your business remains at the forefront of the manufacturing sector.

FAQ

What are the main benefits of integrating Rytech solutions?

Integrating Rytech solutions reduces material handling, increases efficiency, and ensures repeatable accuracy.

How does sequence bending improve production?

Sequence bending allows multiple bends in one setup, reducing repositioning and increasing speed.

Is offline programming complicated?

No, offline programming is user-friendly and helps achieve consistent results with minimal operator input.

What considerations should I have for machine integration?

Consider space, current workflow, and scalability when integrating new machines.

How do these solutions impact labor costs?

They reduce the need for multiple operators, lowering overall labor costs.

If you have any questions or need further assistance, feel free to reach out. I’m here to help you explore how Rytech Lean Bending Solutions can benefit your operations.

Get Weekly Mac-Tech News & Updates