In the ever-evolving world of metal fabrication, staying ahead of the curve is crucial. As National Product Manager and Regional Sales Executive at Mac-Tech, I’ve seen firsthand how the right equipment can revolutionize workflows and drive efficiency. Today, I’m excited to introduce you to the R3/R3 Plus-Tube Laser Cutter, a game-changer in the industry. This advanced machine offers unparalleled precision, efficiency, and cost savings, making it an invaluable asset for any metal fabrication business.

Revolutionize Your Workflow with the R3/R3 Plus-Tube Laser Cutter

The R3/R3 Plus-Tube Laser Cutter is designed to meet the rigorous demands of modern metal fabrication. With its state-of-the-art fiber laser technology, this machine delivers exceptional cutting precision and speed, allowing you to tackle even the most complex projects with ease. Whether you’re working with steel, aluminum, or other metals, the R3/R3 Plus-Tube ensures clean, accurate cuts every time.

One of the standout features of the R3/R3 Plus-Tube is its versatility. This machine is capable of cutting a wide range of tube shapes and sizes, making it ideal for various applications, from automotive to construction. Its advanced software allows for easy programming and customization, ensuring that you can adapt to different project requirements without missing a beat.

In addition to its cutting capabilities, the R3/R3 Plus-Tube is designed with user-friendliness in mind. The intuitive interface and straightforward controls make it accessible to operators of all skill levels. This means less time spent on training and more time focused on production, ultimately boosting your overall efficiency.

Moreover, the R3/R3 Plus-Tube is built to last. Its robust construction and high-quality components ensure long-term reliability and minimal maintenance. This durability translates to lower operational costs and a higher return on investment, making it a smart choice for any business looking to enhance its metal fabrication capabilities.

Save on Shipping with 40HQ Standard Container Transport

Shipping costs can be a significant expense for any business, but the R3/R3 Plus-Tube Laser Cutter offers a solution. This machine ships standard in a 40HQ standard storage container, which can lead to substantial savings on shipping costs. By optimizing the packaging and transportation process, we ensure that you receive your equipment in a cost-effective and timely manner.

The 40HQ standard container transport not only reduces shipping expenses but also minimizes the risk of damage during transit. The secure packaging ensures that the machine arrives at your facility in perfect condition, ready for immediate installation and use. This attention to detail reflects our commitment to providing exceptional customer service and support.

Furthermore, the standardized shipping container simplifies the logistics of receiving and handling the machine. With clear guidelines and straightforward procedures, you can streamline the process of getting the R3/R3 Plus-Tube up and running in your facility. This means less downtime and a quicker return on your investment.

By choosing the R3/R3 Plus-Tube, you’re not just investing in a high-quality laser cutter; you’re also benefiting from a cost-effective and efficient shipping solution. This holistic approach ensures that you get the best value for your money, from purchase to delivery and beyond.

Enhance Efficiency with Optional Automatic Loading Devices

Efficiency is key in metal fabrication, and the R3/R3 Plus-Tube Laser Cutter offers an optional automatic loading and unloading device that can significantly enhance your workflow. This feature is designed to save processing time, reduce labor costs, and make your operations more streamlined and efficient.

The automatic loading and unloading device is equipped with a hydraulic concave supporting frame, which protects tubes from scratches during the loading and unloading process. This ensures that your materials remain in pristine condition, reducing waste and improving the overall quality of your finished products.

By automating the loading and unloading process, you can free up your workforce to focus on more critical tasks. This not only increases productivity but also reduces the risk of human error, leading to more consistent and reliable results. The time saved can be reinvested into other areas of your business, driving further growth and innovation.

Additionally, the optional automatic loading and unloading device is easy to integrate with the R3/R3 Plus-Tube Laser Cutter. Its user-friendly design ensures a seamless transition, allowing you to start reaping the benefits of increased efficiency almost immediately. This feature is a testament to our commitment to providing solutions that meet the specific needs of our customers.

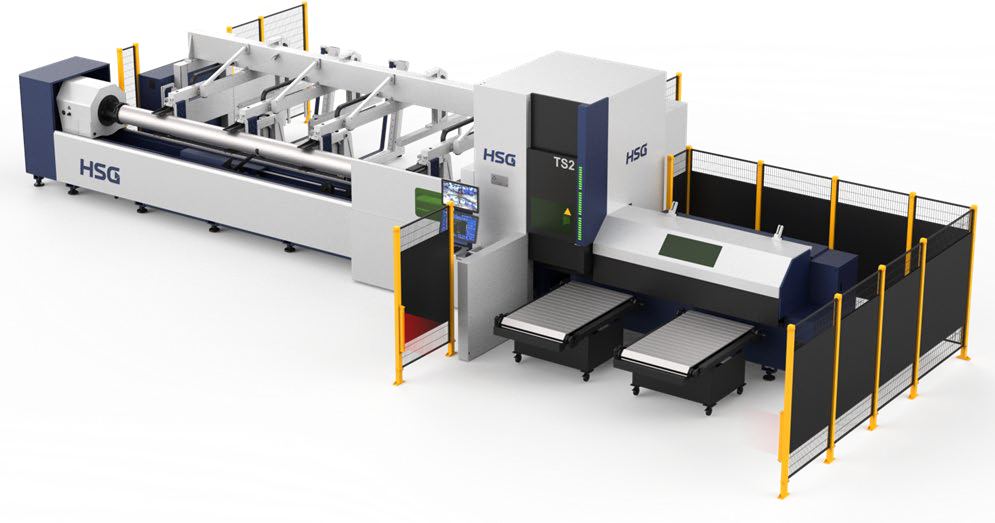

HSG TS2 HIGH SPEED TUBE FIBER LASER CUTTING MACHINE

HSG TS2 V2.0 TUBE LASER CUTTING MACHINE

High-Speed Precision for Advanced Tube Processing

The HSG TS2 V2.0 delivers unmatched efficiency and accuracy in tube laser cutting. Equipped with a 6kW…

Simplify Operations with the HSG-X Bus Control System

The R3/R3 Plus-Tube Laser Cutter is equipped with the HSG-X Bus Control System, a bus-based control system developed by HSG Laser. This intelligent and easy-to-operate system offers effective solutions to common challenges in metal fabrication, such as difficult operation, low efficiency, and high costs.

The HSG-X Bus Control System simplifies the operation of the R3/R3 Plus-Tube, making it accessible to operators of all skill levels. Its intuitive interface and straightforward controls reduce the learning curve, allowing your team to quickly become proficient with the machine. This means less time spent on training and more time focused on production.

In addition to its user-friendly design, the HSG-X Bus Control System enhances the overall efficiency of the R3/R3 Plus-Tube. By optimizing the machine’s performance and reducing downtime, this system ensures that you can maximize your output and meet tight deadlines with ease. The result is a more productive and profitable operation.

Moreover, the HSG-X Bus Control System is designed to minimize operational costs. Its advanced features and intelligent algorithms help to reduce energy consumption and extend the lifespan of the machine’s components. This translates to lower operating expenses and a higher return on investment, making the R3/R3 Plus-Tube a cost-effective solution for your metal fabrication needs.

At Mac-Tech, we understand that every business has unique challenges and requirements. That’s why we’re committed to providing solutions that are tailored to your specific needs. The HSG-X Bus Control System is just one example of how we strive to make your operations more efficient, cost-effective, and successful.

FAQ

What materials can the R3/R3 Plus-Tube Laser Cutter handle?

The R3/R3 Plus-Tube Laser Cutter is capable of cutting a wide range of metals, including steel, aluminum, and other alloys.

How does the 40HQ standard container transport benefit my business?

The 40HQ standard container transport reduces shipping costs and minimizes the risk of damage during transit, ensuring that your machine arrives in perfect condition.

Can the automatic loading and unloading device be added later?

Yes, the optional automatic loading and unloading device can be integrated with the R3/R3 Plus-Tube Laser Cutter at any time, providing flexibility to upgrade as your needs evolve.

What makes the HSG-X Bus Control System user-friendly?

The HSG-X Bus Control System features an intuitive interface and straightforward controls, making it easy for operators of all skill levels to use the machine efficiently.

How does the R3/R3 Plus-Tube Laser Cutter improve efficiency?

The machine’s advanced fiber laser technology, combined with optional automatic loading devices and the HSG-X Bus Control System, ensures faster processing times, reduced labor costs, and higher productivity.

Is the R3/R3 Plus-Tube Laser Cutter durable?

Yes, the R3/R3 Plus-Tube is built with high-quality components and robust construction, ensuring long-term reliability and minimal maintenance.

How can I get more information or a personalized consultation?

Feel free to reach out to me, Patrick O’Neil, at Mac-Tech. I’m here to provide personalized support and help you find the best solutions for your metal fabrication needs.

The R3/R3 Plus-Tube Laser Cutter is more than just a machine; it’s a comprehensive solution designed to revolutionize your workflow and drive your business forward. With its advanced features, cost-saving benefits, and user-friendly design, it’s an investment that will pay dividends for years to come. If you’re ready to take your metal fabrication operations to the next level, don’t hesitate to contact me for a personalized consultation.

Get Weekly Mac-Tech News & Updates